How Linear Weighers Boost Packaging Line Efficiency: Practical Benefits and ROI

- How Linear Weighers Boost Packaging Line Efficiency

- Introduction: Why packaging lines need smarter weighing

- What is a linear weigher and where it fits in a line

- Benefit 1 — Faster cycle times with predictable throughput

- Benefit 2 — Improved accuracy and reduced giveaway

- Benefit 3 — Gentle handling for fragile products

- Benefit 4 — Compact footprint and easier line integration

- Benefit 5 — Faster changeovers and flexible recipes

- Benefit 6 — Data, control, and quality assurance

- How linear weighers compare to multihead weighers and check weighers

- Real-world ROI: How efficiency translates to savings

- Installation, serviceability, and total cost of ownership

- Case example: Typical improvements after installing a linear weigher

- Checklist: Is a linear weigher right for your line?

- Conclusion: Strategic gains beyond speed

- About Kenwei

- Frequently Asked Questions

How Linear Weighers Boost Packaging Line Efficiency

Introduction: Why packaging lines need smarter weighing

Today’s consumer goods and food-packaging lines compete on speed, accuracy, and waste reduction. One key technology that directly affects these metrics is the linear weigher. In this article we explain how linear weighers boost packaging line efficiency, compare them to other weighing solutions, and show how manufacturers like Kenwei deliver turnkey systems that accelerate throughput and improve yield.

What is a linear weigher and where it fits in a line

A linear weigher (sometimes called a linear combination weigher) aligns multiple weighing channels in a single row. Products are dosed into each channel, weights are summed or combined, and the right combination is discharged into the packer. Linear weighers are typically used for free-flowing, semi-free-flowing, and some fragile products where a linear feed and gentle handling are required. They are especially useful when you need high repeatable speeds, precise portion control, and compact integration.

Benefit 1 — Faster cycle times with predictable throughput

Linear weighers boost packaging line efficiency by delivering consistent, predictable cycle times. Because multiple channels dose simultaneously and combinations are calculated rapidly, linear systems can achieve high portions-per-minute rates without long interruptions caused by single-channel filling. Typical throughputs depend on product characteristics and portion size; in practice, linear weighers often support several hundred to over a thousand portions per hour for many products. That predictable throughput allows downstream equipment—fillers, sealers, and case packers—to run at optimal speeds, reducing bottlenecks.

Benefit 2 — Improved accuracy and reduced giveaway

Accuracy is a direct driver of packaging costs. Linear weighers use precise load cells and stable feeding to minimize variation. Reduced weight variance cuts giveaway (overfilling) and lowers product cost per package. Depending on product and target weight, improvements can reduce giveaway by a measurable percentage, leading to significant annual savings on high-volume lines. Many linear weighers can maintain accuracy within a fraction of a gram for small portions and within a consistent margin for larger portions.

Benefit 3 — Gentle handling for fragile products

Compared to some high-impact filling systems, linear weighers can offer gentler product handling. The linear flow and controlled discharge reduce product breakage for items like chips, biscuits, or delicate snacks. Lower breakage increases sellable yield and reduces rework and waste, which further improves overall equipment effectiveness (OEE).

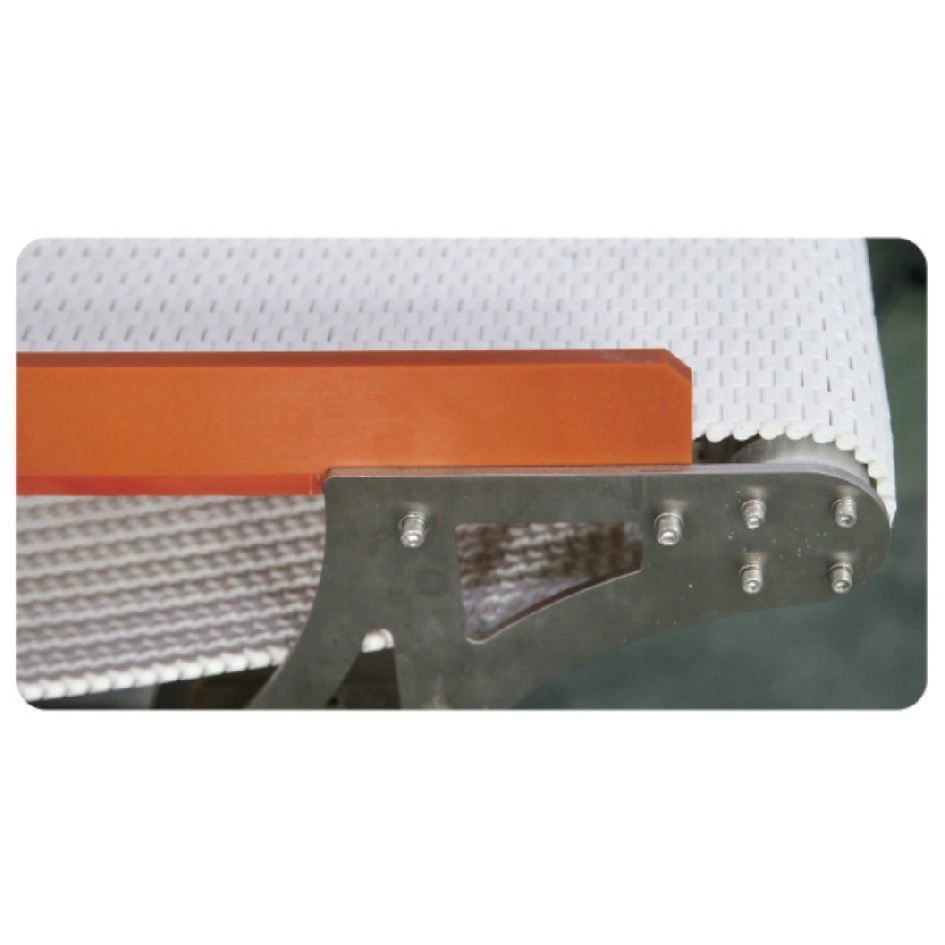

Benefit 4 — Compact footprint and easier line integration

Linear weighers typically have a compact, modular footprint: channels are arranged in a straight line that aligns naturally with vertical form-fill-seal (VFFS) machines or horizontal flow-wrapping lines. This compactness simplifies conveyor and chuting design, shortens product travel distances, and reduces the need for extensive line reconfiguration. For factories where floor space is at a High Quality, a smaller footprint can lower installation costs and accelerate commissioning.

Benefit 5 — Faster changeovers and flexible recipes

Modern linear weighers are designed with quick-change parts and recipe-driven controls. Tool-less chutes, adjustable infeed gates, and recipe storage mean that switching portion sizes or SKUs can be a matter of minutes instead of hours. Faster changeovers increase productive time and support higher SKU diversity without sacrificing efficiency—critical for contract packers and manufacturers facing frequent line changes.

Benefit 6 — Data, control, and quality assurance

Integrated control systems and HMI interfaces give operators real-time performance data (throughput, average weight, standard deviation). This data supports immediate corrective actions and longer-term process optimization. When integrated with factory MES or SPC systems, linear weighers contribute to traceability, compliance, and continuous improvement—key elements of Google’s EEAT-style product content that demonstrates expertise and reliability.

How linear weighers compare to multihead weighers and check weighers

Choosing the right weigher depends on product, speed, and accuracy needs. Below is a practical comparison highlighting when a linear weigher is the best option.

| Feature | Linear Weigher | Multihead Weigher | Checkweigher |

|---|---|---|---|

| Best for | Free-flowing to semi-free products; gentle handling; compact lines | High-speed, high-precision portioning for small to medium items (snacks, nuts) | Final weight verification after packaging |

| Throughput | Hundreds to 1,000+ portions/hour (product-dependent) | Very high—can exceed 1,000 portions/min for some applications | Depends on conveyor speed; used for verification not primary filling |

| Gentle handling | High | Variable—can be more aggressive | Not applicable |

| Footprint | Compact; linear layout | Larger, circular footprint | Small, inline |

| Typical use | Single-portion dosing into bags, trays | Precise multi-piece portions | Weight compliance and rejection |

Real-world ROI: How efficiency translates to savings

ROI on a linear weigher is driven by reduced giveaway, higher throughput, and lower labor and rework costs. Example (illustrative): a mid-volume snack line running 8,000 packs/day with average giveaway of 1.5 g saved by improved accuracy at $4/kg product cost could save thousands of dollars annually. Add labor savings from faster changeovers and decreased downtime and the payback period for many installations is often 12–36 months depending on line parameters. Kenwei supports customers with application-specific ROI modeling to show precise savings for their SKUs.

Installation, serviceability, and total cost of ownership

Efficient systems are only as good as their uptime. Kenwei provides one-stop automated weighing and packaging solutions, including commissioning, technical training, and after-sales service from Guangdong. Key TCO considerations: preventive maintenance intervals, ease of spare-part replacement, and local service responsiveness. Choosing a supplier with full lifecycle support shortens downtime and protects efficiency gains.

Case example: Typical improvements after installing a linear weigher

Common measurable improvements after a linear weigher installation include: 10–30% reduced giveaway, 15–40% higher effective throughput through fewer stoppages, and 20–50% faster product changeovers. Actual figures depend on product type, existing equipment, and process discipline. Kenwei’s automated systems are engineered to deliver these practical performance gains while meeting hygiene and food-safety standards.

Checklist: Is a linear weigher right for your line?

Ask these questions to evaluate fit: What is the product flow (free-flowing, fragile, sticky)? What target throughput and accuracy are required? How often do you change SKUs? What is the available footprint? If you need compact layout, gentle handling, and accurate portion control with flexible recipes, a linear weigher is likely a strong candidate.

Conclusion: Strategic gains beyond speed

Linear weighers boost packaging line efficiency not only by increasing speed but by improving accuracy, reducing waste, simplifying integration, and enabling faster changeovers. When combined with a supplier that offers design, installation, and lifecycle service—such as Kenwei—manufacturers realize measurable improvements in OEE, lower total cost of ownership, and faster payback. Selecting the right machine for your product profile and working with experienced vendors are essential steps to unlocking the full benefits of linear weighing technology.

About Kenwei

Kenwei is a manufacturer of multi-head weighers and a provider of linear weighers, metal detectors, and check weighers located in Fusha High-tech Industrial Park, Zhongshan, Guangdong Province. The company offers automated weighing and packaging systems with capabilities in design, manufacturing, installation, training, and after-sales service. Visit https://www.kenweigroup.com/ to learn how Kenwei can help optimize your packaging line.

Frequently Asked Questions

What are the primary advantages of linear weighers over other weighing methods?Linear weighers offer predictable throughput, compact footprints, gentle product handling, and easier integration with downstream equipment—making them ideal for many packaging lines that require consistent portioning and quick changeovers.

How much can I expect to reduce product giveaway with a linear weigher?Reduction depends on current process accuracy and product variability. Many users see 10–30% less giveaway after optimizing a dosing system with a precise linear weigher; Kenwei can model expected savings for your SKUs.

Are linear weighers suitable for fragile products like chips and biscuits?Yes. Linear weighers provide gentler handling than some high-impact systems, reducing breakage and increasing sellable yield for fragile products.

How long does it take to switch SKUs or portion sizes?Modern linear weighers have recipe-based controls and quick-change parts; typical changeovers can be reduced to minutes rather than hours depending on the level of tooling change required.

What maintenance is required to keep a linear weigher running efficiently?Routine preventive maintenance includes load-cell checks, cleaning of chutes and hoppers, inspection of sensors and drives, and software updates. Kenwei provides training and after-sales support to ensure long-term performance.

How do I choose between a linear weigher and a multihead weigher?Choose based on product characteristics and target speed. Multihead weighers excel at very high-speed multi-piece portions and fine precision for small items; linear weighers are preferred when linear flow, compact layout, and gentle handling matter. Kenwei’s specialists can evaluate your product and line to recommend the best solution.

Top 10 checkweigher scale Manufacturers and Supplier Brands

ROI of Investing in Good Metal Detectors for Food Safety

Where to Buy combination weigher

Top 10 Food Grain Packing Machine Features to Look For

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei