Kenwei Parallel Manipulator for Automated Packaging Efficiency

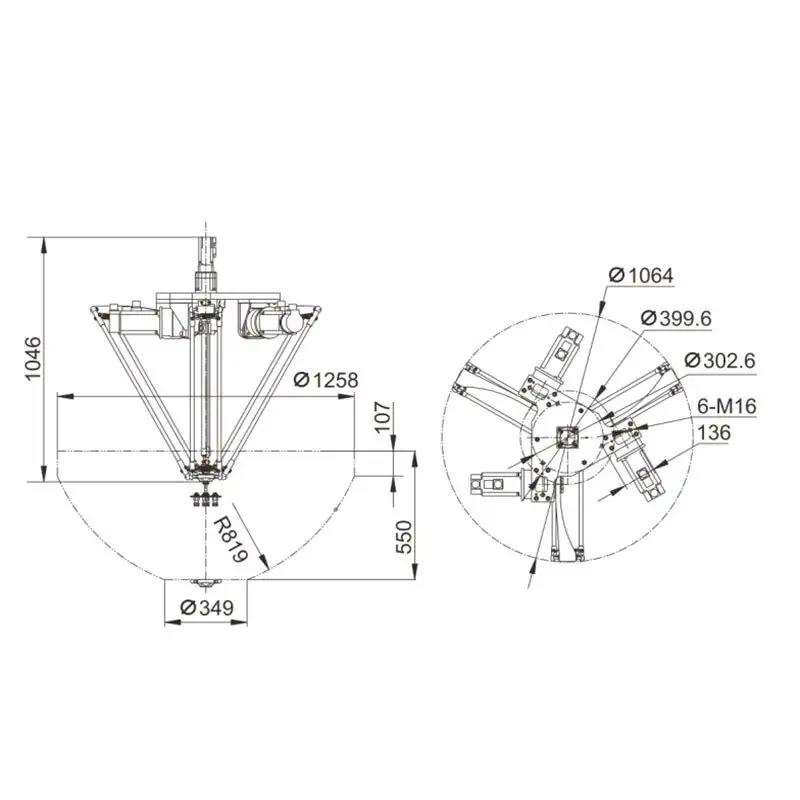

The parallel manipulator adopts a 4-axis linkage structure and servo control system to ensure the accuracy of working applications. The parallel manipulator can be equipped with visual or onboard conveying and an integrated application, which supports customized application of the conveying section and has flexible configuration. It is suitable for all kinds of transportation materials in food, medicine, condiments, plastics, handicrafts, electronics and other industries.

Kenwei Parallel Manipulator: Enhance Packaging Efficiency with Precision Automation

Discover the future of intelligent packaging solutions with the Kenwei Parallel Manipulator, designed and manufactured by Guangdong Kenwei Intellectualized Machinery Co., Ltd. As a global leader in automated weighing and packaging equipment, Kenwei brings you an advanced parallel manipulator integrated seamlessly with your production line to boost efficiency and accuracy.

Our parallel manipulator offers rapid and precise handling of products, making it the ideal solution for tasks requiring consistent high-speed performance. With its refined movement and reliable stability, Kenwei’s manipulator ensures smooth product transfer, sorting, and assembly operations, significantly reducing manual labor and operational errors.

Crafted to integrate effortlessly with Kenwei’s celebrated multi-head weighers and other packaging systems, this manipulator is customizable to meet your unique production requirements. Whether you’re in the food, pharmaceutical, hardware, or other industries, our parallel manipulator simplifies complex processes, maximizes throughput, and minimizes downtime.

At Kenwei, we understand that your business deserves care and attention. Our solutions deliver not just machinery but peace of mind—supported by our expert technical training, 24/7 after-sales service, and comprehensive installation support. Trust in Kenwei to provide reliable, efficient, and intelligent automation tailored to your needs.

Elevate your packaging operations with the Kenwei Parallel Manipulator—where precision meets productivity.

Product Images

Our Certifications

Multhead conbiration weigher

Packging machine

2016 high tech enterprise certificate

Frequently Asked Questions

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

Automatic Dual-Axis Industrial Robotic Arm for Packaging and Production Automation

This product is a standard two-axis parallel manipulator with simple structure, beautiful appearance, convenient installation and maintenance, small space occupation and high reliability. It adopts modular design, easy debugging, long life, low maintenance cost, and supports multi-angle visual control. It has the function of grabbing and placing, equipped with automatic positioning of the visual system, and realizes automatic stacking and sorting.

Parallel Robot Pick and Place System for Automated Packaging and Production Lines

The parallel manipulator features a 4-axis linkage structure and a high-precision servo control system, ensuring accurate and reliable operation. It can be integrated with a vision system or onboard conveyor, supporting customized conveying solutions with flexible configuration options. This system is ideal for automated handling of various materials across industries such as food, pharmaceuticals, condiments, plastics, handicrafts, electronics, and more.

Combined weighing and packaging machine with screw feeder for powder materials

The Kenwei combined weighing and packaging machine with screw feeder is ideal for powder packaging. This advanced weighing and packaging machine of powder ensures high precision and efficiency, making it your top choice power packaging machine for powder materials.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei