How to Choose the Best Automatic Packaging Machine for Your Business

- Types of Packaging Machines

- 1. Semi-Automatic Packaging Machines

- 2. Automatic Packaging Machines

- Key Tips for Choosing the Right Packaging Machine

- 1. Price and Features

- 2. Product Compatibility

- 3. Physical Appearance of Products

- 4. Material and Freshness Preservation

- 5. Maintenance and Cleanliness

- Conclusion

Choosing the right packaging machine can save time, reduce costs, and improve product presentation. This guide explains the differences between semi-automatic and automatic packaging machines, along with key tips for selecting the right one, from pricing and product compatibility to materials and maintenance.

For small businesses, packaging is more than just wrapping products—it’s a way to save time, reduce shipping costs, and enhance brand presentation. The right packaging machine can streamline operations and improve product quality. In this article, we’ll compare semi-automatic and automatic packaging machines, then share practical tips for selecting the best one for your needs.

Types of Packaging Machines

1. Semi-Automatic Packaging Machines

Semi-automatic machines are ideal for businesses looking for flexibility at a lower cost.

Tips for Using Semi-Automatic Machines:

-

Choose the right model: Select a machine designed for your product type and size.

-

Load correctly: Ensure products are properly positioned to avoid packaging errors and material waste.

-

Use quality packing materials: Sturdy and well-sealed materials protect products during shipping and storage.

-

Monitor performance: Regular checks prevent errors and keep operations running smoothly.

2. Automatic Packaging Machines

Automatic machines offer speed, precision, and consistency—perfect for high-volume operations.

Tips for Optimizing Automatic Machines:

-

Match machine to product: Different products require different settings and machines.

-

Check size limits: Ensure your product fits within the machine’s size capacity.

-

Prepare labels in advance: Most machines require labels to be attached before packaging.

-

Use proper adhesives: Select adhesives suited for your product to avoid clogs and malfunctions.

Key Tips for Choosing the Right Packaging Machine

1. Price and Features

Packaging machines vary widely in price. Compare features carefully—some handle only one type of packaging, while others can process multiple types.

2. Product Compatibility

Ensure the machine is designed for your product’s shape, size, and material. Testing before purchase is highly recommended.

3. Physical Appearance of Products

The type of packaging often depends on the product’s look—printed cardboard boxes, plastic sleeves, or custom cutouts all require different machinery.

4. Material and Freshness Preservation

Especially for food products, choose machines that handle materials preserving freshness and quality. Ensure packaging materials are thin and machine-friendly.

5. Maintenance and Cleanliness

A well-maintained machine ensures consistent performance. Keep the machine clean, follow manufacturer guidelines, and schedule regular inspections.

Conclusion

Selecting the right packaging machine—whether semi-automatic or automatic—can dramatically improve efficiency, reduce waste, and maintain product quality. By considering pricing, compatibility, materials, and maintenance, you can invest in equipment that supports your business growth for years to come.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

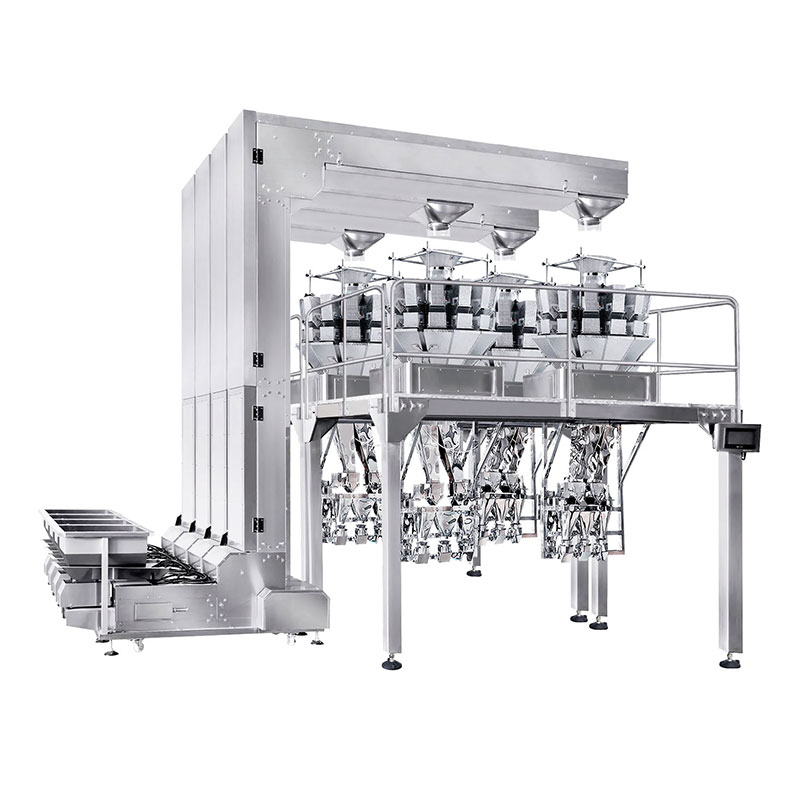

Kenwei's JW-B2 Fully Automatic Twin Packaging Machine boasts 14-head multihead weighing for precise granule and snack food packaging. This high-speed automatic packaging machine offers efficient twin-packaging, maximizing your production output. Ideal for food manufacturers seeking enhanced speed and accuracy.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei