The latest trends for combination weigher machine

- The Latest Trends for Combination Weigher Machine in 2025

- Rising Automation in Combination Weigher Machine Technology

- IoT Connectivity Transforming Combination Weigher Machines

- Focus on Sustainability with Combination Weigher Machines

- Enhanced Precision and Speed in Combination Weigher Machines

- Growing Applications Across Diverse Industries

- Customization and Flexibility in Combination Weigher Machine Designs

- Regulatory Compliance and Quality Assurance

- Conclusion: Staying Ahead with Combination Weigher Machine Innovations

The Latest Trends for Combination Weigher Machine in 2025

As the global demand for efficient and accurate weighing solutions grows, the combination weigher machine industry is evolving at a remarkable pace. At Kenwei, a leading manufacturer of multi-head weighers, we are at the forefront of these advancements, providing high-speed, high-precision machines to meet diverse industry needs. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei specializes in metal detectors, multi-head weighers, linear weighers, and check weighers. Our commitment to innovation and one-stop automated weighing and packaging solutions ensures that we meet our customers’ customization requirements with excellence. In this blog, we’ll dive into the latest trends shaping the combination weigher machine sector in 2025, helping businesses stay ahead in a competitive market.

Rising Automation in Combination Weigher Machine Technology

Automation continues to be a game-changer in the world of combination weigher machines. With industries like food processing and pharmaceuticals demanding faster production lines, automated weighers are becoming essential. These machines, equipped with intelligent systems, can handle complex tasks like material distribution and dynamic weighing with minimal human intervention. At Kenwei, our multi-head weighers integrate seamlessly into automated production lines, achieving precision up to ±0.1g through the combination of 8 to 32 independent weighing units. This trend not only boosts productivity but also reduces labor costs, making it a top choice for businesses looking to scale operations.

IoT Connectivity Transforming Combination Weigher Machines

The integration of Internet of Things (IoT) technology is revolutionizing how combination weigher machines operate. IoT-enabled weighers allow real-time monitoring, data collection, and remote troubleshooting, ensuring optimal performance. This connectivity helps manufacturers track machine efficiency, predict maintenance needs, and minimize downtime. At Kenwei, we are incorporating IoT features into our systems to provide smarter solutions for our clients. As industries move towards smart factories, adopting IoT in combination weighers is no longer an option but a necessity for staying competitive in 2025.

Focus on Sustainability with Combination Weigher Machines

Sustainability is a growing concern across industries, and the combination weigher machine sector is no exception. Manufacturers are now designing machines that reduce material waste and energy consumption. For instance, modern weighers optimize packaging processes to use fewer resources while maintaining accuracy. At Kenwei, we are committed to developing eco-friendly solutions that align with global sustainability goals. By choosing energy-efficient combination weighers, companies can lower their carbon footprint while meeting regulatory standards, making this a critical trend for environmentally conscious businesses.

Enhanced Precision and Speed in Combination Weigher Machines

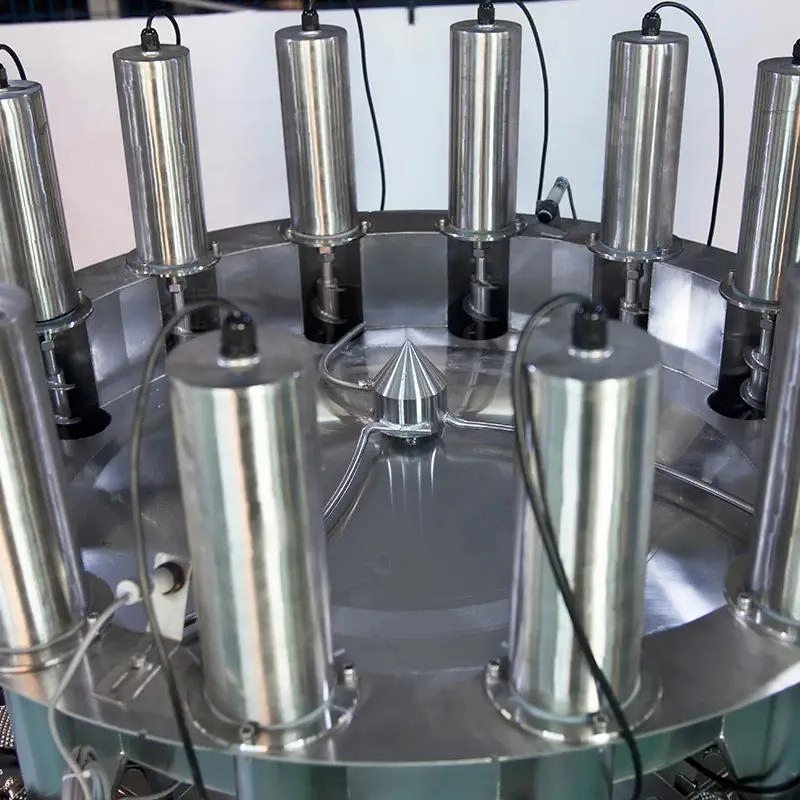

Precision and speed remain the cornerstone of any high-quality combination weigher machine. With advancements in sensor technology and design, modern weighers can handle a wide range of products—from granular items to delicate goods—with unparalleled accuracy. Kenwei’s multi-head weighers, for example, use a three-layer architecture (vibrating feeding tray, weighing hopper group, and collection hopper) to ensure dynamic measurement and high-speed output. This trend is particularly beneficial for industries like food and medicine, where even minor deviations can impact product quality and safety.

Growing Applications Across Diverse Industries

The versatility of combination weigher machines is driving their adoption across various sectors. Beyond traditional food packaging, these machines are now widely used in pharmaceuticals, chemicals, and even hardware industries for precise sorting and weighing. At Kenwei, we’ve seen increased demand for customized solutions tailored to specific industry needs. This trend highlights the importance of adaptable equipment, as businesses seek combination weighers that can handle unique products and packaging requirements without compromising efficiency.

Customization and Flexibility in Combination Weigher Machine Designs

One-size-fits-all solutions are a thing of the past. Today, businesses demand combination weigher machines that offer flexibility and customization. Whether it’s adjusting the number of weighing heads or integrating with specific packaging systems, manufacturers like Kenwei are prioritizing bespoke designs. Our one-stop automated weighing and packaging solutions cater to individual client specifications, ensuring seamless integration into existing workflows. This trend towards tailored solutions is empowering companies to address niche market demands and improve overall productivity.

Regulatory Compliance and Quality Assurance

As industries face stricter regulations, combination weigher machines must meet higher standards for accuracy and safety. Regulatory bodies in sectors like food and pharmaceuticals require precise measurements to ensure consumer safety. Modern weighers are now equipped with features that support compliance, such as detailed data logging and traceability. Kenwei’s machines are designed to adhere to international standards, helping our clients maintain quality assurance while avoiding costly penalties. Staying compliant with regulations is a key trend shaping the industry in 2025.

Conclusion: Staying Ahead with Combination Weigher Machine Innovations

The combination weigher machine industry is undergoing a transformative phase in 2025, driven by automation, IoT connectivity, sustainability, and customization. At Kenwei, we are proud to lead the charge by offering cutting-edge multi-head weighers that deliver high speed, precision, and tailored solutions. Located in Guangdong Province, our company combines comprehensive design, manufacturing, and after-sales service capabilities to support businesses worldwide. As we strive to become the world’s leading weighing and packaging machine manufacturer, we invite you to explore our innovative solutions at https://www.kenweigroup.com/. Embrace these trends today to enhance your production efficiency and stay ahead in a dynamic market.

Frequently Asked Questions (FAQs) About Combination Weigher Machines

1. What is a combination weigher machine?

A combination weigher machine, also known as a multi-head weigher, is a device used in industrial settings to weigh and sort products with high precision. It combines multiple weighing units to achieve accurate measurements, ideal for industries like food and pharmaceuticals.

2. How does a combination weigher machine improve efficiency?

These machines automate the weighing process, reducing manual labor and increasing speed. With advanced technology, they minimize errors and ensure consistent output, saving time and resources for businesses.

3. What industries benefit from using combination weigher machines?

Combination weighers are widely used in food processing, pharmaceuticals, chemicals, and hardware sectors. They handle a variety of products, making them versatile for different industrial applications.

4. Why choose Kenwei for combination weigher machines?

Kenwei offers high-speed, high-precision multi-head weighers with customizable options. Based in Guangdong, we provide one-stop solutions, from design to after-sales service, ensuring customer satisfaction and operational excellence.

5. How do modern trends like IoT impact combination weigher machines?

IoT integration allows for real-time monitoring and data analysis, helping businesses optimize performance and reduce downtime. It’s a key trend making combination weighers smarter and more efficient in 2025.

Food Grain Packing Machine vs. Traditional Packaging Methods: Which Is Right for Your Business?

Throughput Comparison: Multihead Weigher Options for Pickles

Hygienic Design Features in Food Metal Detectors

ROI Analysis: Semi Automatic Powder Packing Machines for SMEs

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei