The meat metal detector machine Cost Guide

- Introduction: Why a Meat Metal Detector Machine Cost Guide Matters

- Quick overview of meat metal detector machine costs and value

- Types of Meat Metal Detector Machines and Their Price Ranges

- Table-top and small bench metal detectors (low volume)

- Conveyor belt metal detectors for production lines

- Multi-frequency and high-sensitivity detectors for challenging products

- Integrated systems and turnkey inspection lines

- X-ray systems as an alternative (higher cost)

- Primary Factors That Drive the Cost of a Meat Metal Detector Machine

- Detector technology and sensitivity

- Aperture size and conveyor design

- Construction materials and hygienic design

- Reject mechanisms and automation

- Certifications and validation packages

- Integration and software

- Total Cost of Ownership (TCO) — Beyond the Purchase Price

- Installation, commissioning and validation costs

- Training and operation

- Maintenance, spare parts and calibration

- Downtime, false rejects and product waste

- Return on Investment (ROI) Examples

- Simple ROI scenario for a medium-sized plant

- How to calculate expected ROI

- Buying Strategies: New vs Used, Leasing, and Vendor Selection

- New equipment advantages

- When a used machine makes sense

- Leasing and financing options

- What to look for in supplier contracts

- How to Choose the Right Meat Metal Detector Machine for Your Line

- Questions to ask before buying

- A practical selection checklist

- Installation, Validation and Regulatory Compliance

- Validation and documentation needs for meat processors

- Regulatory considerations

- Why Choose Kenwei for Meat Metal Detector Machines and Integrated Solutions

- Kenwei’s strengths in inspection and weighing systems

- One-stop solutions, customization and service

- Serviceability, spare parts and global support

- Conclusion: Investing Wisely in Meat Metal Detector Machines

- Balancing cost with protection and productivity

- Frequently Asked Questions

Introduction: Why a Meat Metal Detector Machine Cost Guide Matters

Quick overview of meat metal detector machine costs and value

Choosing the right meat metal detector machine is a commercial decision that affects product safety, regulatory compliance, and your bottom line. This guide explains the key cost drivers, realistic price ranges, total cost of ownership (TCO), and procurement tips so you can make an informed investment for your meat processing line.

Types of Meat Metal Detector Machines and Their Price Ranges

Table-top and small bench metal detectors (low volume)

For small butcheries or test labs, bench-top metal detectors offer a compact, lower-cost option. Typical price range: approximately $2,000 to $6,000 depending on brand, aperture size, and features. These are suitable for manually fed samples or small packaging formats.

Conveyor belt metal detectors for production lines

Standard in-line conveyor metal detectors for continuous meat processing are the most common choice. Standard single-frequency conveyor systems typically range from $5,000 to $20,000. Cost depends on aperture width, construction (stainless steel, IP rating), and basic reject mechanisms.

Multi-frequency and high-sensitivity detectors for challenging products

Products with high moisture, variable density, or complex packaging (e.g., minced meat, marinades) often require multi-frequency or advanced signal processing. Expect prices around $15,000 to $45,000 for advanced, multi-frequency meat metal detector machines with improved sensitivity and reduced product effect.

Integrated systems and turnkey inspection lines

When metal detection is combined with checkweighers, multihead weighers, conveyors, and automated reject systems, costs increase. Integrated automated inspection and weighing lines typically cost from $25,000 to $120,000 or more depending on custom configuration, throughput, and automation level.

X-ray systems as an alternative (higher cost)

For detection of low-density contaminants (bone fragments or dense foreign objects in some contexts), X-ray inspection is often used. X-ray systems are significantly more expensive, generally ranging from $60,000 to $250,000+ and are typically considered when metal detection alone is insufficient.

Primary Factors That Drive the Cost of a Meat Metal Detector Machine

Detector technology and sensitivity

Single-frequency machines cost less but can struggle with complex meat products. Multi-frequency or digital signal-processing machines cost more but provide better detection sensitivity and fewer false rejects.

Aperture size and conveyor design

Wider or taller apertures for large cuts or trays require larger coils and heavier-duty construction, increasing material and manufacturing costs. Custom conveyor designs (e.g., hygienic slat belts) also add cost.

Construction materials and hygienic design

Food-grade stainless steel (304/316), IP65/IP66 washdown ratings, and hygienic frame design raise prices, but they are essential for meat processing to meet sanitation standards and extend equipment life.

Reject mechanisms and automation

Simple air-blast or pusher rejects are standard and cost-effective. More sophisticated reject assemblies (swing-arm, drop flaps, automated sorting into separate bins) increase machine cost and complexity, but they reduce downtime and manual handling.

Certifications and validation packages

Factory calibration, certificate of conformity, and validation packages (for HACCP, ISO 22000, or customer audit needs) add to upfront cost but streamline regulatory approval and audits.

Integration and software

Network connectivity, data logging, and integration with MES/ERP systems or Kenwei multihead weighers/checkweighers increase cost but deliver traceability and process control value.

Total Cost of Ownership (TCO) — Beyond the Purchase Price

Installation, commissioning and validation costs

Installation and commissioning (site surveys, mechanical/electrical integration, and validation tests) typically add 5–15% of the equipment cost. For complex integrated lines, on-site support and FAT/SAT may add more.

Training and operation

Operator and maintenance training is often billed separately. Investing in training reduces downtime and false rejects, improving ROI.

Maintenance, spare parts and calibration

Annual maintenance contracts commonly cost 5–10% of equipment value and cover preventive maintenance and calibration. Consumables and spare parts (belts, coils, solenoids) should also be budgeted.

Downtime, false rejects and product waste

Poor detection or excessive false rejects create direct product loss and line stoppages. The cost of a single major product recall can far exceed the initial detector cost—recalls can range from tens of thousands to millions depending on scale—so investing appropriately in inspection technology is a risk-management decision.

Return on Investment (ROI) Examples

Simple ROI scenario for a medium-sized plant

Example (hypothetical): A mid-size plant buys a multi-frequency meat metal detector machine for $30,000. Preventing one moderate recall or a customer complaint that would have cost $50,000 in product loss, shipping, and reputation damage already justifies the purchase. Add reduced labor for manual inspection and lower insurance High Qualitys and ROI often occurs within 12–24 months depending on throughput and product value.

How to calculate expected ROI

Estimate annual costs avoided (recalls, rework, manual inspection labor) + productivity gains. Subtract TCO (purchase + installation + annual maintenance) and divide by TCO to get a simple ROI percentage. Use conservative estimates for recall risk and sensitivity to be defensible in budgeting.

Buying Strategies: New vs Used, Leasing, and Vendor Selection

New equipment advantages

Buying new ensures latest technology (multi-frequency, hygienic design), warranty coverage, and factory validation documents—critical in regulated meat production environments.

When a used machine makes sense

Used detectors can reduce capital outlay but require careful inspection, service history, and recalibration. Consider the availability of spare parts and whether the used unit meets current sensitivity and hygiene requirements.

Leasing and financing options

Leasing spreads capital cost but may carry higher long-term expense. Financing can be attractive for scaling operations or when rapid regulatory upgrades are needed.

What to look for in supplier contracts

Negotiate clear warranty terms, service-level agreements (SLA), spare parts availability, training, and on-site response times. Vendors that provide FAT (Factory Acceptance Test) and on-site validation reduce implementation risk.

How to Choose the Right Meat Metal Detector Machine for Your Line

Questions to ask before buying

Ask these: What is your throughput (products/minute)? What are product sizes and packaging types? Do you need multi-frequency detection? Are washdown and IP ratings required? Will you integrate with Kenwei multihead weighers or checkweighers?

A practical selection checklist

Checklist items: throughput, aperture dimensions, sensitivity target (mm of ferrous/non-ferrous), reject type, hygienic grade (304/316 stainless), certifications, data logging, and integration compatibility.

Installation, Validation and Regulatory Compliance

Validation and documentation needs for meat processors

Most buyers require factory calibration certificates, sensitivity verification, and validation documentation aligned to HACCP and ISO 22000. Keep records for audits and be prepared to demonstrate periodic calibration and functional checks.

Regulatory considerations

Compliance with local food safety authorities (USDA/FSIS in the U.S., EFSA/EU rules in Europe, or other national food safety agencies) is essential. Machines should be installed and validated to meet regulatory inspection requirements and internal quality standards.

Why Choose Kenwei for Meat Metal Detector Machines and Integrated Solutions

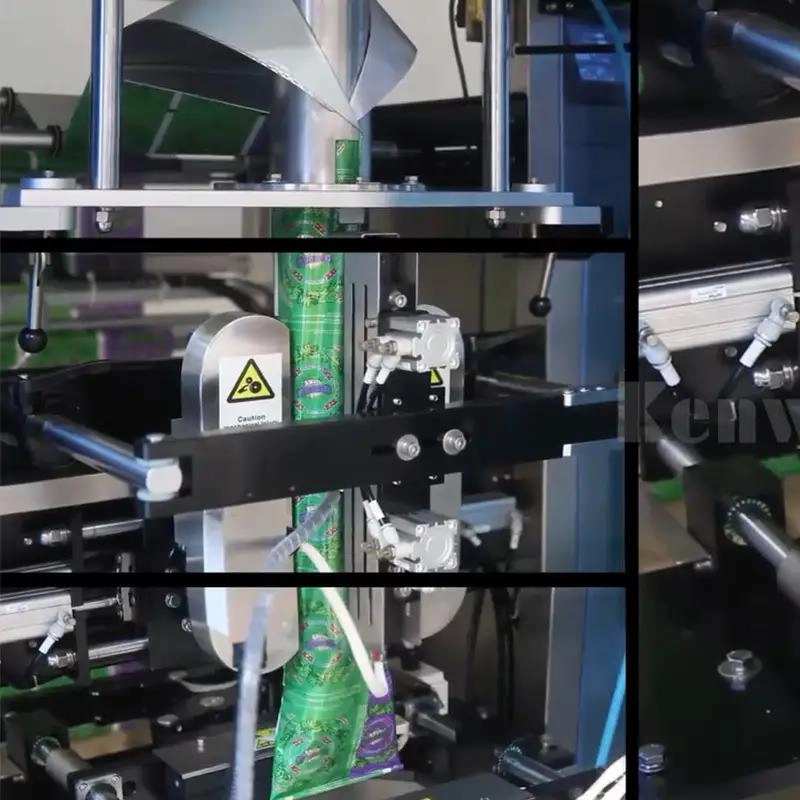

Kenwei’s strengths in inspection and weighing systems

Kenwei is a powerful manufacturer of multi-head weighers and provides a wide range of automated weighing and inspection solutions. Our product lineup includes metal detectors, multi-head weighers, linear weighers, and check weighers characterized by high speed and high precision.

One-stop solutions, customization and service

Kenwei offers one-stop automated weighing and packaging solutions and supports customization requirements. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Guangdong Kenwei provides comprehensive capabilities in design, manufacturing, installation, training, and after-sales service.

Serviceability, spare parts and global support

Choosing Kenwei means access to timely spare parts and technical support, FAT/SAT services, and training that reduce downtime and ensure your meat metal detector machine meets operational and regulatory expectations. Visit https://www.kenweigroup.com/ to explore models and request quotes.

Conclusion: Investing Wisely in Meat Metal Detector Machines

Balancing cost with protection and productivity

Selecting a meat metal detector machine requires balancing upfront cost, sensitivity needs, hygiene requirements, and integration with existing lines. While initial equipment cost varies widely—from a few thousand dollars for bench units to tens or hundreds of thousands for integrated or X-ray systems—smart procurement focuses on TCO, ROI, and risk reduction from recalls and rework. Partnering with an experienced supplier like Kenwei ensures you get the right technology, documentation, and service to protect Kenwei and accelerate payback.

Frequently Asked Questions

Q: How much does a meat metal detector machine cost?A: Costs vary by type and features: bench units $2,000–$6,000; conveyor metal detectors $5,000–$20,000; multi-frequency/high-sensitivity systems $15,000–$45,000; integrated lines $25,000–$120,000+. X-ray systems are significantly more expensive.

Q: Is a meat metal detector machine enough, or do I need X-ray?A: Metal detectors are ideal for metal contaminants and are cost-effective. X-ray systems detect a wider range of foreign objects (dense bones, glass, stones) but cost more. Choose based on product type, risk assessment, and regulatory requirements.

Q: How often do metal detectors need calibration and maintenance?A: Daily in-line functional checks are recommended; full calibration and validation typically every 6–12 months or per company QA protocols. Regular preventive maintenance reduces downtime and keeps detection sensitivity consistent.

Q: Can a metal detector be integrated with Kenwei multihead weighers and checkweighers?A: Yes. Kenwei specializes in integrated weighing and inspection solutions. Integration enables automated rejection, data logging, and streamlined production flow.

Q: Should I buy new or used equipment?A: Buy new for the latest sensitivity technology, hygienic design, and full documentation. Used equipment can save capital but requires careful inspection, service history review, and verification that it meets your detection and hygiene requirements.

Q: What are typical lead times for delivery and installation?A: Lead times vary by model and customization but typically range from 4–12 weeks for new build machines. Integration projects and complex lines may require additional time for FAT, shipping, and on-site commissioning.

Q: How does a meat metal detector machine help prevent recalls?A: By detecting metal contaminants before products reach customers, metal detectors reduce the risk of consumer complaints and recalls. Properly validated machines, combined with HACCP controls and documentation, strengthen food safety programs.

Why choose a Rotary Packing Machine for high-speed lines

How Powder Packing Machines Boost Factory Throughput

Top Features of Fully Automatic Cup Weigher JW-B23

How to Choose a Vertical Packaging Machine for High Throughput

About After Sales Support

How about the after-sales service?

Warranty :2 years

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei