Future Trends and Strategic Development of China’s Packaging Machinery Industry | Embracing Innovation, Safety, and Global Standards

Abstract

As high-tech and innovative technologies increasingly shape global manufacturing, safety and hygiene regulations are becoming international norms and technical trade barriers. The global packaging machinery industry is rapidly evolving through advanced technologies including automation, hygienic design, green design, and integrated systems. In response, China’s packaging machinery industry must adopt five key strategies: foundational development, focused investment, scaling operations, brand building, and innovation, to close the technology gap with leading countries and transition from a large packaging producer to a global packaging powerhouse.

Introduction

Over the past three decades, China’s packaging machinery industry has achieved significant progress due to reform and market opening. However, major gaps remain in scale, innovation, and technical capability. As global competition intensifies, especially in food and pharmaceutical sectors, China faces both opportunities and challenges. To accelerate its growth and competitiveness, China must leverage its market size, address technological shortcomings, follow international trends, and implement strategic policies that support industrial transformation.

1. Global Trends in Packaging Machinery

Since 2011, the global packaging machinery market has become fiercely competitive, driven by two major trends:

-

Increasing integration of high-tech and automation

-

Growing emphasis on safety and hygiene, which are becoming global regulatory standards

Packaging machinery is a vital segment in industrial automation. Emerging technologies such as intelligent CNC systems, digital control, adaptive microcomputers, and power load regulation are enabling continuous, high-speed, and specialized production. These innovations replace outdated production models and shift quality control to full-process monitoring.

Key global trends include:

-

Efficiency & Flexibility: Automation and modular design for rapid production changeovers

-

Digitalization: Smart systems for diagnostics and real-time control

-

Sustainability: Focus on green manufacturing and eco-friendly design

-

Safety & Hygiene: Compliance with ISO and national safety standards is becoming non-negotiable

ISO has introduced safety and hygiene standards for food, pharmaceutical, and packaging machinery. China followed with GB 16798-2007, emphasizing the need for global harmonization to avoid trade barriers.

1.1 Core Technological Advancements

To stay globally competitive, packaging machinery must integrate the following core technologies:

-

Mechatronics and Intelligent Control: Enhances speed, reliability, and automation

-

Microcomputer Systems: Enables adaptive packaging with self-regulating processes

-

Heat Pipe Technology: Improves seal integrity and energy efficiency

-

Component Reliability & Testing: Ensures high performance of pumps, valves, sensors, and motors

-

Computer-Aided Simulation & Design: Optimizes machine architecture

-

Modular Design: Allows fast reconfiguration for diverse packaging needs

-

Self-Diagnostics: Detects and resolves faults in high-speed equipment proactively

1.2 Safety Design in Machinery

Design flaws are responsible for over 80% of operational injuries in packaging equipment. Therefore, machinery must be designed with built-in risk assessments, protective mechanisms, and compliance with GB 16798-2007 to ensure operator safety and reduce accident rates.

1.3 Hygienic Design Considerations

Contamination risks from packaging equipment are primarily due to material selection or poor structural design. To meet modern hygiene standards:

-

Select food-grade materials and coatings

-

Design for easy cleaning and sterilization

-

Integrate sanitary sensors and actuators for real-time safety assurance

1.4 Green Design Innovation

With ISO 14000 driving global environmental policies, countries now impose “green technical barriers” on imported machinery. China must adopt green design strategies that:

-

Minimize environmental impact across the product lifecycle

-

Use recyclable and energy-efficient materials

-

Promote green certifications to unlock international market access

1.5 Integrated Design Systems

China should gather advanced technologies from aerospace, defense, and manufacturing to enhance packaging equipment through:

-

Integration of cutting-edge quality assurance and monitoring systems

-

Advanced filling and vacuum packaging technologies

-

Adoption of AI-based visual inspection and spectroscopic analysis

-

Proprietary, hard-to-replicate technical innovations

2. Development Strategies for China’s Packaging Machinery Industry

To close the gap with global leaders, China must adopt a five-pronged strategic approach:

2.1 Strengthening Core Foundations

Focus areas:

-

Component Quality: Improve the reliability of pumps, motors, sensors, and control systems

-

Material Science: Enhance smelting, metallurgy, and heat treatment capabilities

-

National Standards: Establish comprehensive industry standards beyond the current 30% coverage

-

Testing & Certification: Improve hygiene, safety, and environmental compliance

This foundation supports broader goals in innovation, standardization, and export readiness.

2.2 Prioritizing Key Developments

Packaging machinery is vital to:

-

Transforming China from a packaging country to a packaging power

-

Raising domestic production to reduce reliance on imports

-

Boosting high-tech exports and foreign exchange income

-

Supporting long-term industries like food and pharmaceuticals

China must significantly increase investment in R&D and advanced manufacturing to keep pace.

2.3 Scaling Up Enterprise Capacity

Currently, over 80% of Chinese packaging machinery companies are small or medium-sized, lacking capital and scale. Solutions include:

-

Joint-stock reforms to attract investment

-

Mergers or alliances to increase production capacity

-

Implementation of GMP and market access systems

-

Shift from diverse low-volume production to focused high-volume specialization

2.4 Brand Development Strategy

In global markets, brand recognition drives purchasing decisions. China must:

-

Register strong, legally protected trademarks

-

Use R&D to create unique, high-tech product differentiation

-

Promote through media and industry events

-

Meet green certification standards to compete globally

Firms like Kenwei and Soonture are early examples of Chinese brands gaining recognition through quality and innovation.

2.5 Fostering Innovation

Innovation is essential to long-term competitiveness. Recommended actions:

-

Establish a national R&D center for packaging machinery

-

Increase R&D investment to 5–10% of revenue for large firms

-

Train industry-specific engineers and researchers

-

Build long-term R&D teams integrated with academic and industrial ecosystems

Leading Chinese companies such as Kenwei are already investing in product R&D and market-oriented innovation, setting a positive example.

3. Conclusion

-

Opportunities & Threats: 2011–2015 marked a critical growth window, but the urgency remains. Without rapid improvement in technology, China risks falling further behind global competitors.

-

Strategic Implementation Required: Domestic market demand and export potential offer strong development momentum. Weaknesses in enterprise scale, standards, and innovation must be addressed.

-

Five-Year Objectives: By executing the five outlined strategies, China aims to:

-

Maintain 18.8% annual industry growth

-

Localize high-end packaging machinery

-

Replace imported technologies

-

Enhance reliability, safety, and hygiene standards

-

Expand export capabilities through brand and technical leadership

-

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

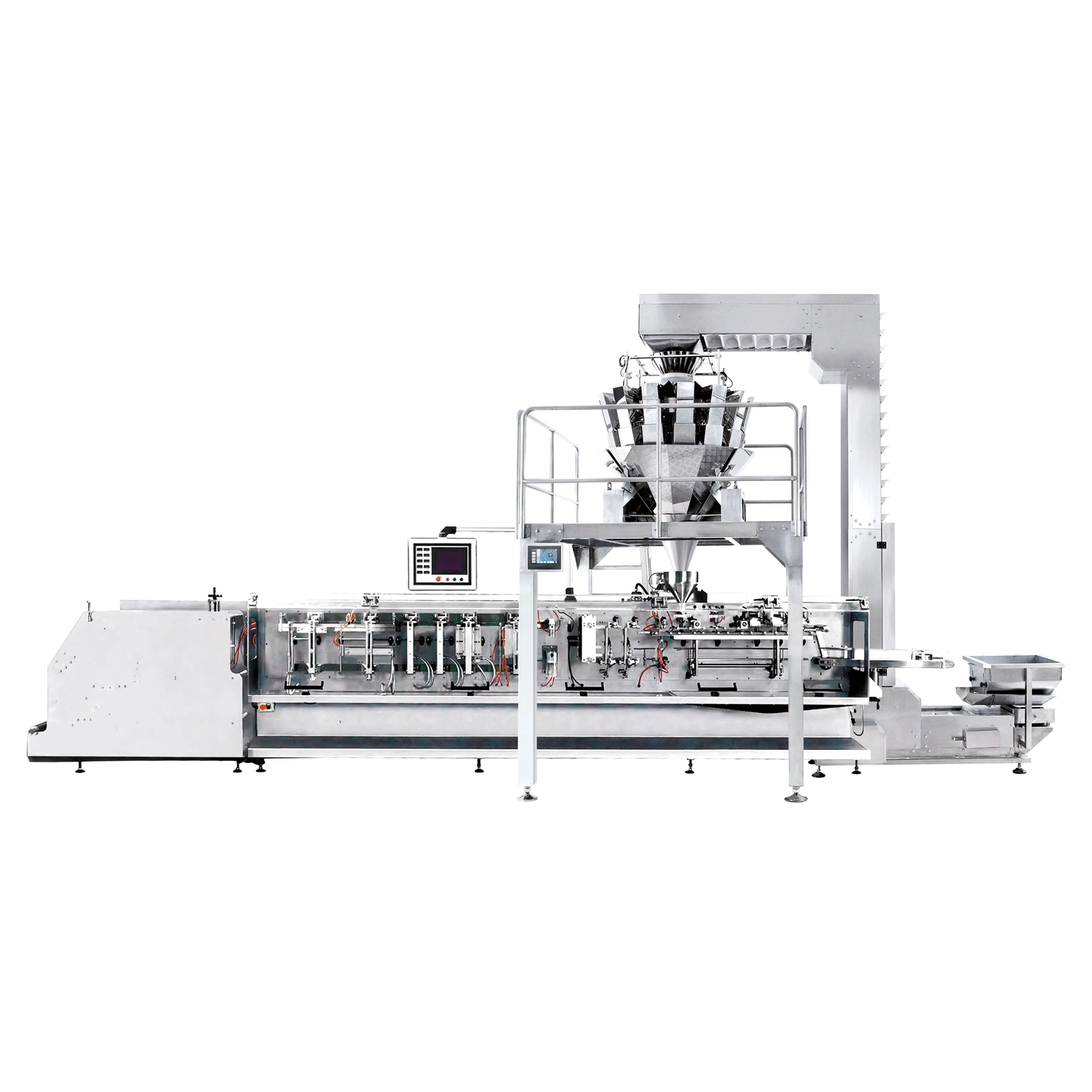

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

The Kenwei JW-B22 Precision Food Packaging Machine with Single Head Bulk Linear Weigher is designed for heavy-duty weighing up to 50kg. It automates feeding, weighing, bag sewing, and output for maximum efficiency. Ideal for grains like corn, rice, soybeans, barley, and wheat, it ensures high accuracy and reliability for the food, chemical, and light industries, making it the top choice for bulk grain packaging.

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei