Top 10 multihead combination weigher Manufacturers and Supplier Brands

- Top 10 Multihead Combination Weigher Manufacturers and Supplier Brands

- What is a Multihead Combination Weigher?

- Importance of Choosing the Right Multihead Weigher Brand

- 1. Ishida Co., Ltd.

- 2. Guangdong Kenwei Intellectualized Machinery Co., Ltd.

- 3. Yamato Scale Co., Ltd.

- 4. Multiweigh GmbH

- 5. Anritsu Industrial Solutions

- 6. Bilwinco

- 7. RADPAK

- 8. CCW Technologies (formerly Combi)

- 9. PRECIA MOLEN

- 10. Atoma weighing GmbH

- Key Factors When Selecting a Multihead Combination Weigher Manufacturer

- Weighing Accuracy and Speed

- Customization Capabilities

- Integration and Automation Solutions

- Service and Technical Support

- Global and Regional Reach

- Why Kenwei is a High Quality Choice for Multihead Combination Weigher Solutions

- Frequently Asked Questions

Top 10 Multihead Combination Weigher Manufacturers and Supplier Brands

The multihead combination weigher industry forms the backbone of automated weighing and packaging for food and non-food products worldwide. As an industry expert, I analyze top brands to help businesses select reliable partners for high-speed, high-precision multihead combination weigher solutions. In this comprehensive guide, discover the most reputable manufacturers, their unique strengths, and why Kenwei stands out in a competitive field.

What is a Multihead Combination Weigher?

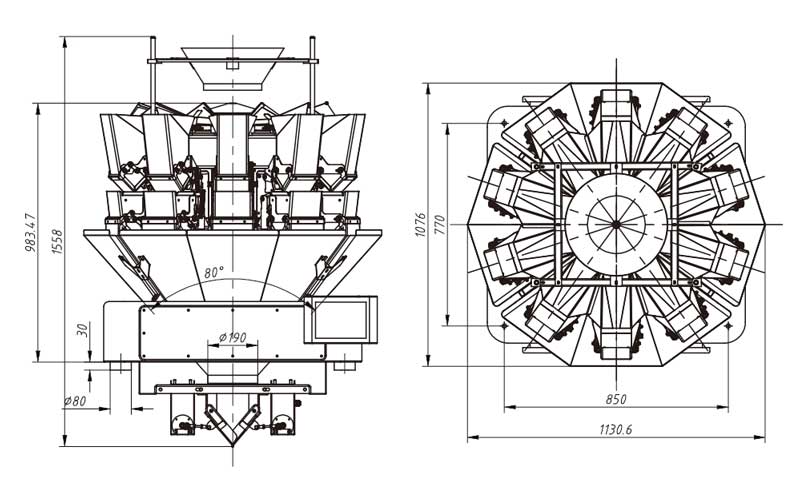

A multihead combination weigher is an advanced, computer-controlled machine designed to weigh products with high speed and precision. It combines the weights from multiple hoppers to ensure the most accurate total for each package. Used extensively in food, pharmaceuticals, chemicals, and other industries, multihead weighers maximize accuracy and output, minimizing product giveaway and packaging time.

Importance of Choosing the Right Multihead Weigher Brand

Choosing the right multihead combination weigher supplier directly influences production speed, weighing accuracy, operational reliability, and after-sales support. Factors like customization options, technology innovation, and global service networks are crucial for businesses seeking seamless integration of automated weighing solutions.

1. Ishida Co., Ltd.

Pioneers in Multihead Weigher Innovation

Founded in Japan, Ishida is widely regarded as the originator of the multihead weigher. Over decades, Ishida has set industry benchmarks for accuracy, durability, and technological innovation. The company's weighers are famous for their longevity, robust design, and cutting-edge software, making them ideal for large-scale food processing operations requiring intricate weighing and packaging.

Key Advantages

- Unmatched accuracy and consistency

- Advanced touchscreen controls and feedback systems

- Extensive global service and training network

- Wide product range, including waterproof and hygienic models

2. Guangdong Kenwei Intellectualized Machinery Co., Ltd.

Expert Chinese Manufacturer with Global Presence

Guangdong Kenwei is recognized as a leading multihead combination weigher manufacturer and a one-stop solution provider for automated weighing and packaging. Located in Fusha High-tech Industrial Park, Kenwei’s strength lies in combining high-speed technology with custom engineering for diverse industries.

Key Advantages

- High-speed, high-precision weighing systems

- Expertise in custom multihead combinational weighing projects

- Complete automation solutions including metal detectors, checkweighers, and linear weighers

- Fast, responsive service and technical support

- Comprehensive R&D and integrated design through installation

3. Yamato Scale Co., Ltd.

Trusted Japanese Precision and Reliability

Yamato Scale is another Japanese titan renowned for accuracy, innovation, and reliability in multihead combination weigher systems. Their weighers cater to a broad spectrum of industries, including snacks, fresh produce, and non-food items.

Key Advantages

- Proprietary software with advanced accuracy algorithms

- Hygienic design compliant with food safety regulations

- Proven track record in both standard and customized projects

- Broad sales and service reach in Europe, Asia, and North America

4. Multiweigh GmbH

German Engineering for Customized Applications

Based in Germany, Multiweigh focuses on developing tailor-made multihead weighing solutions. The brand is highly regarded in European markets and sectors that require specialized, application-driven weighing systems.

Key Advantages

- Modular and flexible machine designs

- Robust construction for demanding environments

- Integration capability with diverse packaging lines

- Competent technical support and in-depth machine training

5. Anritsu Industrial Solutions

High-End Safety and Quality Assurance

Anritsu is renowned for integrating advanced weighing with state-of-the-art inspection solutions. Their multihead combination weighers are especially popular where product safety and traceability are crucial, such as in the pharmaceutical and fresh produce sectors.

Key Advantages

- Smart integration with X-ray and metal detection

- Leading-edge data management and reporting

- High-speed, high-resolution weighing

- Global network for sales and service

6. Bilwinco

Scandinavian Quality for Food Packaging

Based in Denmark, Bilwinco provides inventive multihead combination weigher solutions for protein processing, frozen food, and ready meals. Their weighers emphasize robustness, hygiene, and ease of cleaning.

Key Advantages

- Stainless-steel construction for hygienic applications

- User-friendly operator interface

- Proven expertise in protein and bulk food weighing

- Flexible modular setups

7. RADPAK

European Leader in Integrated Packaging Lines

Poland-based RADPAK specializes in seamlessly integrating multihead combination weighers into complete packaging automation lines, especially for confectionery and bakery industries.

Key Advantages

- Strong focus on full-line automation

- Efficient project management and short lead times

- Flexible configurations for versatile applications

8. CCW Technologies (formerly Combi)

American Innovation in Combination Weighers

CCW Technologies brings advanced automated weighing to North America. Their multihead combination weighers emphasize modularity, open-frame design, and ease of use for small to medium-sized businesses.

Key Advantages

- Flexible configuration options for various industries

- Fast installation and intuitive controls

- Responsive after-sales support in the U.S. and Canada

9. PRECIA MOLEN

French Expertise in Specialized Weighing Solutions

PRECIA MOLEN, based in France, serves industries ranging from chemicals to food processing with high-precision multihead weigher lines.

Key Advantages

- Proven reliability, even in challenging industrial settings

- Customized solutions tailored to client needs

- Comprehensive support and maintenance

10. Atoma weighing GmbH

Precise Engineering for Niche Markets

Atoma, based in Germany, delivers precision multihead weighers suited for niche applications such as small parts, hardware, and pharmaceuticals.

Key Advantages

- Micro-weighing expertise for small-volume products

- Robust construction, adaptable to specialty lines

- Advanced controls and user interfaces

Key Factors When Selecting a Multihead Combination Weigher Manufacturer

Weighing Accuracy and Speed

High precision and speed are essential in modern manufacturing, reducing product giveaway and increasing throughput.

Customization Capabilities

Each business has unique production needs, making the ability to customize hoppers, software, and configurations a critical advantage.

Integration and Automation Solutions

A top manufacturer should offer integration with upstream and downstream packaging and inspection equipment, ensuring seamless automation.

Service and Technical Support

Prompt installation, training, and after-sales service minimize downtime and support ongoing production efficiency.

Global and Regional Reach

Select a brand offering multilingual support, spare parts availability, and engineers skilled in local regulatory compliance.

Why Kenwei is a High Quality Choice for Multihead Combination Weigher Solutions

Kenwei stands out as both a multihead combination weigher manufacturer and a full-solution provider, blending advanced engineering with exceptional customer focus. With comprehensive design, manufacturing, and service capabilities, Kenwei delivers custom, high-speed weighing solutions trusted worldwide. Its expertise in one-stop automation, responsive support, and competitive pricing position it as an industry leader for manufacturers demanding reliability and precision.

Frequently Asked Questions

What is a multihead combination weigher used for?

A multihead combination weigher is used to precisely weigh and dispense products such as snacks, confectionery, meats, frozen foods, and small hardware into packages at high speeds.

How do I choose the right multihead weigher manufacturer?

Consider weighing speed and accuracy, options for customization, integration with other machinery, after-sales support, and overall value based on your production needs.

What distinguishes Kenwei from other multihead weigher brands?

Kenwei combines fast, accurate weighers with R&D strength, full-line automation options, excellent customer service, and flexible custom engineering at competitive prices.

Can a multihead combination weigher be used for non-food products?

Yes, multihead combination weighers are ideal for non-food items like hardware, chemicals, and pharmaceuticals where accurate portioning is required.

Do leading manufacturers provide installation and training?

Reputable multihead combination weigher suppliers, including Kenwei, provide installation, operator training, and technical support to ensure seamless production integration.

Are multihead combination weighers easy to maintain?

Top brands design their weighers for easy cleaning, maintenance, and rapid part replacement to ensure consistent uptime.

What kind of customization can be provided?

Manufacturers like Kenwei offer customization in hopper size, software, feeding systems, and machine layout based on specific product and packaging needs.

How important is after-sales service for multihead weighers?

After-sales service is critical for minimizing downtime and ensuring rapid troubleshooting, spare parts supply, and software updates.

What are common industries using multihead weighers?

Major users include food manufacturers (snacks, dairy, frozen foods), pharmaceuticals, chemicals, pet food, and small parts hardware packagers.

How does a multihead weigher improve packaging line productivity?

By automating accurate weighing and dispensing, multihead combination weighers speed up processing, reduce waste, and ensure consistent pack weights.

Choosing the right multihead combination weigher brand is a significant decision that impacts your operational efficiency and cost-effectiveness. With outstanding precision, high-speed automation, and comprehensive service, Kenwei is set apart as a High Quality global partner in the automated weighing and packaging machinery industry. If reliability, customization, and rapid support are your business priorities, Kenwei is the smart choice for your multihead combination weigher needs.

Top Inspection Strategies Using G5020 Metal Detectors

The latest trends for combination food weigher

Preventive Maintenance for Food Packing Machine Systems

Where to Buy 10 head combination weigher

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

10 Heads Automatic Standard Multihead Combination Weigher 2G

The Kenwei 10 Heads Automatic Standard Multihead Combination Weigher offers precise, efficient weighing for various products. This automatic combination weigher improves productivity and accuracy, making it your ideal 10 heads combination weigher for modern packaging lines.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei