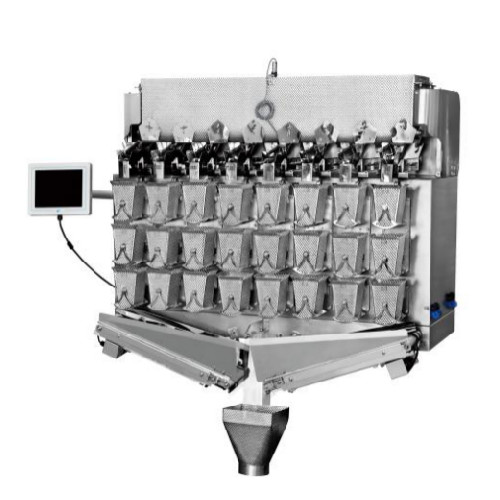

High-precision screw feeding multihead weigher to solve the problem of pickles

As a representative domestic brand in the field of food packaging machine ry, Guangdong Kenwei has been dedicated to the research and development of intelligent multihead weigher for 18 years, breaking through the technological monopoly of imported equipment. With a deep understanding of industry pain points and tailored to the physical characteristics of different materials, Guangdong Kenwei Intellectualized Machinery has created a comprehensive product matrix for automatic weighing and measurement, introducing an intelligent solution for food packaging weighing in the pickle industry:

1. Intelligent anti-blocking system: twin-screw alternate feeding and vane spiral design, the material jamming rate is reduced to 0.3%, which is 5 times higher than that of traditional equipment.

2. Ultra-high-speed metering engine: vibrating plate and screw dual drive technology to achieve a production capacity of 50 bags/minute, which perfectly matches the rhythm of the automated production line.

3. Sticky cracking scheme: scraper-type double-door hopper and 60° blanking chute design completely solve the problem of pickle sticking, especially suitable for assorted vegetables with an oil content of >15%.

4. Military-grade protection system: IP65 waterproof chassis and hexagonal bolt structure, the cleaning time of the equipment is shortened by 60%, and the food weighing and packaging machinery has passed the EU CE certification.

5. High-precision and precise control: The product adopts high-precision special sensors and applies dynamic compensation algorithms to ensure weighing accuracy and operation stability. The weighing error of 100g specification is less than 2.25g, and the annual loss of raw materials is reduced by 83%.

As an innovative benchmark in the domestic multihead weigher field, Guangdong Kenwei Intellectualized Machinery has successively established deep cooperation with many industry-leading manufacturers worldwide. Through the systematic application of intelligent combination scales and supporting food packaging machinery, production efficiency is improved and raw material waste is significantly reduced, ensuring product quality while greatly reducing production waste, easily coping with diverse production scenarios. The products demonstrate strong stability during actual operation, with an annual failure rate consistently controlled within 0.5%, reducing by more than 80% compared to traditional imported models, and maintenance costs simultaneously decreased by 66%. Coupled with an ultra-long 2-year warranty period for the entire machine, it truly achieves a balance between efficient production and long-term operation.

From leading domestic enterprises to global food groups, Guangdong Kenwei Intellectualized Machinery's solutions have served over 1,500 clients worldwide. In the collision between traditional processes and intelligent manufacturing, Guangdong Kenwei Intellectualized Machinery continuously innovates high-precision combination weigher technology, providing cost-effective food weighing and packing solutions for global food industry companies.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

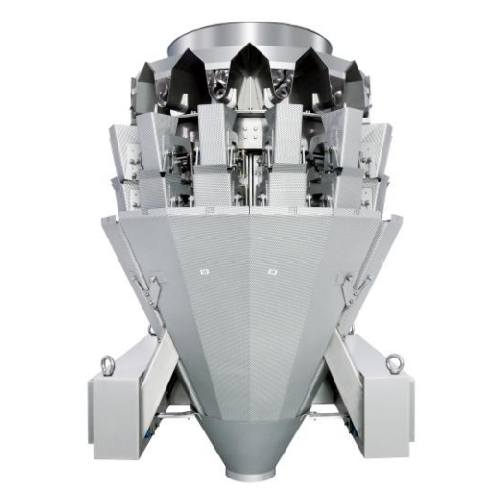

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei