Kenwei: Expert in Intelligent Weighing and Packaging Since 2006

Discover the advantages of Kenwei in the weighing and packaging industry. As a leading brand, Kenwei delivers innovative solutions for precise weighing and efficient packaging, enhancing productivity and quality for your business's packaging needs.

Since its founding in 2006, Guangdong Kenwei Intellectualized Machinery Co., Ltd. has continuously expanded and innovated. Over more than a decade, Kenwei has achieved significant progress in technology, product development, quality control, and customer service. By outlining our competitive advantages in the weighing and packaging machinery industry, we aim to help customers better understand what sets Kenwei apart.

Strong Technical Team and Engineering Capabilities

Kenwei has built a highly experienced technical team with over ten years of expertise in independent software, electrical, and mechanical design.

-

A rigorous new product development process ensures the stability and reliability of every new product launched.

-

A specialized rapid-response technical team delivers tailored solutions to meet diverse customer needs.

-

A dedicated production process department ensures consistency and stability throughout the manufacturing process.

Superior Product Hardware Design

Our equipment is engineered for durability, precision, and low vibration:

-

The chassis is reinforced with thickened plates and internal bracing, reducing vibration and ensuring high operational accuracy.

-

Key components such as hoppers, vibrating plates, and waterproof covers are manufactured using high-precision molds, delivering exceptional consistency and interchangeability.

-

We use top-tier sensors from renowned brands in Japan and Germany to guarantee precise, stable weighing performance.

-

Industrial-grade PCB design, including optimized layout, high-quality components, and PCBA protection, ensures long-term reliability.

-

Customized product solutions are available for various materials and industries, meeting diverse weighing needs.

Advanced Product Software Design

Kenwei integrates intelligent software systems with industry-proven accuracy:

-

Our software architecture adopts the stable mode of leading Japanese multihead weighers, offering high precision with minimal error.

-

Modbus standard protocol allows seamless integration with different types of packaging machines.

-

Rich functionality and user-friendly features include cleaning mode, simulation testing, free output ports, and multiple combination options.

-

Fully independently developed software systems allow for customized functions to meet unique customer requirements.

Reliable Quality Assurance and Responsive Service

Kenwei is committed to delivering long-term reliability and fast, dependable customer support:

-

We offer a two-year warranty for peace of mind.

-

Our fast-response service team guarantees same-day replies and spare part shipments within 3 days.

-

Each multihead weigher undergoes a 7-day, 24-hour continuous aging test before shipping.

-

All machines and components are carefully documented (serial numbers, photos, matching info) for quick future service.

-

We have upgraded to a full international ERP management system to improve procurement, production consistency, and quality control—ensuring long-term machine performance and stability.

With world-class engineering, precision-manufactured equipment, and unwavering dedication to customer satisfaction, Kenwei is your trusted partner in intelligent weighing and packaging solutions.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

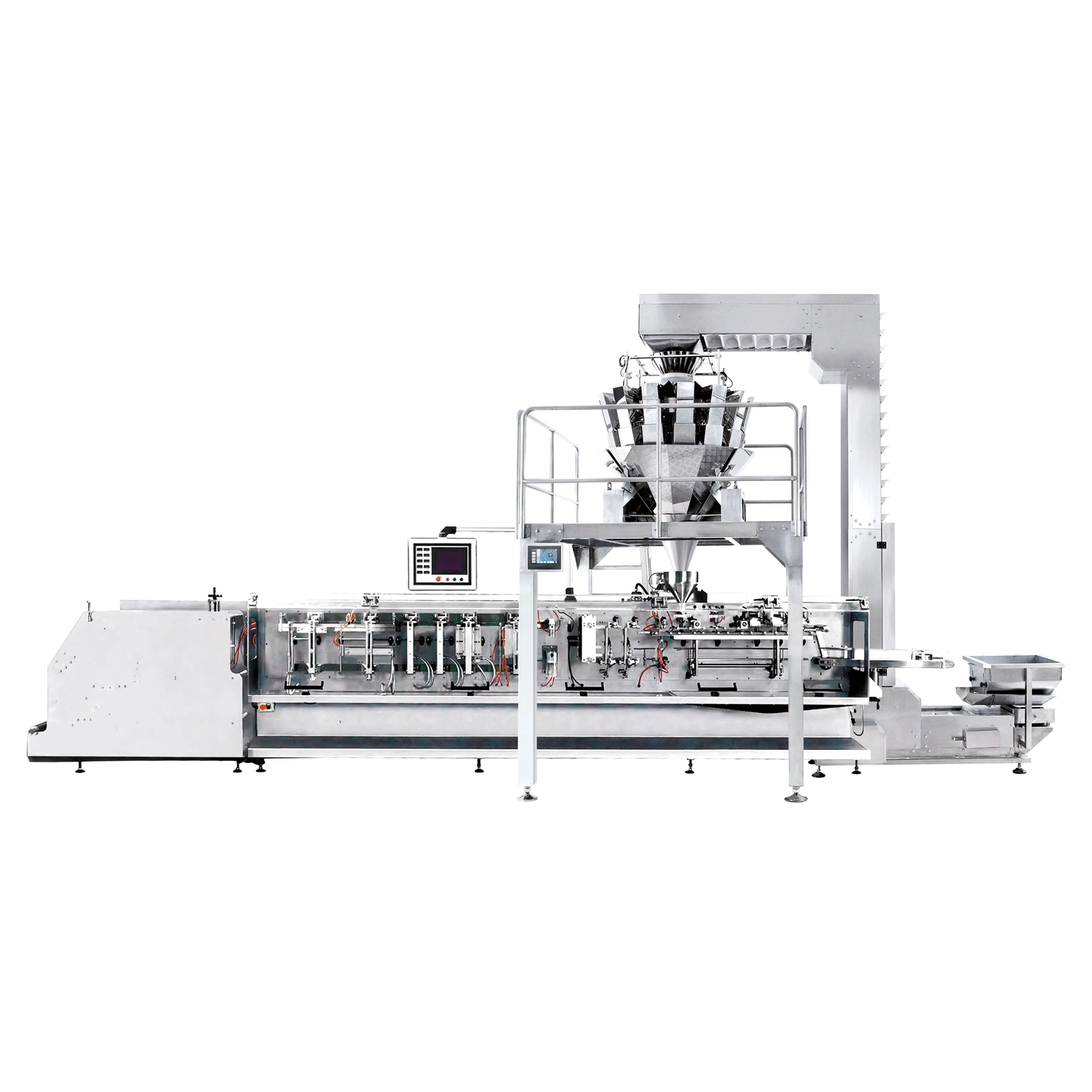

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

The Kenwei JW-B22 Precision Food Packaging Machine with Single Head Bulk Linear Weigher is designed for heavy-duty weighing up to 50kg. It automates feeding, weighing, bag sewing, and output for maximum efficiency. Ideal for grains like corn, rice, soybeans, barley, and wheat, it ensures high accuracy and reliability for the food, chemical, and light industries, making it the top choice for bulk grain packaging.

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei