The Evolution and Application of Multihead Weighers in Modern Automation

This article explores the development, technology, and applications of multihead weighers, focusing on their role in automation. It explains the components and working principles behind these precision weighing systems, highlights key hardware and software aspects, and discusses their growing use in industries like food, pharmaceuticals, and chemicals. Guangdong Kenwei is presented as a leader in providing high-quality multihead weighers for global markets.

With continuous advancements in technology and the increasing demand for automation in various industries, the application of multihead weighers is becoming more widespread. These systems are essential in enhancing efficiency, improving precision, and reducing costs, especially in sectors like food processing, pharmaceuticals, and chemicals. This article breaks down the key aspects of multihead weigher technology, including its hardware, software, and testing procedures, highlighting its advantages over traditional weighing systems.

1. Overview of Multihead Weigher Technology

1.1 Components of a Multihead Weigher

A typical multihead weigher consists of several key components: the loading tray, main vibrating tray, sensor, collecting hopper, and the microcontroller. The microcontroller, which is the core of the system, converts analog signals from the sensor into digital data, processes the weight combination, and sends control instructions. The sequence of operations in a multihead weigher includes feeding, dividing, buffering, weighing, combining calculations, issuing commands, opening the material door, and unloading.

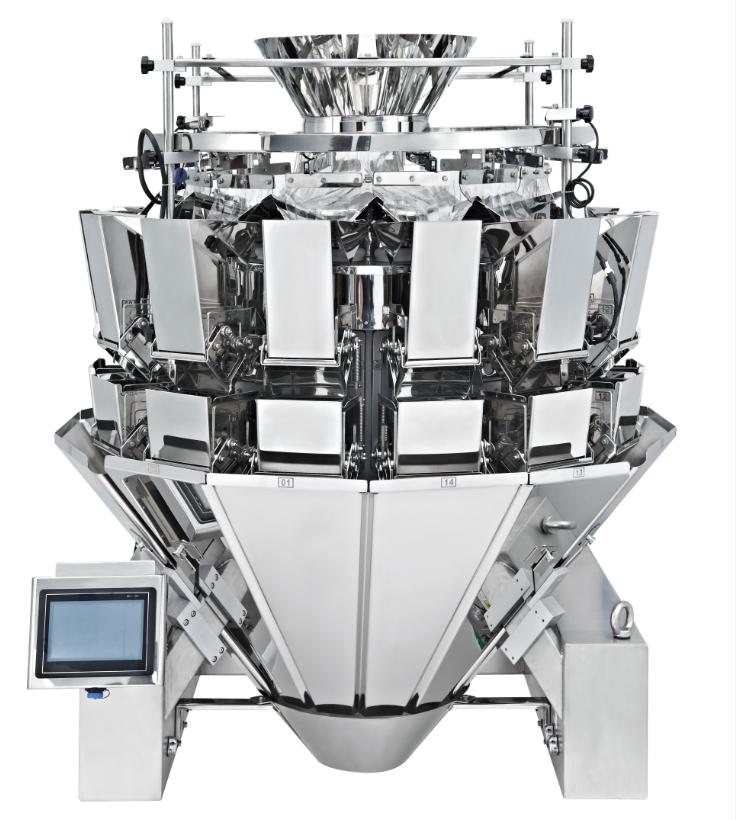

Figure 1: Typical Multihead Weigher Design

The weigher's design ensures precise control over the flow and measurement of materials.

1.2 Weighing Process and Mathematical Calculation

The core principle of multihead weighing involves mathematical arrangement and combination. For example, with multiple hoppers, the system selects a combination of hoppers and their respective weights to match the target value. The formula used to determine the deviation from the total weight follows standard deviation principles, ensuring accurate measurements even when dealing with varying material weights.

The standard deviation formula for calculating the total weight is:

σ=σ1×Ma\sigma = \sigma_1 \times \frac{M}{a}

Where:

-

σ1\sigma_1 is the standard deviation of the material,

-

MM is the quantity of the material,

-

aa is the number of parts being weighed.

For instance, if the standard deviation of a part is 0.3g and the material weight is 240g, the deviation per part is 0.58g, ensuring accurate measurements within -1.16 to +1.16 grams.

2. Key Applications of Multihead Weigher Technology

2.1 Hardware: Ensuring Accuracy

The accuracy of a multihead weigher largely depends on the load cell technology. Load cells contain an elastomer that converts force into deformation, and strain gauges measure the change in resistance. The output voltage is then calculated using formulas that depend on the bridge configuration (single-arm, half-bridge, or full-bridge). Signal amplification and filtering are essential to ensure the signal is strong enough to deliver precise measurements.

To achieve high accuracy and stability, multihead weighers use advanced chips like the ADS158, which ensures smooth analog-to-digital conversion at high sampling rates. The processor speed and power supply also significantly impact the system’s overall performance, with dedicated circuits for each component to minimize interference.

2.2 Software: Optimizing Speed and Accuracy

The software plays a critical role in optimizing both speed and precision. There are two primary types of calculation models:

-

High-Speed Model: This prioritizes quick processing and outputs a combination within an acceptable error range, making it ideal for high-volume applications.

-

High-Precision Model: This focuses on calculating all possible combinations and selecting the one with the least deviation, which is more time-consuming but ensures high accuracy. It is perfect for industries that deal with high-value items like rare medicinal herbs or precious metals.

The system uses real-time data collection, ensuring that each step is completed accurately, with all weighing parameters displayed clearly on an operator-friendly interface.

2.3 Testing: Ensuring Accuracy in Operation

Testing the multihead weigher involves simulating real-life conditions to check for accuracy. For example, a 1000g weight placed on the hopper is observed at different time intervals to see how consistent the readings are. Factors such as vibration and environmental noise can interfere with the weighing process, so ensuring that the system is isolated from such influences is crucial.

Testing shows that even with fluctuations in the environment, multihead weighers can consistently meet accuracy standards, which is key for industries where precision is critical.

3. Future Trends and Prospects of Multihead Weigher Technology

The future of multihead weighers looks promising, especially with the continuous improvement of automation and the increasing focus on precision in production lines. Multihead weighers are expected to expand their applications across various industries like food, pharmaceuticals, chemicals, and hardware. As technology evolves, these systems will become even more integrated into "smart factories" with better real-time data collection, enhanced user interfaces, and improved overall efficiency.

3.1 Global Adoption

Multihead weighers, especially from companies like Guangdong Kenwei, are already making waves globally. With over 1,500 clients in more than 90 countries, Kenwei's products are renowned for their cost-effectiveness and reliability. This trend is likely to continue as more businesses seek automated, precise weighing solutions that align with global production standards.

3.2 Expanding Industry Applications

As demand grows for automated solutions in diverse fields, multihead weighers will continue to evolve. New designs and configurations will emerge, capable of handling increasingly complex materials and applications, from food production to pharmaceuticals and beyond.

Conclusion

The application of multihead weighers in automation has revolutionized weighing technology, offering significant improvements in speed, accuracy, and reliability. As industries demand higher precision and efficiency, the role of multihead weighers will continue to expand. With leading manufacturers like Guangdong Kenwei driving innovation, the future of combination weighing technology is brighter than ever.

Call to Action:

To learn more about how Guangdong Kenwei’s multihead weighers can improve your production processes, contact us today for a consultation.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei