Top 10 multi head weigher Manufacturers and Supplier Brands

- Top 10 Multi Head Weigher Manufacturers and Supplier Brands

- Introduction to Multi Head Weigher Industry and Global Leaders

- 1. Yamato Scale

- 2. Ishida

- 3. Kenwei

- 4. Multiweigh

- 5. Anritsu

- 6. Radwag

- 7. Bilwinco

- 8. PFM Group

- 9. ExaktaPack

- 10. Cabinplant

- Comparison Table: Top 10 Multi Head Weigher Manufacturers

- Conclusion

Top 10 Multi Head Weigher Manufacturers and Supplier Brands

Introduction to Multi Head Weigher Industry and Global Leaders

Multi head weighers have become indispensable in modern food and non-food packaging industries. Designed for high-speed, high-precision weighing, these complex machines are a cornerstone of automated production. As market demand for efficiency, hygiene, and customization grows, choosing a reliable multi head weigher manufacturer is crucial for businesses. In this review, we explore the top 10 global multi head weigher manufacturers and supplier brands, highlighting their unique strengths to help you find your perfect partner in packaging solutions.

1. Yamato Scale

As a global pioneer in weighing technology, Yamato Scale has dominated the multi head weigher industry for decades. Headquartered in Japan, Yamato boasts a robust portfolio of high-speed weighers, perfect for snacks, fresh produce, and frozen foods. Their machines stand out for exceptional precision, advanced hygienic designs, and strong automation integration, offering great ROI for manufacturers worldwide.

2. Ishida

Another Japanese powerhouse, Ishida, is celebrated for its constant innovation in multi head weighing solutions. With a focus on user-friendly operation, hygiene, and groundbreaking weighing technology, Ishida’s weighers are widely used in the food processing industry. Their global service network ensures excellent after-sales support, making them a favored choice for large-scale packaging operations.

3. Kenwei

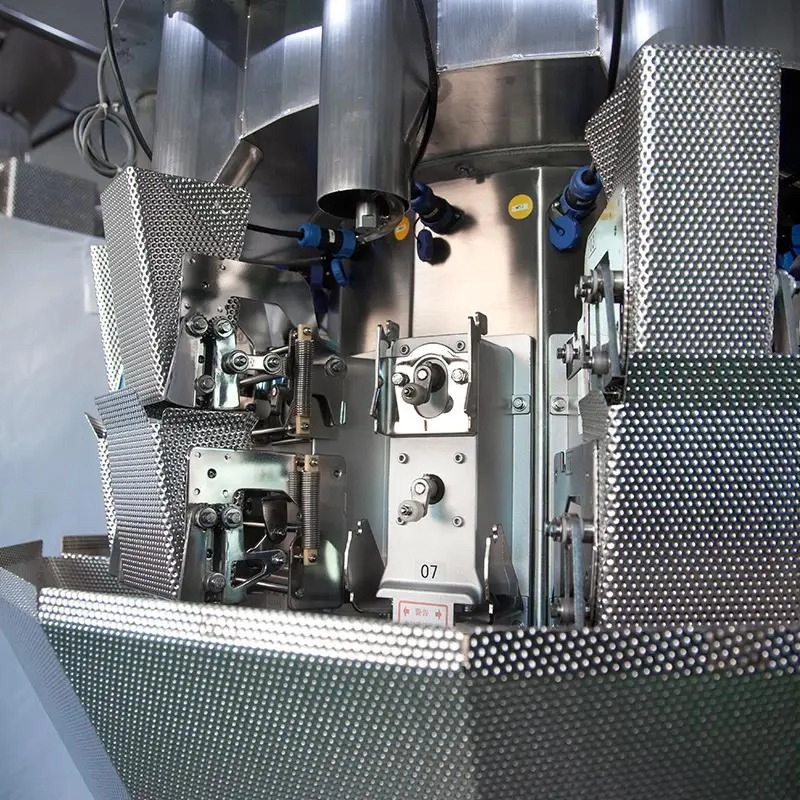

Guangdong Kenwei, located in Fusha High-tech Industrial Park, China, is renowned for its advanced multi head weighers. Committed to development and manufacturing, Kenwei’s products excel in high speed and high precision, with flexible options for custom automated weighing and packaging solutions. Their comprehensive services cover design, installation, technical training, and after-sales support, building a solid brand image in the packaging machinery industry. Kenwei stands out for reliable performance, fast service, and meeting unique customer requirements. Visit Kenwei for more information.

4. Multiweigh

Based in Germany, Multiweigh focuses on developing multi head weighers for even the most challenging products. Their innovative weighing technologies cater to high-mix, low-volume production, providing both precision and flexibility. Multiweigh is recognized for German engineering, energy-saving designs, and rapid changeover features.

5. Anritsu

Anritsu delivers cutting-edge weighing, inspection, and detection equipment from Japan. Its multi head weighers combine high-accuracy weighing with integrated metal detection and advanced control systems. Anritsu stands out in sectors demanding both speed and safety, including fresh produce and protein industries.

6. Radwag

Poland’s Radwag specializes in high-precision weighing instrumentation, offering multi head weighers with advanced digital technology. Known for user-friendly interfaces and durable construction, Radwag’s machines support both food and non-food applications, with strong global distribution and support.

7. Bilwinco

Bilwinco of Denmark brings over six decades of weighers and packaging expertise to the market. They offer tailored multi head weighing solutions with a focus on gentle product handling, food safety, and easy cleaning. Especially popular in fish, meat, and salad packaging, Bilwinco provides both turnkey and modular systems.

8. PFM Group

Italy’s PFM Group offers a complete range of weighing and packaging machinery. Their multi head weighers are engineered for fast, easy integration with bagging and flow-wrapping equipment, making them a one-stop solution for industries ranging from confectionery to cheese.

9. ExaktaPack

USA-based ExaktaPack is recognized for its precision and versatility, producing multi head weighers designed for fast batch changes and minimal downtime. Supporting remote diagnostics and customized software, ExaktaPack meets the needs of North American food processors and beyond.

10. Cabinplant

Cabinplant, located in Denmark, delivers customized multi head weigher systems for demanding food sectors such as fish, seafood, and ready meals. Their strength lies in project engineering, providing full-line automation with an emphasis on gentle handling and sanitation.

Comparison Table: Top 10 Multi Head Weigher Manufacturers

| Brand | Country | Notable Advantages | Industries Served |

|---|---|---|---|

| Yamato Scale | Japan | High precision, hygiene, automation | Snacks, salads, produce, confectionery |

| Ishida | Japan | User-friendly, innovative, global support | Food processing, packaging |

| Kenwei | China | Custom solutions, high speed & precision | Food, hardware, pharmaceuticals |

| Multiweigh | Germany | Adaptable, German engineering | Challenging, mixed lines |

| Anritsu | Japan | Integrated metal detection | Fresh produce, protein |

| Radwag | Poland | Digital technology, sturdy build | Food, industrial, pharma |

| Bilwinco | Denmark | Gentle handling, modularity | Fish, meat, salad |

| PFM Group | Italy | Integrated packaging systems | Dairy, bakery, confectionery |

| ExaktaPack | USA | Precision, software customization | Food, contract packaging |

| Cabinplant | Denmark | Full-line custom automation | Seafood, ready meals |

Conclusion

Selecting the right multi head weigher manufacturer is vital for packaging efficiency, accuracy, and cost-effectiveness. The top brands in this industry—Yamato, Ishida, Kenwei, Multiweigh, Anritsu, Radwag, Bilwinco, PFM Group, ExaktaPack, and Cabinplant—each offer unique advantages, from high-speed custom solutions to advanced integration and impeccable hygiene standards. Evaluate your specific application needs, desired automation level, and after-sales support requirements to make an informed decision. Kenwei, with its commitment to innovation, customer-focused customization, and exemplary service, stands out as a powerful choice for businesses seeking long-term quality and reliability in their weighing and packaging operations.

FAQs

What is a multi head weigher? A multi head weigher is an automated machine that uses multiple weighing heads to quickly and accurately dispense product portions for packaging, improving speed and reducing giveaway.

Why should I invest in a high-quality multi head weigher? High-quality weighers offer greater accuracy, faster production speeds, and less product waste, leading to better productivity and ROI.

Which industry benefits most from multi head weighers? Food sectors (snacks, produce, frozen foods) greatly benefit, but applications extend to hardware, pharmaceuticals, and non-food industries requiring precise packaging.

How do I choose the right supplier? Consider factors like machine precision, ease of cleaning, integration capability, after-sales support, and the supplier’s track record in your industry.

Can Kenwei customize solutions for unique packaging needs? Yes. Kenwei specializes in tailored multi head weighers and complete weighing/packaging automation to meet specific customer requirements.

Multihead Weigher Working Principle Explained

Troubleshooting Common Combination Weigher Problems

What are the application scenarios of single head weigher?

Top features to evaluate in a 14 head multihead weigher buying guide

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About After Sales Support

How about the after-sales service?

Warranty :2 years

Multi Head Combination Weigher with Intelligent Feeding Control

Kenwei Multi Head Combination Weigher with Intelligent Feeding Control ensures high-speed, precise, and efficient weighing. Ideal for food and non-food industries, this advanced combination weigher boosts productivity and accuracy for all your multihead weigher needs.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei