The Role of Coffee Packaging Machines in Modern Coffee Production

- What is a Coffee Packaging Machine?

- How Coffee Packaging Machines Improve Efficiency

- 1. Keeping Coffee Fresh and Flavorful

- 2. Boosting Packaging Speed and Reliability

- 3. Reducing Costs and Labor

- 4. Leveraging Smart Technology

- 5. Supporting Sustainability

- Types of Coffee Packaging Machines

- Factors to Consider When Choosing Coffee Packing Equipment

- Why Choose Kenwei Coffee Packaging Machines?

- Conclusion

The coffee industry depends on efficient packaging to maintain quality, freshness, and productivity. Coffee packaging machines automate the process, reduce costs, and boost efficiency. This article explores how coffee packing equipment works, its advantages, and why Kenwei is a trusted provider of innovative solutions.

What is a Coffee Packaging Machine?

A coffee packaging machine is specialized equipment designed to efficiently pack coffee into bags, pouches, pods, or capsules. These machines automate the packaging process, reducing human error, saving time, and ensuring consistent product quality. By preserving aroma and flavor through advanced sealing methods, coffee bagging machines help extend shelf life and deliver a premium experience to consumers.

How Coffee Packaging Machines Improve Efficiency

Modern coffee packing equipment is more than just a tool for sealing bags. It plays a critical role in ensuring quality, speed, and cost-effectiveness.

1. Keeping Coffee Fresh and Flavorful

Coffee loses its aroma when exposed to air, light, or moisture. Vacuum sealing and nitrogen flushing preserve freshness by slowing oxidation. Advanced multilayer barrier packaging ensures every cup of coffee tastes as fresh as the first brew.

2. Boosting Packaging Speed and Reliability

Manual coffee packaging is slow and inconsistent. Automated coffee packaging machines streamline the process—filling, sealing, and labeling at high speed—allowing producers to meet growing demand while ensuring consistency.

3. Reducing Costs and Labor

Though the upfront cost is significant, a coffee bagging machine reduces long-term labor expenses, minimizes product waste, and improves ROI. With fewer manual errors, businesses achieve higher productivity and profitability.

4. Leveraging Smart Technology

Some advanced models integrate AI and real-time monitoring, automatically adjusting parameters for greater accuracy and efficiency. Automated quality control systems further reduce defective packaging, ensuring consistent results.

5. Supporting Sustainability

Eco-conscious coffee producers benefit from packaging machines that support biodegradable films, recyclable materials, and energy-efficient operation. This helps reduce environmental impact while appealing to sustainability-focused consumers.

Types of Coffee Packaging Machines

Different machines suit different packaging formats:

-

Vertical Form-Fill-Seal (VFFS) Machines: Ideal for whole beans or ground coffee; efficient and fast for bulk packaging.

-

Premade Pouch Fillers: Use branded, ready-made pouches; great for premium packaging with custom designs.

-

Pod & Capsule Fillers: Perfect for single-serve coffee, sealing coffee into airtight pods or capsules to preserve freshness.

Factors to Consider When Choosing Coffee Packing Equipment

When selecting the right coffee bagging machine, businesses should consider:

-

Production Volume: High-output machines for large-scale producers vs. semi-automatic machines for small to medium roasters.

-

Packaging Materials: Flexibility to handle different films and sealing methods (vacuum, nitrogen flushing).

-

Ease of Operation: User-friendly interfaces and automated diagnostics reduce downtime.

-

Customization Options: Machines capable of supporting branded labels and unique package designs help strengthen brand identity.

Why Choose Kenwei Coffee Packaging Machines?

Kenwei provides advanced coffee packaging machine solutions that guarantee accuracy, speed, and product freshness. Key advantages include:

-

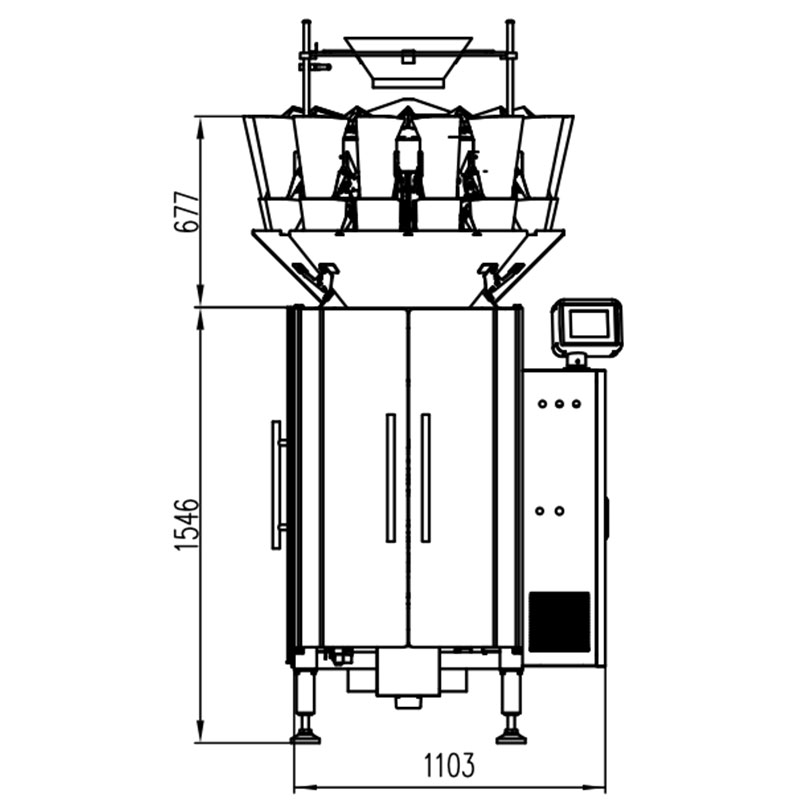

High precision multihead weighers to minimize waste and optimize dosing.

-

Customizable solutions for ground coffee, whole beans, and instant coffee.

-

Integration-ready designs to fit seamlessly into existing production lines.

-

Excellent after-sales service with up to two years warranty and fast technical support.

With over a decade of experience, Kenwei is a trusted partner for coffee producers seeking efficiency and reliability.

Conclusion

Coffee packaging machines are essential for maintaining freshness, reducing costs, and improving productivity in the global coffee industry. From preserving aroma to enhancing speed and sustainability, these machines give coffee producers a competitive advantage.

For innovative, reliable, and customizable coffee packaging solutions, choose Kenwei’s coffee bagging machines. Contact us today to discover how we can optimize your packaging process and keep your coffee fresh from production to cup.

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei