The Growing Demand for Intelligent Combination Weighers in China's Automated Production Industry

This article delves into the development and market prospects of intelligent combination weighers in China. It outlines the structure, applications, and growth of this technology across industries like food and pharmaceuticals, driven by automation trends and rising labor costs.

As automation continues to transform industries across China and labor costs rise, the demand for precise and efficient weighing solutions has skyrocketed. This is especially true in industries such as food, pharmaceuticals, and seeds. The intelligent combination weigher market in China has experienced significant growth, offering great opportunities for both development and innovation.

1. Development Status of the Intelligent Combination Weigher Market in China

1.1 Definition and Structure of Intelligent Combination Weighers

An intelligent combination weigher, also known as a mini multihead weigher or computer combination weigher, is a high-precision weighing device designed for fast and automated weight measurements. The system consists of multiple independent weighing units that work together to calculate and combine the loads of individual components to achieve precise quantitative weighing.

These weighers are available in various configurations, such as 8-head, 10-head, 12-head, and 20-head models, and are designed to handle a wide range of product types, including granular, flake, strip, and irregularly shaped items.

1.2 Structure and Working Principle

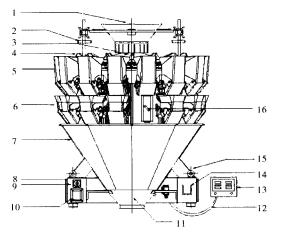

The intelligent combination weigher typically consists of several key components:

-

Vibrating Plate: Moves the product evenly into the hopper.

-

Hopper Part: Includes feed and weighing hoppers for accurate material handling.

-

Control Panel and Sensors: Collect data and convert it into digital signals for precise weighing.

-

Machine Frame: Houses the electrical components and provides stability.

The device operates based on dynamic precision, automatically adjusting based on product type and weight requirements, offering high-speed and high-accuracy performance.

1一infeed funnel 2一level sensor 3一main vibrator 4一linear vibrator pan

5一feed hopper 6一weighing hopper 7一discharge chute 8一Rotary switch

9一Leakage switch 20一machine frame 1l一discharge funnel 12一Monitor cable

13一control panel 14一Display pendant 15一handing ring 16一Aluminum box

2. Development Overview

The intelligent multihead weigher technology originated in Japan in the 1970s. It was designed to optimize the combination of different weights to meet target weight values quickly and accurately. With advancements in load cell technology, the intelligent combination weigher has evolved to handle digital signals, offering greater precision and efficiency.

China's intelligent multihead weigher industry began in 2004, and since then, it has developed into a full-fledged industry with major players such as Highdream Smart and Guangdong Kenwei leading the charge. Domestic manufacturers are able to offer products at 50-70% of the cost of their foreign counterparts, increasing their competitiveness in the global market.

3. Status of Application Areas

The intelligent combination weigher is widely used in various industries, with the food sector being the largest application area. According to market data, the food industry accounts for 78.77% of the domestic demand for intelligent combination weighers in China. Other industries, such as pharmaceuticals, seeds, and tea, make up smaller portions of the market.

As automation and the demand for high-precision weighing grow, the intelligent combination weigher will see expanded use across a variety of industries, including chemicals, feed, and hardware manufacturing.

4. Competitive Landscape

China's intelligent combination weigher market is highly competitive, with both local and international players vying for market share. Foreign companies like Ishida, Yamato, and Anritsu are major competitors, with a strong presence in global markets due to their advanced technology and established reputations.

However, domestic companies like Guangdong Kenwei have gained significant ground, offering competitive products with superior cost performance. Guangdong Kenwei, for example, has exported intelligent combination weighers to over 90 countries and regions, building a strong global presence.

5. Development Prospects of China's Intelligent Combination Weigher Market

5.1 The Rise of Automation

As labor costs rise and industrial automation becomes more widespread in China, the demand for intelligent combination weighers is expected to grow. These systems are particularly useful in industries where speed, accuracy, and consistency are critical, such as food manufacturing, pharmaceuticals, and chemicals.

5.2 Industry 4.0 and Smart Manufacturing

The "Industry 4.0" trend and China's "Made in China 2025" initiative will continue to drive the adoption of intelligent combination weighers in various sectors. As businesses transition to smart factories with fully automated production lines, these weighers will play a key role in enhancing efficiency, reducing labor costs, and improving product quality.

6. Future Development Direction

The future of China's intelligent combination weigher market looks promising, driven by technological advancements and increasing demand for automation. The following are key trends expected to shape the future of the industry:

-

Smart Factories: The shift towards fully automated, energy-efficient, and green manufacturing processes will lead to greater adoption of intelligent combination weighers.

-

Intelligent Warehousing: With increased reliance on automated storage and retrieval systems, the demand for intelligent weighing solutions in warehousing operations will rise.

-

Quality Control and Traceability: As the food and pharmaceutical industries focus more on product quality and safety, intelligent combination weighers will play a crucial role in ensuring traceability and maintaining high standards.

Conclusion

The intelligent combination weigher market in China is poised for significant growth, driven by advancements in automation, rising labor costs, and increasing demand for precision in industries such as food, pharmaceuticals, and chemicals. With the continued development of "Industry 4.0" and smart manufacturing initiatives, intelligent combination weighers will become an integral part of the next generation of production systems.

Call to Action:

For more insights into how Guangdong Kenwei's intelligent combination weighers can enhance your production efficiency, contact us today to learn more about our cutting-edge weighing solutions.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei