5 Key Factors to Consider When Choosing Packaging Machines for Your Business

Choosing the right packaging machine can boost production efficiency, reduce waste, and cut operating costs. This guide explains the five most important factors to consider—speed, waste handling, cost, training, and packaging variety—helping you make the best investment for your business.

Selecting the right packaging machine is a crucial investment for any business involved in product manufacturing or distribution. The right equipment can increase efficiency, reduce waste, and ensure consistent quality. In this guide, we break down the five most important factors you should consider before making your decision.

1. Speed and Productivity

Speed is one of the most critical factors when selecting a packaging machine.

-

Production Demands: Consider how fast the machine needs to operate to meet your daily or hourly output requirements.

-

Consistency: Determine whether it must maintain a constant speed or adapt to stop-and-start workflows.

-

Adjustability: If you need to regularly change speeds, opt for a machine with easy speed control settings.

2. Waste Management and Disposal

Efficient waste handling can improve machine performance and reduce downtime.

-

Built-in Waste Trays or Containers: Ensure these are easy to empty and maintain.

-

Waste Disposal Systems: Some machines include disposal bags or automated removal features for convenience.

-

Material Compatibility: Confirm the machine can handle your packaging materials without excessive waste.

3. Overhead and Operating Costs

The purchase price is just the beginning—ongoing costs matter just as much.

-

Initial Cost: Choose a machine that fits your budget without compromising quality.

-

Running Costs: Factor in electricity, consumables, and labor.

-

Maintenance: Opt for equipment that’s easy to service and has a manageable maintenance schedule.

4. Staff Training and Ease of Use

The best machine in the world is useless without properly trained operators.

-

Training Availability: Ensure your supplier offers comprehensive training and troubleshooting support.

-

Ease of Operation: Machines with intuitive controls reduce the learning curve.

-

Routine Inspection: Regular checks keep the machine running efficiently and extend its lifespan.

5. Variety of Packaging Options

Different materials require different machinery capabilities.

-

Packaging Types: Paper, plastic, cardboard, and metal cans may require specialized processing.

-

Feature Set: Look for options like automatic feeders, extruders, or advanced sensors for improved accuracy.

-

Scalability: Choose a machine that can adapt as your packaging needs evolve.

Conclusion

Selecting the right industrial packaging equipment involves balancing speed, waste management, operating costs, usability, and packaging flexibility. By considering these five factors, you can invest in a packaging machine that meets your production needs, improves efficiency, and delivers long-term value.

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

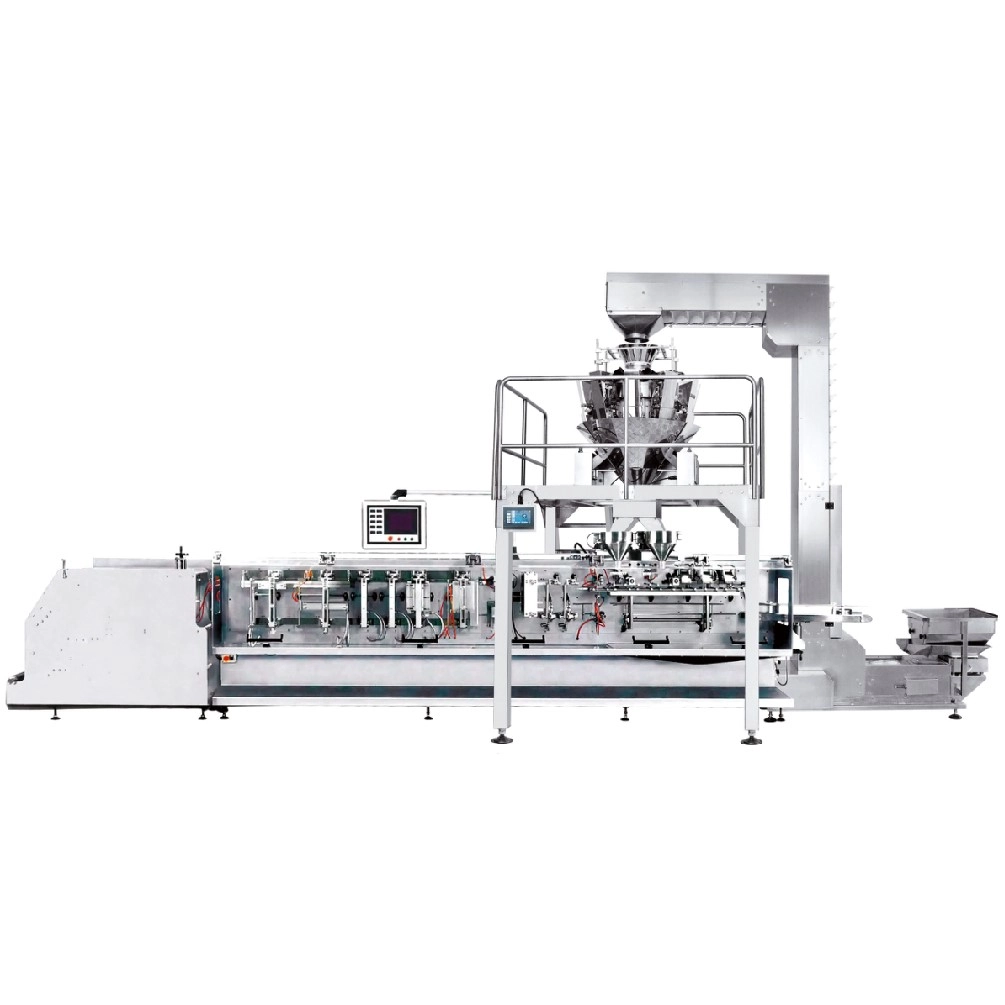

This fully automatic box-type weighing and packing machine is designed for high-precision, high-efficiency packaging of snack foods, puffed products, and granular materials. The system integrates an automatic box dropper, inclined conveyor, multihead weigher, filling and labeling units, ensuring seamless feeding, weighing, filling, printing, and labeling. Ideal for candy, nuts, seeds, jelly, and more. Customizable to meet diverse production needs.

The system consists of a vibrating feeder, a Z-type conveyor, a 14-head combination scale, a material diverter, an automatic cup drop device, a cup mold conveyor, a capping machine and a finished product conveying device. It has high-precision filling capabilities and is suitable for a variety of mold cup combinations. It can realize fully automatic operations of feeding, weighing, filling, bag making, printing and finished product output, and is suitable for a wide range of materials with high production efficiency.

The JW-B7 Economical Linear Weighing and Vertical Packaging Machine is ideal for packaging small granules and powder materials such as sugar, salt, rice, sesame, milk powder, coffee, and seasoning powder. This compact, cost-effective system automates feeding, weighing, filling, and bagging with date printing and output. It reduces labor costs, enhances efficiency, and is perfect for businesses with moderate speed requirements.

The Kenwei Economic Premade Pouch Weighing and Packing Machine JW-B15 offers fully automatic feeding, weighing, filling, date printing, and output. With high accuracy, speed, and space-saving design, it’s ideal for small 3-side or 4-side seal bags. Suitable for granules, slices, irregular shapes like candy, nuts, pet food, and small hardware. A cost-effective solution for precise, efficient packaging.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei