The Rapid Growth and Technological Advancement of China’s Food Packaging Machinery Industry

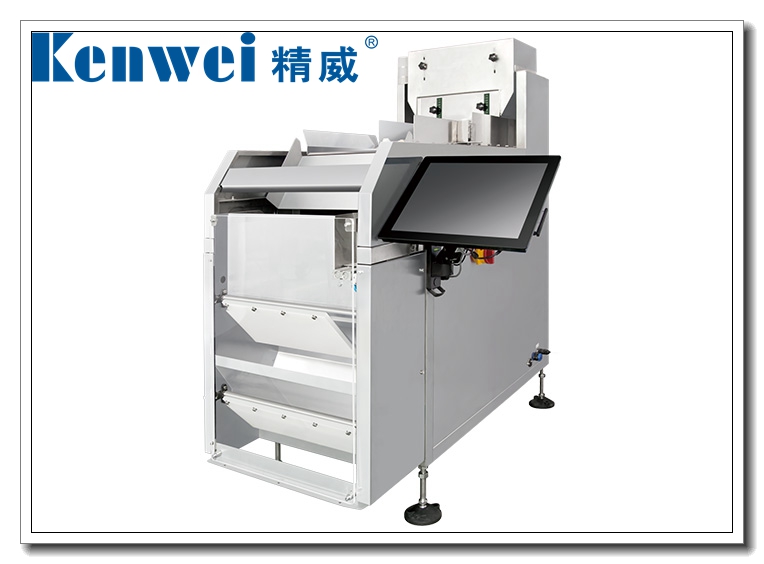

China’s food packaging machinery sector is among the fastest-growing industries, fueled by rapid food processing development and technology integration. Guangdong Kenwei champions innovation by providing advanced automated weighing and packaging equipment, supporting the modernization of domestic food packaging solutions.

In recent years, China’s food packaging machinery manufacturing industry has emerged as one of the fastest-growing and most dynamic pillar industries within the national economy. It plays a crucial role in supplying technical equipment for the expanding food industry. Alongside increased production scale, Chinese food packaging machinery is rapidly integrating optical and mechanical automation technologies. This progress is especially evident in filling machines, packaging equipment, and packaging material production devices, including key weighing equipment like multihead weighers, linear weighers, and check weighers.

Despite the industry's rapid growth, domestic exports represent less than 5% of total output value, while imports nearly match total domestic production. This gap highlights significant demand for domestic packaging machinery and the need to complement local products with imported equipment. Although domestic enterprises still lag behind foreign brands in some areas, China’s food packaging machinery industry is steadily advancing and demonstrating promising development trends.

Food Industry as a Growth Driver

Since its inception in the early 1980s, China’s food packaging machinery industry has rapidly expanded. Currently, there are nearly 6,000 manufacturers, with about 15% of enterprises exiting or shifting production annually, matched by a similar number of new entrants. This dynamic reflects intense competition alongside abundant opportunities and strong growth potential.

Among these companies, only a dozen report annual sales exceeding 100 million yuan, and about 50 companies generate over 30 million yuan annually. These 50 firms account for approximately 75% of industry exports, with leading enterprises such as Guangdong Kenwei and Highdream holding significant technological and production advantages in the market.

With the strategic focus on economic development and deep processing of agricultural products, China’s food processing sector grows at an average annual rate of 13-14%. This rapid expansion creates vast opportunities for the packaging industry, especially in sales packaging and transportation packaging, fueling the accelerated development of food packaging machinery manufacturing.

High-End Technology Drives Product Upgrades

He Nanzhi, Executive Vice Chairman of the China Food and Packaging Machinery Industry Association, notes that food inspection technologies have advanced beyond simple impurity detection on production lines. The sector increasingly embraces precise quantitative inspection and innovative solutions such as high-precision metal detectors and machine vision.

For example, Guangdong Kenwei’s dual-channel 303 visual particle counting machine employs imported high-speed linear CCD sensors and high-definition lenses, capable of detecting particles as small as 0.3mm at speeds up to 16,000 pieces per minute with minimal error. Such innovations enable rapid and accurate counting of electronic components, tablets, and food products.

Furthermore, digital wireless sensor networks and food information collection systems enhance transparency in food production, transportation, and storage, helping alleviate consumer concerns about food safety.

Challenges and Future Outlook

Although domestic companies are gradually adopting automation technologies, progress is limited by market acceptance and the reliance on imported mature technologies. To overcome these challenges, China’s packaging industry must balance technology introduction with independent innovation, tailoring equipment to meet domestic market needs effectively.

Guangdong Kenwei embraces the principles of “stability as the foundation,” “professional manufacturing,” “excellent quality,” and “integrity management.” By integrating advanced automation with market demands, Kenwei delivers high-quality, efficient automatic weighing and packaging equipment to the domestic food industry, helping businesses overcome packaging challenges and pursue sustainable, win-win growth.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei