Advanced Packaging Solutions Driving the Growth of the Frozen Food Industry

The frozen food industry is expanding rapidly, requiring innovative packaging technologies to maintain quality and safety. Guangdong Kenwei’s customized multihead weighers and automated packing systems provide efficient, hygienic, and reliable solutions designed specifically for the challenges of frozen food production and packaging.

The global economy’s development, changing lifestyles, and evolving dietary habits have accelerated the growth of the frozen food industry, with an annual increase rate of approximately 25%. Per capita annual consumption of frozen food is nearing 10 kilograms. As frozen food becomes more popular, packaging technologies face increasing demands for quality preservation, safety, and convenience.

The primary function of frozen food packaging is to preserve product quality throughout production, transportation, and sales, prevent bacterial contamination, and ensure user-friendly consumption. Currently, flexible packaging based on plastic films is widely used in the frozen food sector. Corresponding packaging equipment includes mature solutions such as multihead weighers, vertical form fill seal (VFFS) machines, and rotary bag packaging machines.

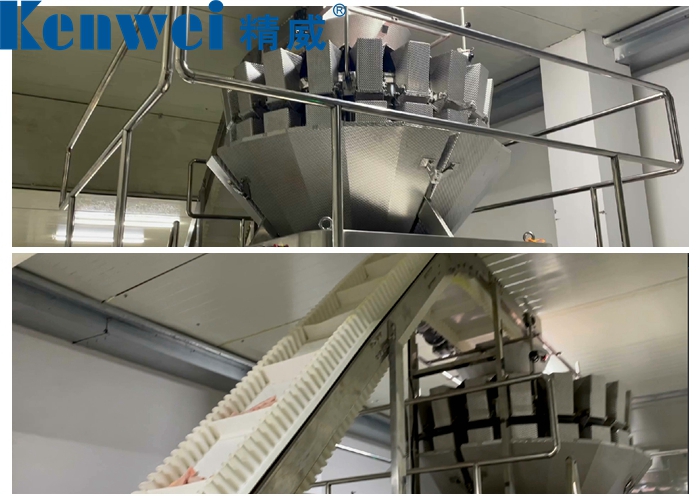

Case Study: Efficient Frozen Duck Wings Packaging System by Guangdong Kenwei

Guangdong Kenwei’s customized packaging solution for frozen duck wings demonstrates how automated food packing equipment upgrades drive efficiency and convenience in the frozen food industry.

The system centers around Kenwei’s intelligent, high-speed 20-head computerized multihead weigher, paired with a rotary bag-feeding packaging machine that performs automatic bagging and heat-sealing. This setup supports various plastic film bag types per customer requirements. Additionally, a check weigher is integrated downstream to ensure quantitative accuracy and food packaging safety standards, maximizing production efficiency.

Features and Advantages

-

Multi-functionality: Suitable for mixing and high-speed weighing of multiple or single granular and block materials including food, hardware, and plastic parts.

-

Customized hopper design: Patterned hoppers with high-grade waterproof internal structures adapt to harsh production environments like cold, humid workshops common in frozen food processing.

-

Robust construction: IP65-rated cabinet and dimpled food-contact plates made from stainless steel enhance durability and hygiene.

-

Humidity protection: Built-in air pressure systems protect electronic components from moisture damage.

-

Precision control: Independent main vibration machines adjust feeding thickness for different materials, improving weighing accuracy.

-

Structural rigidity: Integrated chassis and middle seat strengthen machine rigidity for stable, precise weighing.

[Video Link: https://www.kenweigroup.com/multihead-weigher-for-frozen-food-weighing.html]

Industry Outlook

Frozen food packaging plays a vital role in ensuring the hygiene and safety of frozen products. This drives continuous innovation in packaging and inspection equipment. Guangdong Kenwei, a leader in intelligent weighing and packaging, has devoted 16 years to innovating cost-effective, efficient multihead weighers, linear weighers, check weighers, and comprehensive packaging solutions. These advances support food businesses in maintaining steady growth and meeting evolving market demands.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei