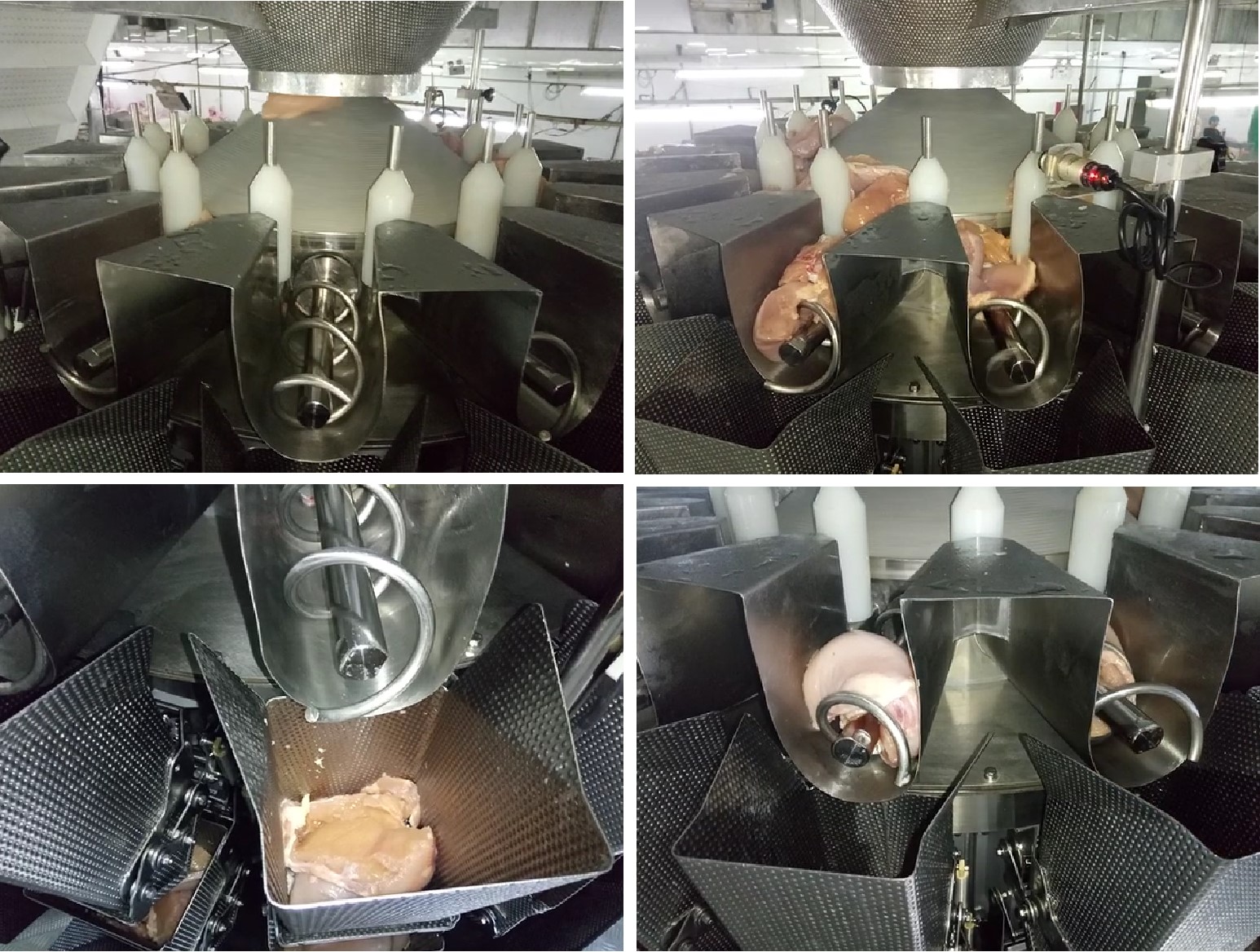

Screw Feeder Multihead Weigher for Sticky Protein Applications

Kenwei’s Screw Feeder Multihead Weigher is designed for high-precision weighing of sticky and bulky protein products such as chicken, pork, duck, and fish. Featuring advanced screw feeding technology, it ensures accuracy, efficiency, hygiene, and reliability for modern food processing facilities.

High-Performance Screw Feeder Multihead Weigher

Kenwei’s Screw Feeder Weigher is a high-performance weighing solution built for precision, efficiency, and consistency in food production. It is specifically designed for sticky and bulky protein applications such as fresh chicken, pork, duck, and fish. By automating portioning, it ensures accurate dosing and reliable operation across demanding industrial environments.

Innovative Screw Feeding Technology

Unlike traditional vibratory feeding systems, the Screw Feeder Multihead Weigher uses rotating screw technology to control product flow. This innovation eliminates the inconsistencies caused by vibration, ensuring smooth handling of sticky or irregularly shaped proteins. As a result, food processors benefit from improved accuracy, reduced product waste, and higher efficiency.

Versatility for Protein Applications

The Screw Feeder Weigher stands out for its ability to manage products that are difficult to handle with standard multihead weighers. Whether weighing sticky chicken pieces, bulky pork cuts, or delicate fish fillets, the system delivers precise portioning without product damage. This versatility makes it a valuable asset for food manufacturers aiming to streamline their processes and maintain consistent quality.

Hygienic Design and Easy Maintenance

In addition to its weighing performance, Kenwei’s Screw Feeder Weigher is designed with food safety and hygiene as top priorities. The equipment features sanitary construction and allows for easy disassembly, making cleaning and maintenance quick and efficient. This minimizes downtime and ensures compliance with food industry standards.

A Complete Solution for Protein Weighing

Overall, the Screw Feeder Multihead Weigher offers a reliable and efficient solution for food manufacturers handling sticky or bulky protein products. With its advanced screw feeding technology, high-speed performance, and hygienic design, it helps businesses optimize production, reduce waste, and deliver high-quality products to their customers.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei