Multihead Weigher for Powders and Granules: Preventing Bridging and Dust

- Introduction: Why Bridging and Dust Matter for Multihead Weighers

- Understand the Root Causes of Bridging and Dust

- Particle and Flow Properties

- Moisture and Agglomeration

- Electrostatic Charge and Dust Generation

- Choose the Right Multihead Weigher for Powders and Granules

- Head Count and Accuracy

- Feeder and Weigh-Bucket Design

- Hopper and Transition Geometry: Preventing Bridges at Source

- Mass Flow vs. Funnel Flow

- Surface Finish and Coatings

- Active Anti-Bridging and Flow-Aid Technologies

- Vibrators, Pulsers, and Mechanical Agitators

- Fluidizing Pads and Aeration Systems

- Dust Control: Capture, Containment, and Hygiene

- Enclosures and Local Exhaust Ventilation (LEV)

- Air Knives, Blowers, and Purge Air

- Electrostatic Management and Humidity Control

- Grounding, Ionizers, and Material Choice

- Controlled Humidity and Temperature

- Operation Practices: Feeding Rate, Dosing Strategy, and Maintenance

- Stable Feeding and Speed Settings

- CIP, Cleaning, and Preventive Maintenance

- Testing and Validation: From Lab to Line

- Small-Scale Trials and Data-Driven Tuning

- Why Choose Kenwei for Your Powder and Granule Weighing Needs

- Integrated Solutions and After-Sales Support

- Customization and Compliance

- Conclusion: A Systematic Approach to Preventing Bridging and Dust

- Frequently Asked Questions

Introduction: Why Bridging and Dust Matter for Multihead Weighers

When buyers search for Multihead Weigher for Powders and Granules: Preventing Bridging and Dust, they are looking for reliable, practical solutions to common production problems that affect yield, accuracy, safety, and regulatory compliance. Bridging (material forming a stable arch over a discharge) and dust (airborne fines) reduce throughput, cause inaccurate fills, increase rejects, and create hygiene hazards. For food, chemical, and pharmaceutical packagers, preventing these issues is essential to maintain product quality and meet production targets with automated weighing solutions.

Understand the Root Causes of Bridging and Dust

To solve bridging and dust issues in a multihead weigher for powders and granules, start with root-cause analysis. Common causes include particle properties, moisture, electrostatic charge, and poor hopper/feeder design. Identifying which factors apply to your product guides effective corrective actions and informs the right equipment selection for automated weighing.

Particle and Flow Properties

Powders with fine particle sizes, wide particle-size distributions, or high cohesiveness (e.g., powdered sugar, milk powder, certain chemical powders) are prone to bridging and rat-holing. Granular materials with irregular shapes can interlock and jam. Understanding bulk density, angle of repose, and flow function of your product helps determine whether a standard multihead weigher or a specialized system is needed.

Moisture and Agglomeration

Humidity or slight moisture causes powders to clump and adhere to surfaces, promoting bridges in hoppers and feeders. Controlling upstream conditioning (drying or desiccant use) and local environmental conditions around the weighing machine reduces this risk.

Electrostatic Charge and Dust Generation

Friction between particles and metal surfaces can generate static, causing fines to cling to surfaces or become airborne when dislodged. Electrostatic issues increase dust spread and cause erratic flow. Grounding, ionization, and anti-static materials help prevent this.

Choose the Right Multihead Weigher for Powders and Granules

Selecting an appropriate multihead weigher is a commercial decision with direct impact on productivity. Consider head count, hopper geometry, feeder type, and hygienic design to reduce bridging and dust. Machines should be designed specifically for powders and granules when needed.

Head Count and Accuracy

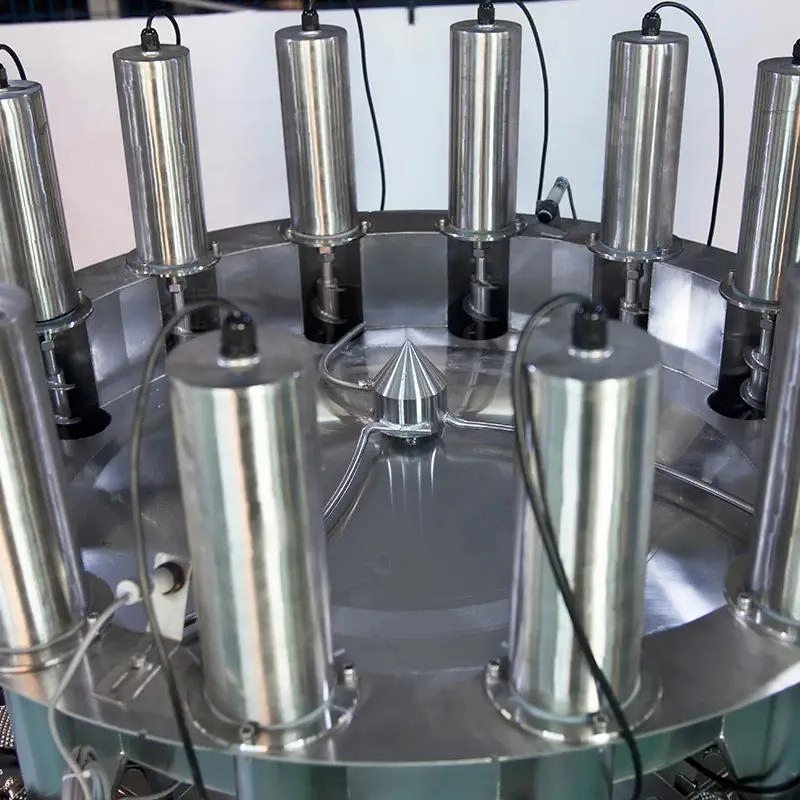

Multihead weighers are available with different head counts (10, 14, 16, 20, 24, 32 heads, etc.). For lightweight powder packs, higher head counts can increase combination choices and help reach target weights with precision—typical achievable accuracies range from ±0.1 g to ±1.0 g depending on product and target weight. Higher speeds are possible without compromising accuracy when the feeder and hopper are optimized for powder handling.

Feeder and Weigh-Bucket Design

Use specially designed feeders for powders: shallow, short feeders with smooth finishes reduce material residence time and minimize compaction. Weigh buckets with gentle slopes and polished stainless steel (304 or 316 where corrosion or product reactivity is a concern) reduce hang-ups and facilitate cleaning. Kenwei offers tailor-made weigh buckets and feeder solutions for powder handling as part of its automated weighing solutions.

Hopper and Transition Geometry: Preventing Bridges at Source

Proper hopper design is one of the most effective ways to prevent bridging. Attention to cone angle, outlet diameter, and surface finish can transform problematic powders into reliably flowing materials on a multihead weigher.

Mass Flow vs. Funnel Flow

Design hoppers to achieve mass flow (all material moves when discharged) rather than funnel flow (material only flows through a central channel). Mass flow reduces dead zones and bridging. Steeper cone angles and larger outlet diameters are typical fixes to encourage mass flow for cohesive powders.

Surface Finish and Coatings

Smoother internal surfaces reduce wall friction. Polished stainless steel or specialized low-friction coatings (food-grade PTFE coatings where allowed) can help materials slide and prevent arching. Maintain hygienic finishes for easier cleaning and lower dust retention.

Active Anti-Bridging and Flow-Aid Technologies

When passive design isn't enough, add active anti-bridging devices and flow aids. These components are often integrated into commercial multihead weigher installations to ensure continuous production.

Vibrators, Pulsers, and Mechanical Agitators

Controlled vibration applied to hoppers or feeder troughs breaks stable arches and helps powders flow. Pulsers that provide short bursts are less likely to cause segregation than continuous vibration. Mechanical agitators or paddle feeders inside hoppers can also prevent bridging for sticky or fibrous materials.

Fluidizing Pads and Aeration Systems

Fluidization uses pockets of air to make powder behave like a fluid, breaking cohesive structures. Perforated pads or aeration rings under product beds are effective for many powders; airflow rates must be tuned to avoid excessive dust. These systems are frequently used with multihead weighers for fine powders.

Dust Control: Capture, Containment, and Hygiene

Dust control protects product quality, equipment, and worker health. For commercial operations using a multihead weigher for powders and granules, implement a combination of containment, extraction, and cleaning protocols.

Enclosures and Local Exhaust Ventilation (LEV)

Enclose feed points and weighing areas and connect them to local dust extraction systems with HEPA or ULPA filtration as required by industry regulations. Negative-pressure enclosures reduce escape of fines into the production environment. Properly sized LEV prevents loss of product and reduces housekeeping needs.

Air Knives, Blowers, and Purge Air

Air knives keep product-flow surfaces clean and free of clinging fines. Purge air around chutes and bagging points prevents material build-up. However, air volumes must be balanced to avoid creating clouds of dust that can escape containment systems.

Electrostatic Management and Humidity Control

Electrostatic charge can make powders cling and create dust problems. Manage static and environmental humidity to stabilize flow behavior for powders and granules.

Grounding, Ionizers, and Material Choice

Ensure machine frames, hoppers, and conveyors are properly grounded. Add ionizers near critical transfer points to neutralize charge. Where possible, choose packaging materials and contact surfaces that minimize triboelectric charging.

Controlled Humidity and Temperature

Maintaining stable low-to-moderate relative humidity (RH) prevents excessive moisture that causes clumping, while very low RH increases static. Monitor and control ambient conditions—dehumidifiers and local climate control around weighing lines can stabilize operations.

Operation Practices: Feeding Rate, Dosing Strategy, and Maintenance

Well-trained operators and optimized recipes are as important as hardware. Operational practices reduce the incidence of bridging and dust during continuous runs.

Stable Feeding and Speed Settings

Match feeder speed to hopper supply and avoid surges that compact material. Variable-speed feeders controlled via PLC let you tune feeding to minimize bridging and segregation while maintaining throughput targets for your multihead weigher.

CIP, Cleaning, and Preventive Maintenance

Regular cleaning reduces dust accumulation that leads to hygienic risks and flow problems. Clean-in-place (CIP) compatible designs with quick-release components reduce downtime. Implement preventive maintenance schedules for vibrators, aeration systems, seals, and filters to sustain performance.

Testing and Validation: From Lab to Line

Before committing to a production configuration, validate with lab or pilot tests. Simulate production speeds, environmental conditions, and packaging weights to confirm that selected measures prevent bridging and dust on your multihead weigher for powders and granules.

Small-Scale Trials and Data-Driven Tuning

Conduct flowability tests (e.g., shear testing, angle of repose) and on-machine trials with representative material. Use weighing logs and reject rates to tune settings. Data-driven adjustments reduce guesswork and drive ROI on equipment investments.

Why Choose Kenwei for Your Powder and Granule Weighing Needs

Kenwei is a powerful manufacturer of multihead weighers with a proven track record in metal detectors, linear weighers, and check weighers. Our machines are characterized by high speed and high precision, and we provide one-stop automated weighing and packaging solutions tailored to prevent bridging and dust challenges for powders and granules.

Integrated Solutions and After-Sales Support

Located in Fusha High-tech Industrial Park, Guangdong, Kenwei offers complete capabilities in design, manufacturing, installation, commissioning, and after-sales service. We work with customers to select appropriate head counts, hopper geometries, and flow-aid options (vibration, fluidization, enclosures, extraction) so your line meets productivity and hygiene targets.

Customization and Compliance

Kenwei provides customization to meet regulatory and industry-specific requirements—food-grade finishes, CIP accessibility, and integrated dust extraction interfaces. Our engineering teams validate solutions on site to make sure multihead weighers operate reliably with minimal bridging and dust.

Conclusion: A Systematic Approach to Preventing Bridging and Dust

Preventing bridging and dust when using a multihead weigher for powders and granules requires a systematic approach: characterize the product, choose the right machine features (head count, feeder and hopper design), use flow aids (vibration, aeration), control electrostatics and humidity, and apply robust dust containment and cleaning practices. Combining good engineering with proper operation and maintenance yields higher throughput, better accuracy, and safer production environments.

Frequently Asked Questions

Q: What is the most common cause of bridging in a multihead weigher for powders and granules?A: The most common causes are cohesive powder properties (fine particles and moisture), inadequate hopper angles or outlet size, and prolonged residence time that leads to compaction. Addressing hopper geometry and adding active flow aids often solves the problem.

Q: Can I run fine powders on a standard multihead weigher?A: Many standard multihead weighers can be adapted for fine powders with the right feeder design, polished surfaces, fluidization or aeration systems, and dust containment. For extremely cohesive or hygroscopic powders, specialized systems or pre-conditioning may be needed.

Q: How do I control dust without reducing weigher accuracy?A: Use local exhaust ventilation, enclosures, and controlled purge air to capture dust while keeping transfer paths short. Ensure extraction airflow is balanced to avoid disturbing product flow into the weigh buckets—Kenwei engineers can help size and tune these systems.

Q: What maintenance practices reduce bridging and dust issues?A: Regular cleaning of hoppers, feeders, filters, and extraction systems; scheduled inspection of vibrators and aeration components; and frequent checks on seals and quick-release parts. Keep maintenance logs and monitor reject rates to detect trends early.

Q: How quickly can Kenwei customize a multihead weigher solution for powders?A: Timeline depends on complexity, but Kenwei offers pre-engineered modules for common powder challenges (hoppers, aeration, enclosures) that speed up implementation. Contact Kenwei via https://www.kenweigroup.com/ for project-specific lead times and on-site evaluation.

Food Packing Machine Solutions for Fresh Produce

Best Food Packing Machine Brands for Multihead Weigher Systems

Why choose a Rotary Packing Machine for high-speed lines

Optimize speed and accuracy on 14 head multihead weighers for pickles

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei