Kenwei Commercial Multihead Weigher — High-Speed Precision

Kenwei Commercial Multihead Weigher — Fast, Accurate, Reliable

Kenwei multihead weighers are designed to help food and packaging businesses boost speed, reduce waste, and ensure consistent product weight. Combining high-speed performance with high precision, our machines are ideal for snacks, dried fruit, nuts, frozen food, pet food, and more.

Why Choose Kenwei?

Kenwei is a leading manufacturer of multihead weighers, metal detectors, linear weighers, and check weighers. Located in Fusha High-tech Industrial Park, Zhongshan, Guangdong, we offer complete automated weighing and packaging solutions — from design and production to installation, training, and after-sales support. Our focus on customization and quick service makes us a trusted partner for companies wanting reliable, scalable packaging lines.

Key Features and Benefits

- High speed: Rapid weighing cycles increase throughput without compromising accuracy.

- High precision: Stable, repeatable results reduce giveaway and save costs.

- Easy operation: Intuitive controls and clear interfaces reduce training time.

- Modular design: Flexible layouts fit a wide range of products and production lines.

- Customizable solutions: Tailored configurations meet special product or packaging needs.

- Complete support: Professional installation, training, and fast after-sales service.

Applications

Perfect for dry, frozen, and fresh products — chips, nuts, candies, vegetables, seafood, and more — Kenwei weighers integrate easily with metal detectors, check weighers, and packaging machines to form a one-stop automated line.

Simple ROI and Lower Waste

By improving weighing accuracy and speed, Kenwei weighers reduce product giveaway and manual handling costs. Faster cycles mean higher output and a quicker return on investment.

Get Started

Contact Kenwei to discuss your product and line requirements. Our team will recommend the best multihead weigher configuration and provide a tailored solution to maximize efficiency and quality. Visit https://www.kenweigroup.com/ for more information.

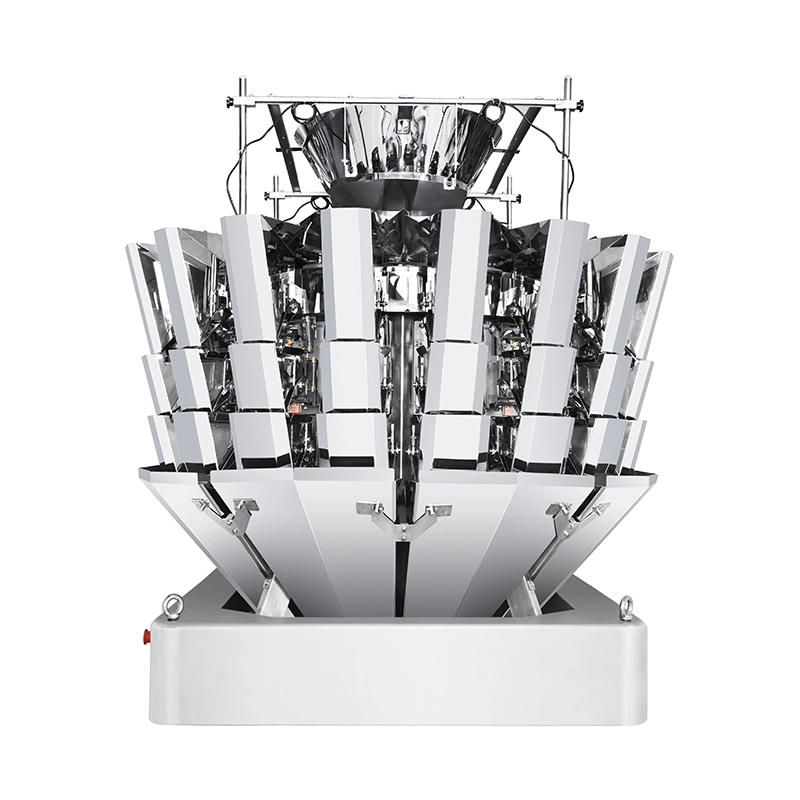

Product Image

Qualification Certificate

TOW Series Combination Weigher-Patent Certificate of Appearance Design

Trademark Certificate-Keiwei Jingwei

Turntable Follow Filling Equipment-Utility Model Patent Certificate

Frequently Asked Questions

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

14 Head Multihead Weigher Packaging Machine for Weighing and Packaging Dumplings Wontons

The weighing sensor has high-precision, high-standard professional performance and adopts intelligent multi-sampling stable mode to significantly improve weighing accuracy. It also has an intelligent fault alarm function, making maintenance more efficient and convenient. The equipment supports high-speed wrong material unloading, effectively avoiding material blockage. The overall structure adopts a highly integrated modular design, integrates CAN bus technology, and applies Modbus industrial standard communication protocol to achieve seamless integration of the combined weighing system and the packaging machine.

High Precision 3-Layer 18-Head Standard Weigher for Accurate and Efficient Weighing

The High-Precision 3-Layer 18-Head Standard Weigher is designed for accurate weighing of a wide range of materials, including granular, flake, round, irregular, and puffed items like nuts, seeds, candies, and snacks. It features a separate vibration plate for mixed material applications, a Ling-shaped hopper for faster and more concentrated discharge, a memory bucket for improved accuracy, and an integrated chassis for enhanced stability. Ideal for high-precision, efficient weighing.

Precision Leak-Proof Multihead Weigher with 3L Hopper for Accurate Small Particle Weighing

The Precision Leak-Proof Multihead Weigher with a 3L hopper is designed for accurate quantitative weighing of small particles like salt, sugar, millet, seeds, and coffee beans. Featuring a leak-proof 3.0L hopper, multi-angle dividing hopper for even material distribution, and a deep U-shaped vibrating plate to prevent leakage. The cast aluminum middle seat enhances strength and reduces weighing stabilization time, making it ideal for fine material applications with high accuracy requirements.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei