The Role of Packaging Machinery and Automation in Modern Industry

Packaging machinery automates the packing process, improving efficiency, safety, and product quality. This article explores key automation technologies and highlights Kenwei’s precision weighing and packaging systems for stable, accurate, and cost-effective production.

Introduction: What is Packaging Machinery and Equipment?

Packaging machinery refers to mechanical equipment that completes all or part of the product packaging process. By replacing manual labor with mechanical systems, companies can significantly increase production efficiency, meet large-scale manufacturing needs, and maintain high environmental cleanliness standards.

In industrial mass production, packaging is often the final process — yet it plays a vital role in protection, branding, marketing, and sales. Automation not only boosts production capacity and ensures consistent quality but also helps reduce operational costs.

Global Landscape of Packaging Machinery

The packaging equipment industry originated in Europe. Today, countries like Germany, the USA, and Italy lead the global market, backed by strong R&D capabilities, advanced manufacturing, and full product lines. Renowned brands such as Krones, Bosch, and KHS dominate the high-end sector with precision machines and intelligent packaging lines, holding a major share in China’s premium packaging equipment market.

In contrast, most Chinese packaging machinery manufacturers are small to medium-sized enterprises with limited R&D capacity. While domestic brands are still catching up in the high-end segment, China has rapidly become the world’s largest and fastest-growing packaging machinery market, with export volumes increasing year after year.

Key Automation Technologies in Packaging Machinery

Automation technology has transformed the packaging process by improving precision, speed, and safety. Four main technologies drive this evolution:

1. Control Technology

Modern packaging lines often use PLC (Programmable Logic Controller) systems combined with frequency converters.

-

PLC Advantages: Flexible programming, stable operation, strong interference resistance, and high reliability.

-

Applications: Automatic packaging machines, food production lines, and integrated packaging equipment.

2. Display Technology

Automation allows real-time display and monitoring of operational data.

-

Displays convert sensor signals into visual data for operators.

-

Enables quick adjustments, reduces downtime, and minimizes economic losses.

3. Sensor Technology

Sensors bridge automated control and quality testing.

-

Applications include monitoring cleaning, heating, and sealing processes.

-

Improves operational efficiency and ensures packaging quality.

4. Safety Monitoring Technology

Safety is especially critical in food packaging.

-

Includes advanced detection methods to identify defects or contamination.

-

Enhances consumer trust and meets increasingly strict regulatory standards.

Kenwei: Leading in Intelligent Weighing & Packaging Solutions

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is a global manufacturer of intelligent weighing and packaging systems, with an annual production capacity exceeding 7,000 units. Its product range includes:

-

Combination weighers

-

Linear weighers

-

Check weighers

-

Metal detectors

-

Fully automated packaging systems

Kenwei’s Advantages:

-

High-Precision Sensors: German and Japanese brands ensure minimal deviation between actual weight and display values, reducing waste.

-

Advanced AD Modules: 24-bit high-speed chips achieve accuracy as fine as 0.1g for standard scales and 0.01g for micro-scales.

-

Durable Displays: Industrial-grade LCDs with LED backlight offer up to 50,000 hours lifespan.

These features make Kenwei the preferred choice for packaging machinery manufacturers worldwide, combining stability, precision, and cost-effectiveness.

Conclusion

Packaging machinery is more than just a tool for wrapping products — it’s a critical driver of efficiency, safety, and quality in modern manufacturing. With advanced automation technologies and precision engineering, companies like Kenwei are shaping the future of intelligent, automated packaging systems.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

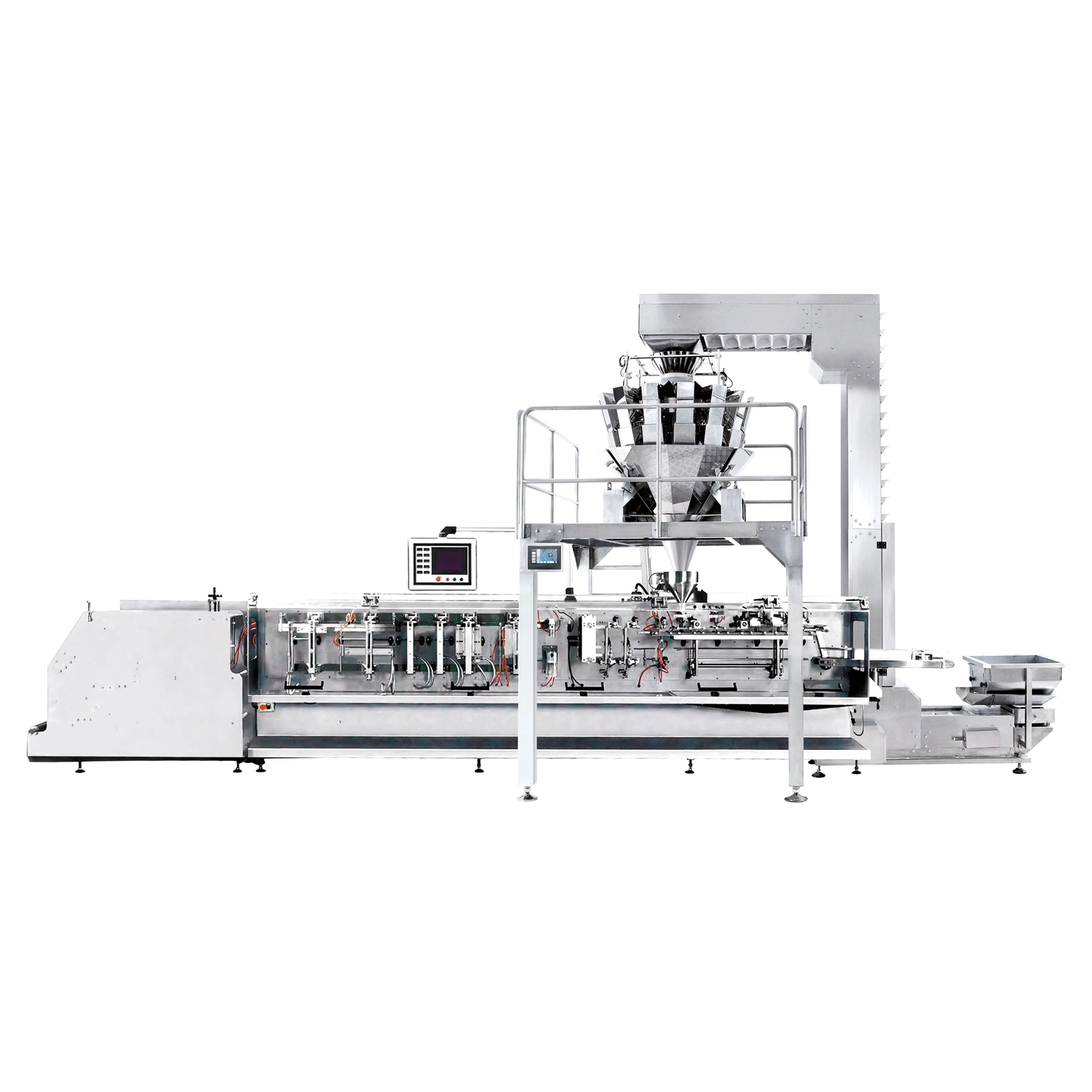

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

The parallel manipulator features a 4-axis linkage structure and a high-precision servo control system, ensuring accurate and reliable operation. It can be integrated with a vision system or onboard conveyor, supporting customized conveying solutions with flexible configuration options. This system is ideal for automated handling of various materials across industries such as food, pharmaceuticals, condiments, plastics, handicrafts, electronics, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei