The Evolution of Digital Packaging: Integrating IoT and Intelligent Automation

Digital packaging is evolving rapidly with IoT, big data, and intelligent automation driving industry transformation. Guangdong Kenwei’s cloud-based interconnection systems and servo-controlled manipulators offer flexible, efficient packaging solutions that enhance traceability, remote monitoring, and production automation in today’s smart factories.

With the rapid development of mobile Internet and digital technologies, the packaging industry is undergoing a significant transformation. The integration of the Internet of Things (IoT) and big data is accelerating the shift from traditional packaging to advanced digital packaging, meeting growing consumer demands for smarter and more connected products.

Generations of Digital Packaging

-

First Generation: Focused on basic functionalities such as anti-counterfeiting and traceability. Products employed simple QR codes to provide consumers with easy access to product information.

-

Second Generation: Integrated printed electronics, RFID, and explicit technology to enable smarter applications, adding more interactive and data-driven features to packaging.

-

Third Generation: Utilizes cutting-edge technologies like NFC, blockchain, AR, IoT, and Internet technology, enabling seamless integration between packaging production lines and enterprise systems (ERP). This facilitates remote maintenance, real-time data evaluation, and intelligent control.

Guangdong Kenwei’s “Cloud Configuration” Intelligent Interconnection System

Leading the digital packaging revolution, Guangdong Kenwei has developed the “Cloud Configuration” system, featuring:

-

A modular, highly integrated design utilizing CAN bus technology and the Modbus industrial communication protocol.

-

IoT-enabled remote monitoring and intelligent control via multiple devices including computers, smartphones, and tablets.

-

Automated data collection and production line supervision, combining advanced weighing packaging technologies with intelligent control systems for superior operational efficiency.

Intelligent Control Systems for Packaging

-

Extranet Intelligent Control: Uses Ethernet, GPRS, WiFi, 3G/4G networks combined with IoT-capable touch screens to enable efficient equipment monitoring, data analysis, and management.

-

Intranet Intelligent Control: Adds a network module to device mainboards, seamlessly connecting with SCADA systems and integrating with ERP and MES software. This builds fully automated smart factories, improving equipment automation, production efficiency, and profitability.

Flexibility Trends in Digital Packaging Equipment

Increasing demands for equipment flexibility have led to:

-

More servo motors replacing traditional PLC logic functions.

-

Integrated motion and logical control solutions that unify programming languages and physical/logical interfaces for easier customization and adaptability.

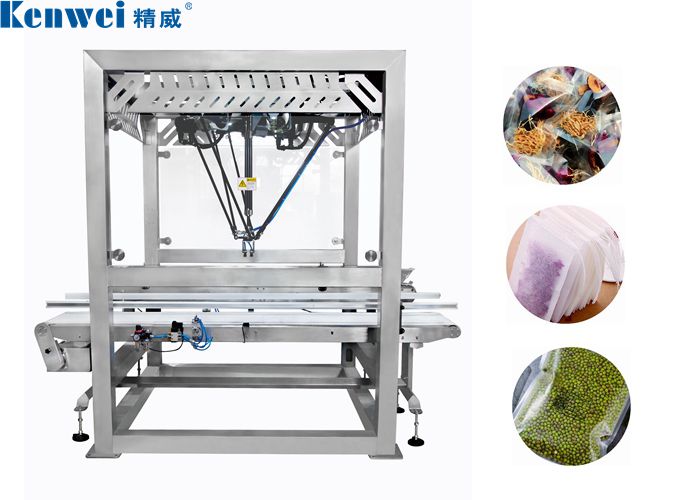

Application Spotlight: Guangdong Kenwei’s Four-Axis Parallel Manipulator

Utilizing a servo motor control system paired with visual detection devices, this manipulator:

-

Performs fast, precise automatic grabbing, box loading, and intelligent palletizing at the top of production lines.

-

Offers superior flexibility compared to horizontal machines, adapting easily to various products with interchangeable vacuum fixtures.

-

Supports complex packaging needs in industries such as pharmaceuticals (e.g., blister packs, medicine bottles, instructions, spoons) and confectionery (accurate placement of assorted chocolates).

Digital packaging powered by IoT and automation is revolutionizing the packaging industry. Guangdong Kenwei’s innovative systems enable enterprises to embrace intelligent manufacturing, enhancing product traceability, operational efficiency, and market competitiveness in an increasingly digital world.

About After Sales Support

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei