Sensors, Software and Controls in Modern Packing Machines

- Sensors, Software and Controls in Modern Packing Machines

- Why sensors, software and controls matter for your food packing machine

- Common sensors used on food packing machine lines

- How software turns sensor signals into production value for food packing machine lines

- Control architectures: PLCs, motion controllers and safety systems

- Sensor and control selection: a comparison table for common choices

- How sensors, software and controls improve multihead weighers and packing performance

- Food safety, traceability and regulatory compliance

- Selecting the right food packing machine: key questions to evaluate

- Maintenance, calibration and lifecycle management

- Kenwei — integrated solutions for automated weighing and packaging

- Why choose Kenwei for your food packing machine needs

- How to plan a retrofit or upgrade for older packing lines

- Cost vs. benefit: what ROI looks like for sensorized packing machines

- FAQ — Sensors, Software and Controls in Food Packing Machines

- Q: What sensors are essential on a food packing machine?

- Q: Can I retrofit a modern control system to an older packing machine?

- Q: How often should load cells and metal detectors be calibrated?

- Q: How does software improve multihead weigher accuracy?

- Q: How can I be sure my packing machine meets food safety standards?

- Contact Kenwei / See our products

- Sources and references

Sensors, Software and Controls in Modern Packing Machines

Why sensors, software and controls matter for your food packing machine

Modern food packing machines must balance speed, precision, hygiene and traceability. Sensors provide the raw data (weight, position, presence, metal contamination, vision inspection), software turns data into decisions (recipes, tracking, analytics), and control systems execute those decisions reliably on the production line. Together they reduce giveaway, increase throughput, maintain food safety compliance, and make operations measurable and scalable. If you operate a food packing machine or manage packaging lines, understanding how these components work together is essential to choose, upgrade, or maintain equipment that meets your KPIs.

Common sensors used on food packing machine lines

Sensors are the front-line devices that detect conditions and report them to controllers. Typical sensors deployed on food packing machinery include:

- Load cells and digital scales: Core for weighing applications such as multihead weighers and check weighers.

- Photocells and presence sensors: Detect product or bag presence, trigger actuators and conveyance logic.

- Vision cameras: Used for label verification, fill-level checks, seal inspection and foreign object detection.

- Proximity and inductive sensors: Position sensing for moving parts and packaging components.

- Metal detectors and X-ray: Safety-critical for detecting contaminants in food packaging.

- Temperature and humidity sensors: Important for sensitive products and for validating storage/packing environments.

Each sensor type has trade-offs in cost, accuracy, maintenance and environment suitability (wet, dusty, high-temperature). Selecting sensors that are designed for food environments (IP69K, stainless housings, FDA-compliant materials) is critical for longevity and compliance.

How software turns sensor signals into production value for food packing machine lines

Software sits between the sensors and the human operator, interpreting signals and enabling smarter decisions. Modern packers expect software to provide:

- Recipe management: Rapid changeover between SKUs without manual recalculation of machine parameters.

- Real-time monitoring and dashboards: Visibility into OEE, speed, reject rates and weight distribution.

- Data logging and traceability: Batch records, audit trails and exportable reports for regulatory compliance (e.g., HACCP, FSMA).

- Predictive maintenance: Alerts based on vibration, temperature or performance degradation to reduce unplanned downtime.

- Integration: MES/ERP connectivity for inventory and production planning; OPC-UA, MQTT and standard fieldbuses facilitate data exchange.

For a food packing machine, quality software reduces human error, accelerates changeovers, and converts raw production data into actionable KPIs.

Control architectures: PLCs, motion controllers and safety systems

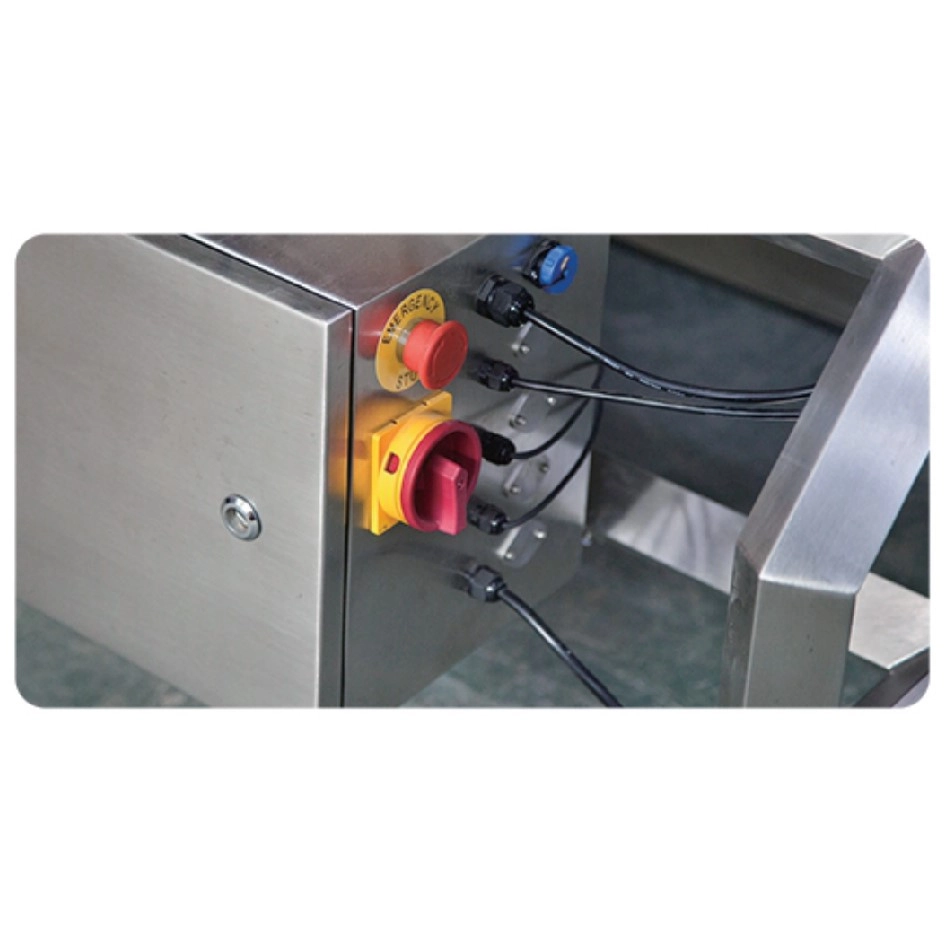

Controls are the execution layer: programmable logic controllers (PLCs), industrial PCs (IPCs), motion controllers, and safety PLCs coordinate physical actions. Key control considerations for food packing machines include:

- Deterministic real-time control: Guarantees synchronization between weighers, conveyors, fillers and baggers.

- Motion control: Smooth acceleration and deceleration for servo-driven feeders and packer heads to avoid product damage.

- Safety integration: Emergency stops, light curtains and safe speed monitoring must be integrated into the control logic without compromising uptime.

- Redundancy and fail-safe modes: Ensures product safety and prevents contamination or mislabeling during faults.

Selecting the right architecture depends on the machine’s complexity: a simple vertical form-fill-seal may need a compact PLC, while a high-speed multihead weighing line benefits from distributed I/O and coordinated motion controllers.

Sensor and control selection: a comparison table for common choices

Below is a practical comparison of commonly used sensors and their typical suitability for food packing machines. (Values are typical ranges and will vary by manufacturer and model.)

| Sensor type | Primary use | Typical accuracy / repeatability | Food-environment considerations |

|---|---|---|---|

| Load cells / Digital scales | Weighing (multihead, checkweigher) | ±0.01%–±0.5% (application dependent) | Sealed stainless housings, IP69K, regular calibration |

| Vision cameras | Label, seal, foreign object inspection | Resolution dependent; sub-millimeter detection possible | Food-safe lenses, washdown-compatible enclosures |

| Metal detectors | Detect ferrous/non-ferrous contaminants | Detect particles down to ~0.5–2.0 mm depending on product | Frequent calibration, sensitivity affected by product effect |

| Proximity / Photocell | Position and presence sensing | High repeatability; milliseconds response | Robust housings, immune to build-up or misalignment |

Source notes for the table are listed at the end of the article.

How sensors, software and controls improve multihead weighers and packing performance

Multihead weighers are a prime example where integrated sensing and control deliver value: high-speed combination algorithms, fast digital load cells, and precise servo-feeding enable consistent portioning with minimal giveaway. Software optimization (combination selection, real-time weight distribution analysis) reduces the number of combinations needed to meet target weights — increasing throughput while minimizing product loss. For operators of a food packing machine, this translates into lower material cost per unit and improved line efficiency.

Food safety, traceability and regulatory compliance

Regulators and customers increasingly demand traceability and documented quality processes. Modern packing machines with integrated sensors and software support compliance by:

- Automatically logging batch numbers, weights, seal temperatures and inspection results.

- Providing time-stamped audit trails for corrective actions.

- Enforcing recipe locks to prevent unauthorized parameter changes.

- Integrating with traceability platforms for end-to-end product genealogy.

These capabilities make it much easier to perform recalls, root-cause analysis, and to satisfy audits from food safety authorities.

Selecting the right food packing machine: key questions to evaluate

When choosing or upgrading a food packing machine, consider the following:

- What is the product type (loose, sticky, fragile, powder)? Sensor and feeder selection depends heavily on product properties.

- What target throughput and accuracy do you need? Higher speeds require faster sensors and more capable control logic.

- How often will you change SKUs? If frequent changeovers are needed, prioritize recipe-driven software and quick mechanical changeover features.

- What are hygiene requirements (washdown, CIP)? Choose seals, materials and sensors rated for those environments.

- What integration is required with upstream/downstream equipment and factory systems (ERP, MES)? Confirm supported protocols and data export options.

Answering these questions helps specify the correct sensors, control architecture and software features for a food packing machine.

Maintenance, calibration and lifecycle management

Maintaining sensor accuracy and software integrity is vital. Best practices include:

- Scheduled calibration of load cells and metal detectors to maintain legal metrology and quality standards.

- Firmware and software update management — test updates in a controlled environment before deploying to production.

- Spare parts planning for critical sensors and actuators to reduce mean time to repair (MTTR).

- Cybersecurity measures for connected machines: network segmentation, authenticated firmware updates and regular vulnerability assessments.

These measures protect both product quality and production uptime for your food packing machine.

Kenwei — integrated solutions for automated weighing and packaging

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.

Our vision is to become the world's leading weighing packing machine manufacturer. Visit our website for details: https://www.kenweigroup.com/

Why choose Kenwei for your food packing machine needs

Combining the technical themes discussed above with Kenwei’s capabilities yields several advantages for buyers:

- End-to-end solutions: Kenwei supplies multihead weighers, linear weighers, combination weighers, check weighers, metal detectors and packing machines, simplifying integration.

- High speed & precision: Machines engineered to minimize giveaway while supporting high throughput.

- Customization & support: One-stop service from design through commissioning, training and after-sales support helps ensure fast ramp-up and lower lifecycle costs.

- Food industry readiness: Equipment designed for washdown conditions, easy maintenance and regulatory documentation to support audits.

Kenwei’s main products include Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, and food packing machinery. Core competitive strengths are high-speed engineering, precision weighing control, integrated quality inspection, flexible customization and comprehensive after-sales service.

How to plan a retrofit or upgrade for older packing lines

Upgrading legacy packing lines with modern sensors and controls can be cost-effective compared to full replacement. Typical upgrade steps include:

- Assess current bottlenecks and compliance gaps.

- Identify which sensors (scales, vision, metal detection) will most improve yield or safety.

- Select control and HMI hardware that can communicate with existing PLCs or replace them with modular systems.

- Validate new software with pilot runs before full deployment and train operators on new recipes and dashboards.

Retrofitting can extend equipment life, improve OEE and reduce giveaway without the capital expense of full line replacement.

Cost vs. benefit: what ROI looks like for sensorized packing machines

Investments in sensors, software and controls typically pay off through reduced product giveaway, fewer rejects, faster changeovers and lower downtime. Example benefits often include:

- Lower material cost per package due to improved weighing accuracy.

- Reduced labor costs from automation and better HMI tools.

- Fewer customer complaints and recalls due to inspection systems.

ROI periods vary by operation but many food manufacturers see payback within 12–36 months depending on production volume, product value and initial system cost.

FAQ — Sensors, Software and Controls in Food Packing Machines

Q: What sensors are essential on a food packing machine?

A: At minimum, a reliable weighing system (load cells), presence/position sensors (photocells), and a metal detector are essential. Vision systems and environmental sensors add quality controls and traceability benefits depending on product and regulatory requirements.

Q: Can I retrofit a modern control system to an older packing machine?

A: Yes. Many controls and sensor upgrades are modular. Evaluate PLC compatibility, available I/O, mechanical constraints and the need for safety system updates. A phased retrofit minimizes production disruption.

Q: How often should load cells and metal detectors be calibrated?

A: Calibration frequency depends on usage and regulations. For high-volume food packing machines, routine calibration monthly or quarterly is common, with verification checks daily. Follow manufacturer and regulatory guidance.

Q: How does software improve multihead weigher accuracy?

A: Advanced combination algorithms, weight distribution analytics and recipe management optimize head selection and feeder timing, reducing the number of combinations and product giveaway while holding target weight tighter.

Q: How can I be sure my packing machine meets food safety standards?

A: Use food-grade materials, washdown-rated sensors, validated metal/x-ray detection, and enable data logging and traceability in software. Maintain calibration records and operate under documented QA procedures (HACCP/FSMA where applicable).

Contact Kenwei / See our products

If you want to explore sensors, software and control configurations for your food packing machine or see Kenwei’s product range (multihead weigher packing machine, metal detector, check weigher, linear weigher, combination weigher, packing machine and more), visit https://www.kenweigroup.com/ or contact Kenwei for a consultation and customized quotation. Our team provides end-to-end solutions from selection to commissioning and after-sales support.

Sources and references

- Mettler-Toledo — Industrial Weighing and Calibration Guidance (industry literature and product pages).

- Packaging World — Articles on vision systems and inspection in packaging.

- Food Processing / Food Manufacturing magazines — Trends in automation and traceability.

- Rockwell Automation — Control architectures and safety PLC best practices.

- McKinsey & Company — Reports on Industry 4.0 and digitalization in manufacturing.

- Sensors Online — Coverage of sensor technology and selection for industrial applications.

- ISO 9001:2015 — Quality management principles relevant to manufacturing processes.

G5020 Food Metal Detector: Ensuring Precision Rejecting Defects

Sustainable Packaging: Combination Weighers Role in 2026

Economic VFFS: ROI and TCO Analysis for Procurement Teams

The B2B Buyer’s Guide to vertical form fill seal machine

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

Rotary Packaging and Weighing System with Multihead Weigher for Peanuts Melon Seeds JW-B8

Kenwei Rotary Packaging and Weighing System with Multihead Weigher is an efficient food packing machine designed for peanuts and melon seeds. This rotary packaging machine ensures high-speed, precise weighing and sealing, making your production smarter and faster.

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

The Kenwei Automatic Canning and Weighing Filling System offers a fully integrated solution for efficient food packaging. Featuring a multihead weigher, Z-type conveyor, vibrator feeder, and capping machine, it automates feeding, weighing, filling, and labeling with high accuracy. Perfect for snacks, puffed foods, fruits, hardware, and granular materials in cans. Ideal for modern production lines.

Single Head Belt Linear Weigher for Vegetable Product Weighing

The Single Head Belt Linear Weigher is constructed from food-grade stainless steel, making it ideal for materials with slight stickiness, such as brown sugar, black sugar, and industrial salt, which have low fluidity. This linear scale features a single hopper with a 15-liter capacity, designed for weighing larger materials efficiently.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei