Understanding Multihead Weighers: Types, Functions, and Applications in Packaging

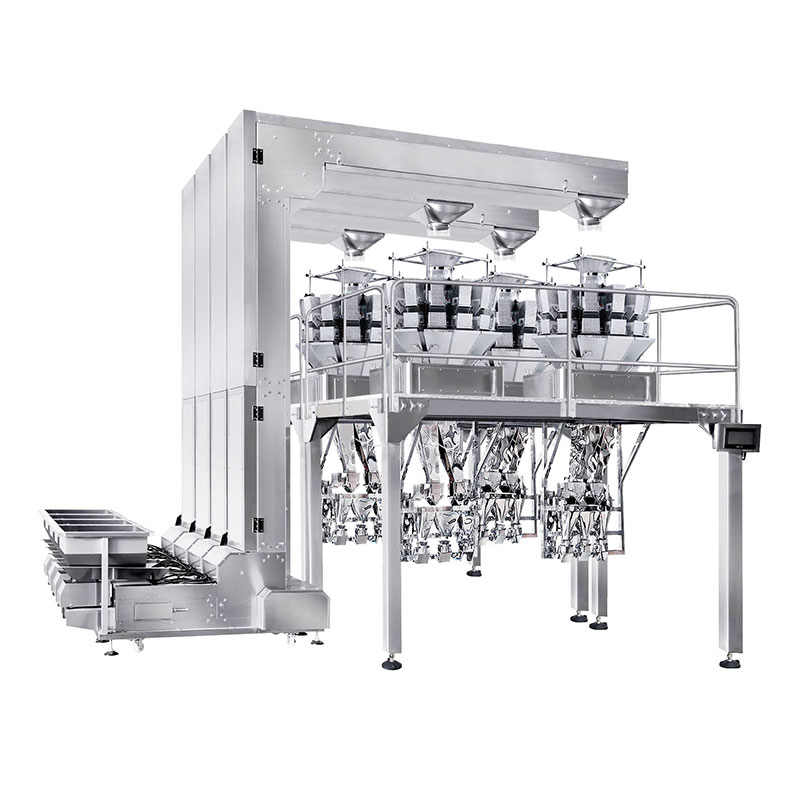

A multihead weigher is a high-precision industrial weighing machine widely used in modern packaging lines for products like coffee, cereals, nuts, grains, and confectionery. Designed with multiple weighing heads and advanced sensors, it delivers exceptional speed and accuracy, making it ideal for high-volume production environments. This article explores the structure, types, and uses of multihead weighers, helping businesses choose the right solution for their packaging needs.

What is a Multihead Weigher?

A multihead weigher is an advanced industrial weighing machine equipped with multiple weight sensors, or "heads," arranged to measure products in succession. This technology is commonly integrated into packaging lines for weighing and packing dry goods such as coffee, cereals, nuts, grains, candies, and other products requiring precise weight control.

These machines are designed to combine speed, accuracy, and efficiency, making them a vital component in automated packaging systems.

Structure of a Multihead Weigher

A multihead weigher consists of two primary components:

-

Scale Base – Houses the load cells that measure product weight and the control panel that processes data.

-

Discharge Device – Usually a vibratory hopper or funnel that guides the weighed product into one of the weighing heads before packaging.

The combination of these components allows for rapid, consistent, and highly accurate weighing, even at high production speeds.

Types of Multihead Weighers

Different types of multihead weighers are designed for specific applications and product characteristics:

-

Gravity Multihead Weighers

Use gravity to measure products, ideal for loose items like fresh fruits and vegetables. -

Pneumatic Multihead Weighers

Use air pressure for weighing, often chosen for pharmaceuticals and applications requiring extreme precision. -

Electronic Multihead Weighers

Utilize electronic sensors to measure products quickly, commonly used for conveyor belt packaging lines.

Applications of Multihead Weighers

Multihead weighers are widely used in high-volume production environments where speed and accuracy are crucial.

Common uses include:

-

Food production: snacks, confectionery, frozen foods, dried fruits, coffee, grains

-

Pharmaceuticals: capsules, tablets, powders

-

Non-food items: hardware, plastic components, small automotive parts

Their ability to weigh multiple items simultaneously while maintaining consistent accuracy makes them essential for industries seeking cost efficiency and product quality control.

Conclusion

Whether in food manufacturing, pharmaceuticals, or general packaging, a multihead weigher offers unmatched speed and accuracy. Although these machines require a higher investment, their long-term benefits in productivity and precision make them a valuable asset for high-volume operations.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About After Sales Support

How about the after-sales service?

Warranty :2 years

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

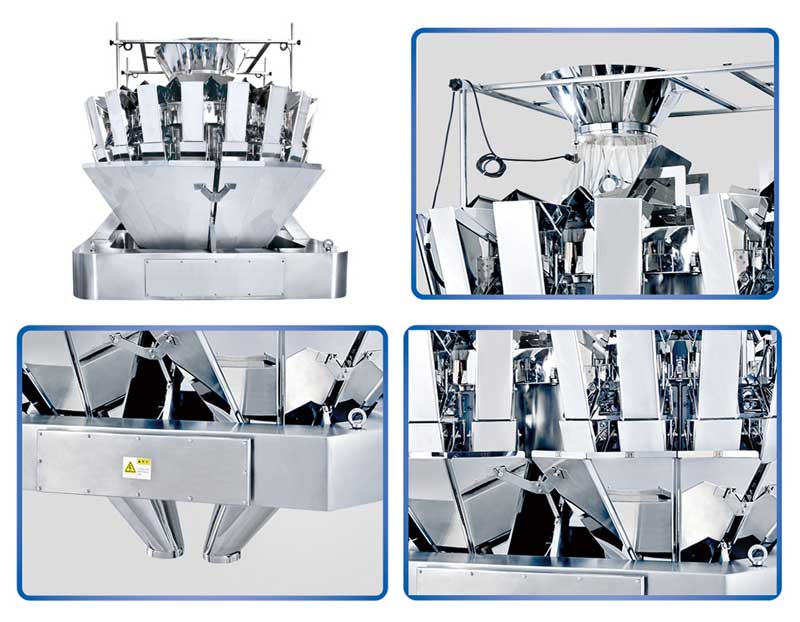

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei