Screw Feeding Noodle Weigher: Precision Packaging Solution for Noodles and Sticky Materials

The screw feeding noodle weigher is designed for precise and efficient portioning of noodles and other sticky, slender materials. With advanced screw feeding technology, it ensures accuracy, consistency, and hygiene in noodle packaging, making it ideal for modern food manufacturing facilities.

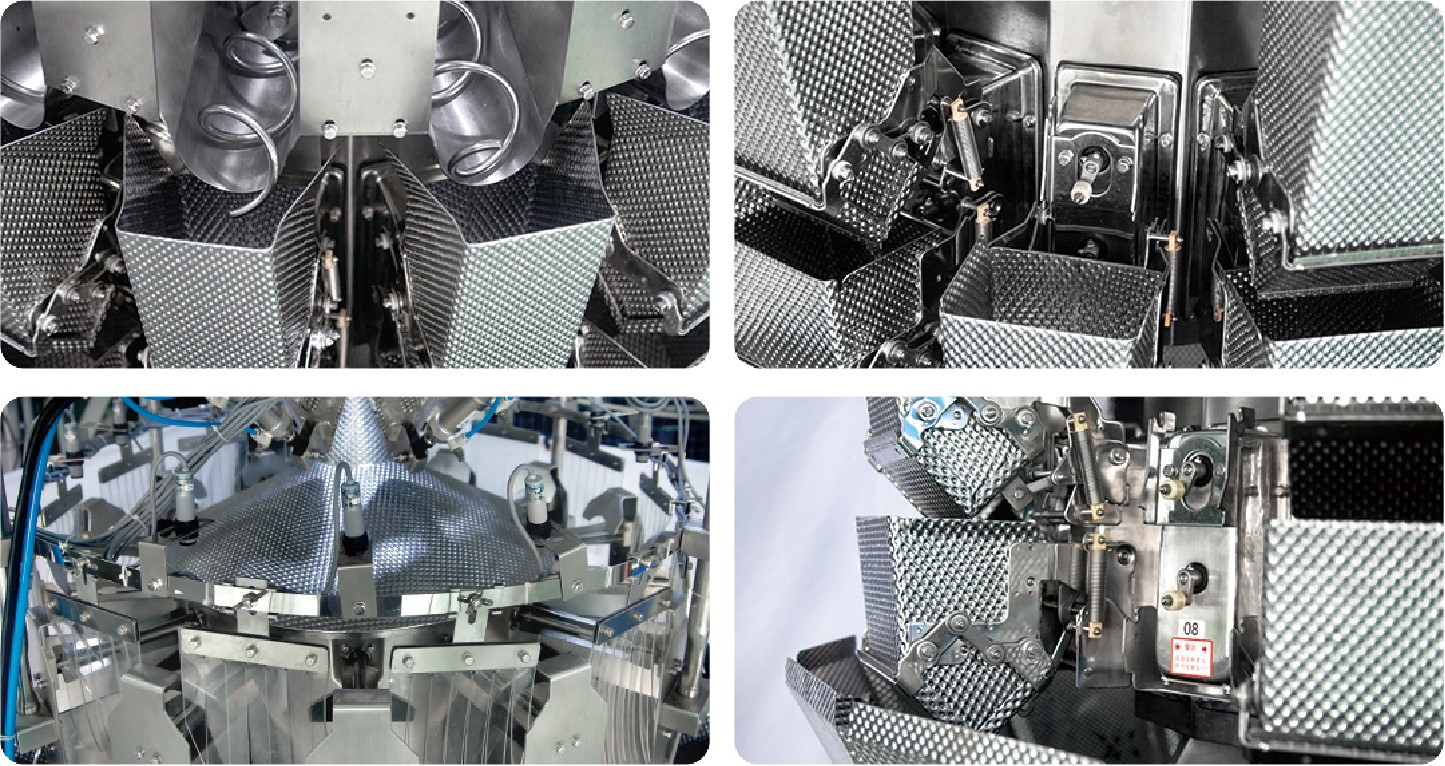

Advanced Screw Feeding Technology for Noodle Packaging

The screw feeding noodle weigher is engineered to deliver accurate and consistent portioning for noodle packaging. It is suitable for weighing a wide range of sticky and slender materials such as noodles, rice flour, rice noodles, kelp, and wakame. By using a screw feeding mechanism, the machine precisely controls product flow, ensuring every package contains the correct portion.

How the Screw Feeding Noodle Weigher Works

The system operates with a rotating screw that conveys noodles from the hopper to the weighing hopper. The screw’s speed and rotation can be adjusted to regulate flow, ensuring precise measurements. Once in the weighing hopper, the noodles are measured accurately, and the cycle repeats for each package. This guarantees consistent results in every packaging cycle.

Key Benefits and Applications

-

Versatility: Handles different noodle types and sizes, from long and thin to short and thick, without damage or breakage.

-

Accuracy: Ensures precise portioning, improving product quality and customer satisfaction.

-

Efficiency: Automates weighing to reduce labor costs, minimize human error, and maintain hygiene.

-

Easy Maintenance: Built with accessible components for cleaning and servicing, ensuring durability and long-term performance.

-

Why Choose a Screw Feeding Noodle Weigher?

For noodle manufacturers, consistency and efficiency are critical. This noodle weighing machine not only improves portioning accuracy but also boosts production speed while maintaining hygiene. Its adaptability and user-friendly design make it an essential tool for food packaging lines.

Conclusion:

The screw feeding noodle weigher combines precision, efficiency, and versatility, making it the perfect solution for modern noodle production. By automating portioning and ensuring accuracy, it helps manufacturers maintain high standards in noodle packaging while reducing costs and improving productivity.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei