Exploring Kenwei’s Multihead Weighers: Versatile Solutions for Every Material

- Standard Multihead Weigher: Ideal for Regular Materials

- Cheese Weigher: Specialized for Sticky Materials

- 14-Head Screw Feeding Weigher: Perfect for Sticky Meat Products

- Second-Generation Linear Weigher: Ideal for Granules and Powders

- First-Generation Check Weigher: Quality Control at Its Best

- Throat Metal Detector: Ensure Product Quality Before Packaging

- Conclusion: Diverse Weighing Solutions for Every Industry

Kenwei’s multihead weighers offer advanced solutions for a wide range of industries, including food, pharmaceuticals, and more. Whether you need a standard weigher for regular materials or a specialized model for sticky products like cheese or meat, Kenwei has you covered. Here’s a closer look at our top models.

Hello, everyone! I'm York, and today I will guide you through some of our featured products, focusing on our multihead weighers. These versatile machines are designed to meet the weighing needs of a variety of industries, including food, pharmaceuticals, and chemicals.

Let’s start with the standard multihead weigher.

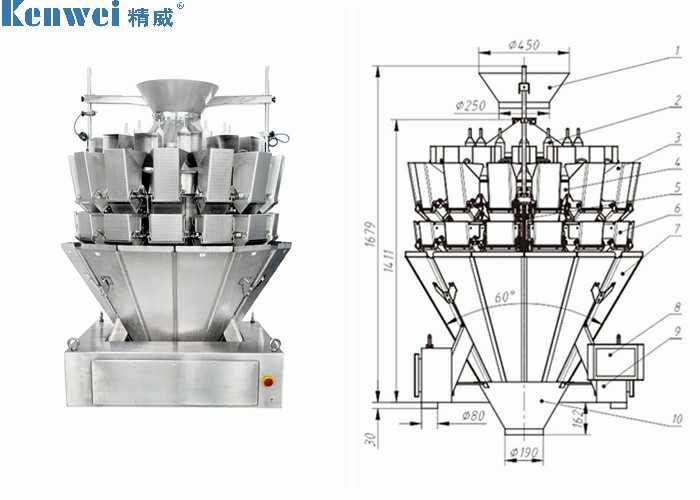

Standard Multihead Weigher: Ideal for Regular Materials

Our 10-head and 14-head multihead weighers are perfect for weighing materials like candy, seeds, jelly, pet food, peanuts, dried fruits, snacks, and more. Here’s a breakdown of their features:

-

Upper Funnel Design:

The standard design features 4 support posts for greater stability. If preferred, we can make it with just 2 posts to reduce costs, though 4 offers more stability during operation. -

Main and Linear Vibrator Pans:

Both are easy to assemble and disassemble for cleaning. The linear amplitude can be adjusted independently during operation for better control. -

Hoppers:

Standard hopper sizes are 1.6 liters and 2.5 liters. These hoppers are also easy to disassemble and clean for convenience. -

Load Cells:

We use high-precision HBM (Germany) or Minebea (Japan) load cells, ensuring accuracy and stability in weighing. -

Screen and Speed:

The 7-inch screen allows you to monitor the machine easily. The 10-head weigher offers a maximum speed of 65 packs/min, and the 14-head reaches 120 packs/min, with accuracy ranging from 0.5g to 1g.Model

JW-A10

JW-A12

JW-A14

JW-AM10

JW-AM14

JW-A10

JW-A14

Identify Code

A10-1-1

A12-1-1

A14-1-1

AM10-1-1

AM14-1-1

A10-1-3

A14-1-3

Weighing Range

10-1000g

10-1500g

10-1500g

100-3000g

100-3000g

10-1000g

10-1500g

Accuracy

X(0.5)

X(0.5)

X(0.5)

X(1)

X(1)

X(0.5)

X(0.5)

Max Speed

65P/M

100P/M

120P/M

50P/M

80P/M

60P/M

100P/M

Hopper Volume

1.6/2.5L

5L

1.6L(No-spring)

Control Panel

7''Touch Screen

Options

Dimple Plate/Timing Hopper/Printer/Reject Device

Driving System

Step Motor

Power Requirement

220V/1000W/50/60Hz/10A

220V/1200W/50/60Hz/10A

220V/1500W/50/60Hz/10A

220V/1500W/50/60HZ/10A

220V/1500W/ 50/60HZ/12A

220V/1000W/50/60Hz/10A

220V/1500W/50/60Hz/12A

Packing Dimension(mm)

1620(L)x1100(W)x1110(H)

1700(L)x1100(W)x1130(H)

1700(L)x1100(W)x1265(H)

1950(L)X1280(W)X1690(H)

2195(L)X1380(W)X1810(H)

1620(L)x1100(W)x1110(H)

1700(L)x1100(W)x1265(H)

Gross Weight

380kg

430kg

490kg

600kg

750kg

380kg

490kg

Cheese Weigher: Specialized for Sticky Materials

Our cheese weigher is designed specifically for soft and sticky materials like cheese, jelly candy, and candied fruits. Key differences compared to the standard multihead weigher include:

-

Rotary Pan:

The rotary pan prevents materials from sticking together, making it ideal for sticky products. The rotary speed can be adjusted to suit different materials. -

Linear Vibrator Pans:

The inclined angle and enhanced amplitude of the linear vibrator pans ensure smoother feeding of sticky materials. -

60° Dimple Discharge Chute:

This chute design reduces sticking issues, offering a better solution compared to the standard 84° chute.

14-Head Screw Feeding Weigher: Perfect for Sticky Meat Products

For sticky materials like meat (chicken, pork, fish, etc.), we offer the 14-head screw feeding weigher. Here’s why it stands out:

-

Screw Feeding:

The screw feeding system replaces traditional vibratory feeding, making it more suitable for sticky materials like meat. -

Drying Device:

The optional drying device helps prevent moisture damage to electrical components, ensuring reliability in humid environments. -

IP65 Waterproof Frame:

The waterproof frame and dimple plate in the material contact area enhance durability and reduce wear over time.

With a max speed of 50 packs per minute and 2.5-liter hoppers, this weigher ensures consistent performance for sticky items.

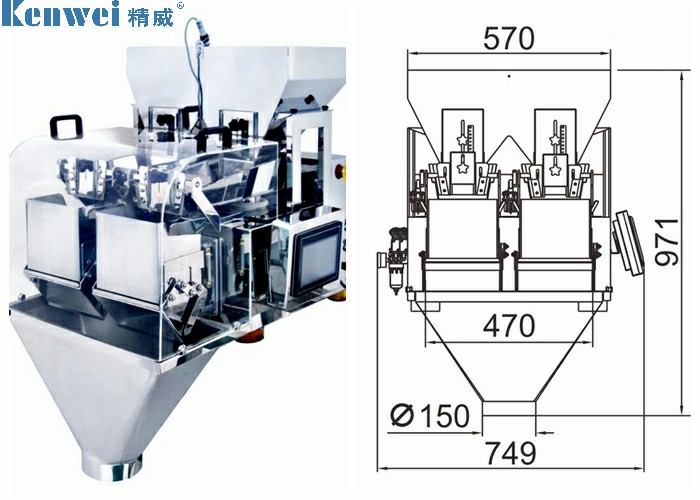

Second-Generation Linear Weigher: Ideal for Granules and Powders

Next, we have our second-generation linear weigher. This model is designed for granule materials like sugar, rice, and coffee powder.

Key features include:

-

Modular Control System:

The new modular control system improves reliability and ease of use. -

Automatic Amplitude Adjustment:

The amplitude can be adjusted automatically for different materials. -

Mixing Capability:

This machine can mix and weigh different products in a single discharge. -

Hopper Size and Speed:

It features 5-liter hoppers and a maximum speed of 30 packs per minute.

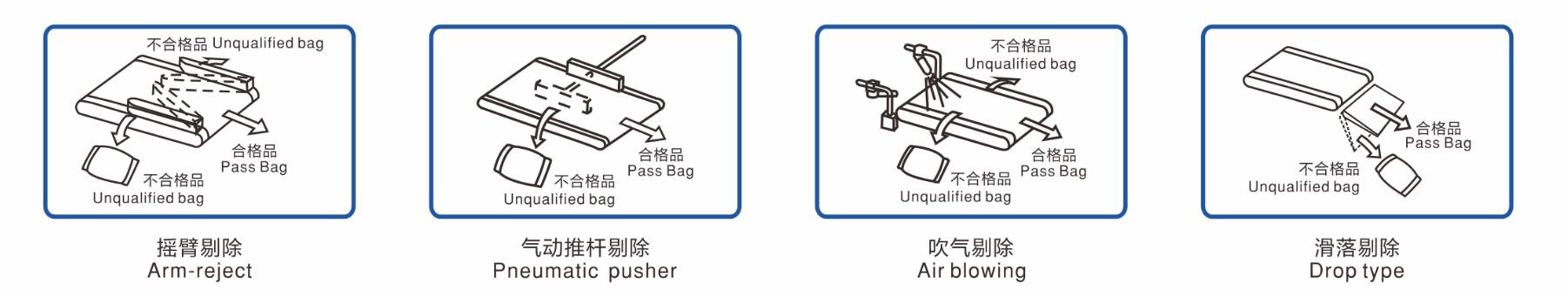

First-Generation Check Weigher: Quality Control at Its Best

For quality control, our first-generation check weigher is an excellent solution. Features include:

-

Intelligent Construction:

The check weigher offers auto program setting for ease of operation. -

Production Records:

It provides detailed production records, helping you track each batch. -

PLC Control System:

The PLC control system with an industry touch screen simplifies operation. -

Reject Methods:

You can choose from various reject methods, including optional collection devices and metal detectors.

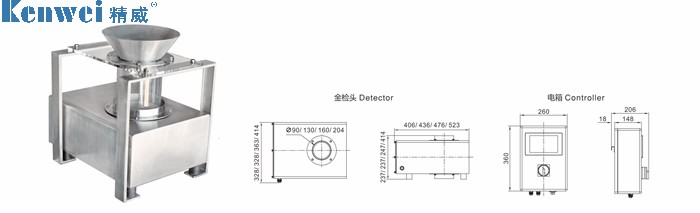

Throat Metal Detector: Ensure Product Quality Before Packaging

For enhanced quality control, our throat metal detector is ideal for detecting metal contamination in products before packaging. This device is installed between the weigher and packaging machine, signaling when an unqualified product is detected.

Conclusion: Diverse Weighing Solutions for Every Industry

Kenwei’s multihead weighers and other machines are designed to meet the needs of industries with varying material types, from sticky foods like cheese and meat to granular products like rice and powder. Whether you require high-speed accuracy or specialized features, Kenwei has the right solution for your business.

Feel free to contact us for more information on our products or to request a customized solution!

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei