Powder Packaging Machine Maintenance: Essential Tips for Optimal Performance

Proper maintenance of a powder packaging machine ensures accurate filling, smooth operation, and long service life. This guide covers routine, regular, and special maintenance tasks, including cleaning nozzles and hoppers, checking seals, and inspecting moving parts. Following these steps will reduce downtime, improve packaging quality, and extend the lifespan of your equipment.

A powder packaging machine is essential for efficiently packing powders such as sugar, rice, flour, cornstarch, and other ingredients into uniform containers. Proper maintenance ensures your machine operates smoothly, delivers accurate product quantities, and lasts for years. In this article, we’ll discuss the key knowledge and steps needed to maintain your machine, including routine, regular, and special maintenance tasks.

1. Routine Maintenance for Powder Packaging Machines

Routine maintenance helps keep your machine in good condition and prevents unnecessary breakdowns.

-

Check Belt Tension

The belt should be firm but not overly tight. Excessive tension can cause premature wear and even damage machine components. -

Clean the Injection Nozzles

Nozzles can become clogged with dried powder or debris, affecting dosage accuracy. Regular cleaning ensures consistent filling. -

Inspect for Leaks

Pay close attention to seals and joints to ensure there are no leaks. Tighten or replace seals if necessary to maintain airtight packaging.

2. Regular Maintenance Practices

Beyond daily checks, schedule regular maintenance to ensure efficiency and reliability.

-

Check Belt Tension Weekly

Adjust as needed to prevent operational strain or slippage. -

Clean the Hopper

The hopper, where powder enters the machine, can become clogged over time. Use a safe cleaning agent that won’t damage the surface. -

Inspect Seals and Replace Worn Parts

Worn or damaged seals should be replaced promptly to avoid leaks and contamination.

3. Special Maintenance Tips for Longevity

Special maintenance ensures all components operate at peak performance and extends the machine’s lifespan.

-

Deep Cleaning

Clean all parts of the machine, including internal and external surfaces, walls, and floors. A dirty machine works less efficiently and may cause product quality issues. -

Check All Moving Parts

Ensure gears, belts, and other moving components function properly to maintain accurate filling and consistent packaging. -

Monitor for Abnormalities

Listen for unusual noises and watch for irregular movements. Early detection of malfunctions can prevent costly repairs.

4. General Packaging Machine Maintenance Tips

-

Clean Regularly: Use mild soap and water or a commercial cleaning agent for both the interior and exterior.

-

Inspect Seals and Gaskets: Ensure they are intact and not leaking. Replace if necessary.

-

Maintain Lubricants: Keep lubricants in good condition and properly sealed to prevent leaks and wear.

Conclusion

By following these powder packaging machine maintenance guidelines—covering routine, regular, and special tasks—you can keep your machine in optimal condition. This not only improves efficiency and accuracy but also reduces downtime and repair costs. Consistent care ensures your machine delivers top-quality packaging for years to come.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

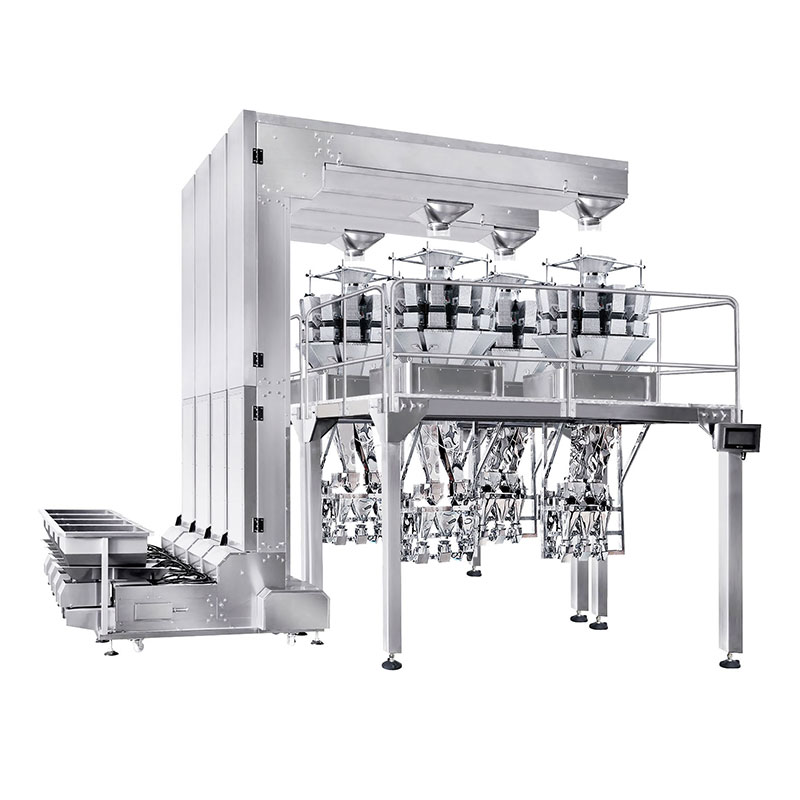

The Kenwei JW-B19 Semi-Automatic Vacuum Feeding Linear Weigher is ideal for precise weighing of powders and small granules like sugar, salt, rice, coffee, and milk powder. With full automation, high accuracy, and space-saving design, it boosts efficiency while reducing labor and cost. Perfect for industries needing reliable, flexible, and compact weighing solutions.

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei