Kenwei Production Lines: Automated Weighing & Packaging Solutions

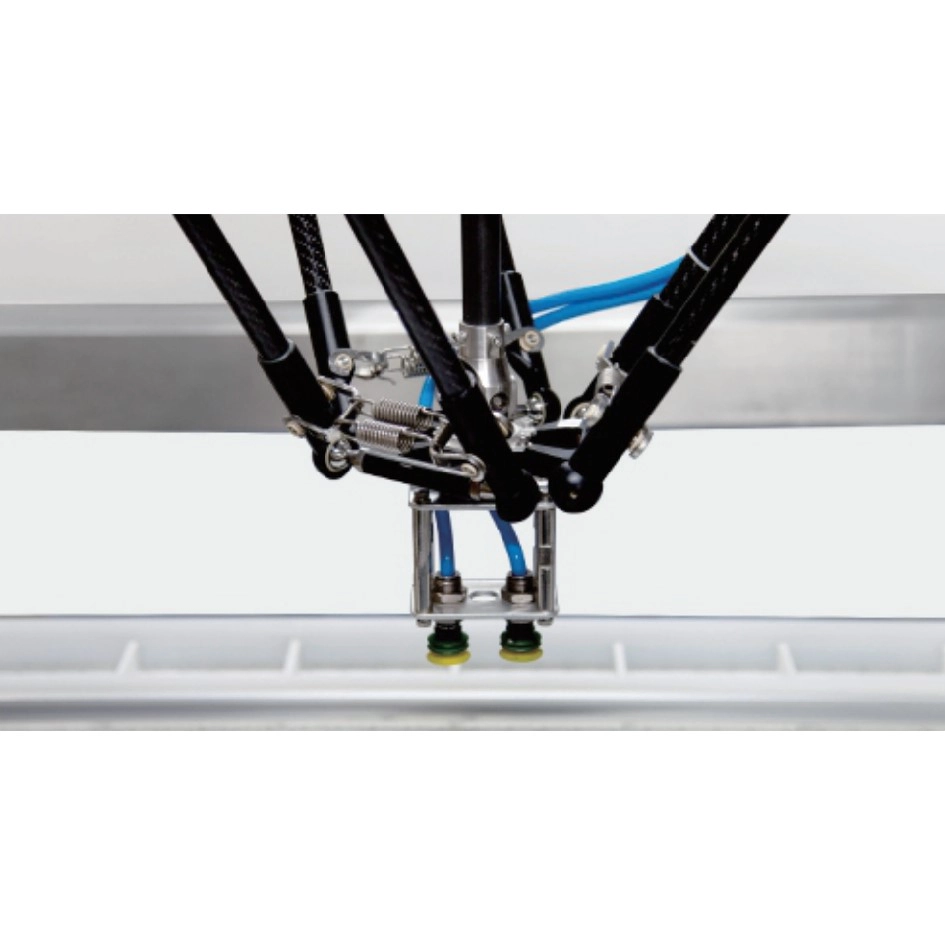

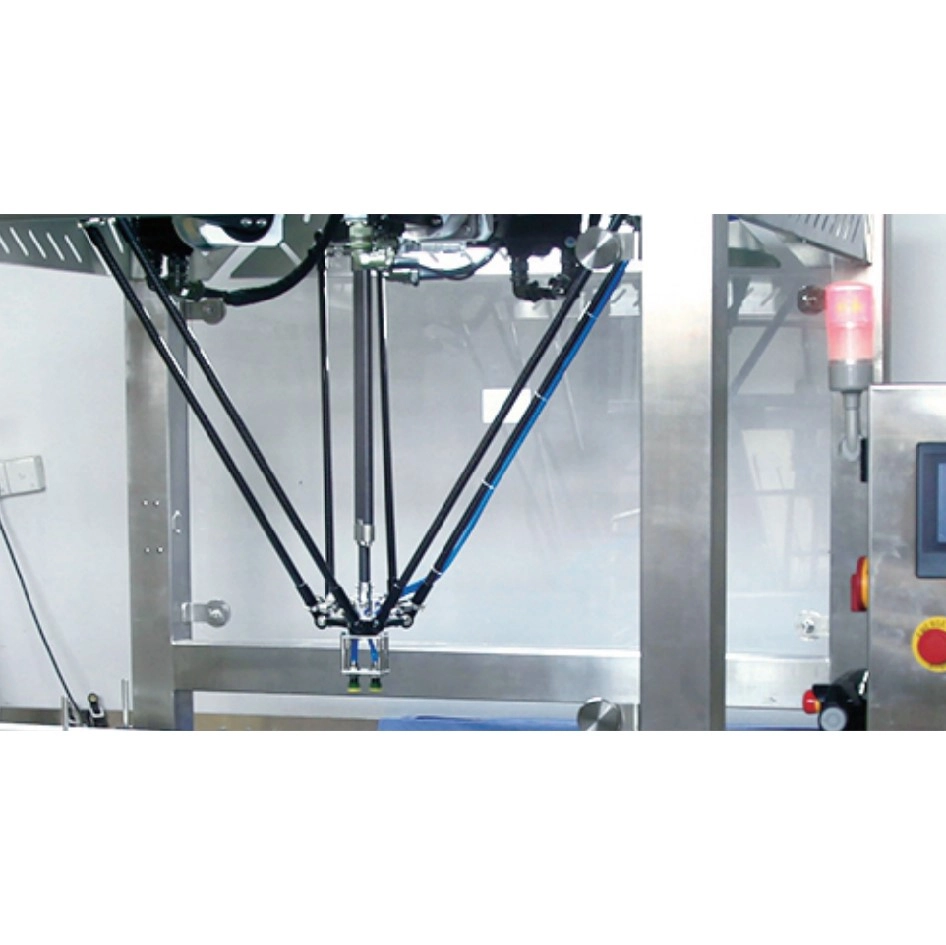

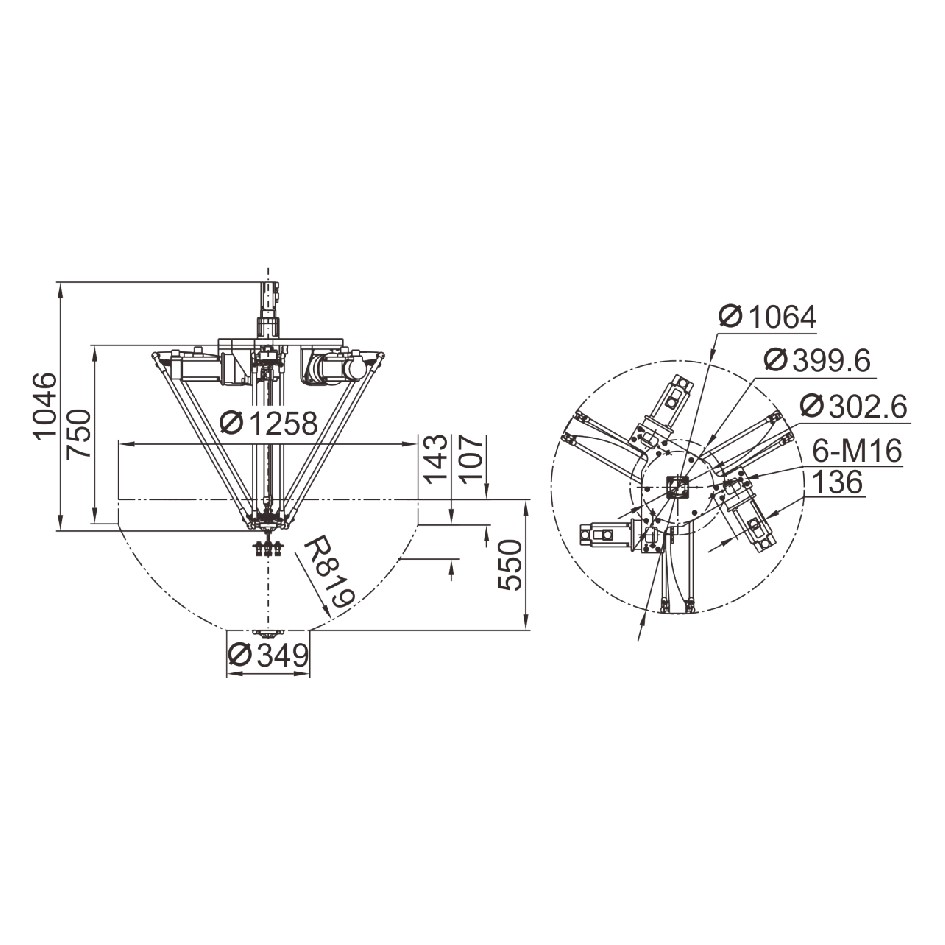

The parallel manipulator features a 4-axis linkage structure and a high-precision servo control system, ensuring accurate and reliable operation. It can be integrated with a vision system or onboard conveyor, supporting customized conveying solutions with flexible configuration options. This system is ideal for automated handling of various materials across industries such as food, pharmaceuticals, condiments, plastics, handicrafts, electronics, and more.

Kenwei Production Lines: Boosting Efficiency and Precision in Automated Packaging

Kenwei, a renowned leader in packaging machinery, proudly offers advanced Production Lines designed to streamline your entire automated weighing and packaging processes. As a powerful manufacturer specializing in multi-head weighers, metal detectors, linear weighers, and check weighers, Kenwei is dedicated to delivering high-speed, high-precision solutions that cater to diverse production needs.

Located in the innovative Fusha High-tech Industrial Park, Guangdong, our facility is equipped with a state-of-the-art automated weighing and packaging system. Kenwei’s Production Lines are crafted to optimize efficiency while ensuring the highest product quality standards. We provide comprehensive support—ranging from design, development, manufacturing, and installation to technical training and attentive after-sales service.

What truly sets Kenwei apart is our commitment to customized solutions. We listen to your requirements and tailor our systems to fit your unique production environment, giving you a one-stop platform to solve all your weighing and packaging challenges. Our excellent brand reputation is built on fast, thoughtful service and top-quality machines that you can trust.

By choosing Kenwei Production Lines, you are not only investing in leading-edge technology but also in a partnership that values your success above all. Let us help you transform your factory with automated lines that deliver accuracy, speed, and reliability—every single time.

Picture Show

Certificate display

Intellectual Property Management System Certification

Trademark Certificate-Keiwei Jingwei

Q&A

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

If you have any questions about our goods or services, please feel free to contact us.

Parallel Robot Pick and Place System for Automated Packaging and Production Lines

The parallel manipulator features a 4-axis linkage structure and a high-precision servo control system, ensuring accurate and reliable operation. It can be integrated with a vision system or onboard conveyor, supporting customized conveying solutions with flexible configuration options. This system is ideal for automated handling of various materials across industries such as food, pharmaceuticals, condiments, plastics, handicrafts, electronics, and more.

Two Outlet Semi Auto Sugar Weighing and Packaging Machine JW-B16

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

Double inlet rotary packaging and weighing system JW-B9

The JW-B9 Double Inlet Rotary Packaging and Weighing System offers fully automatic feeding, weighing, bag filling, date printing, and output. Ideal for fluffy, irregular, or easily blocked materials, it ensures smooth, strong sealing and continuous high-speed operation. Suitable for snacks, puffed foods, hardware, and plastics, it supports seamless integration with conveyors and labelers to boost efficiency and reduce labor costs.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei