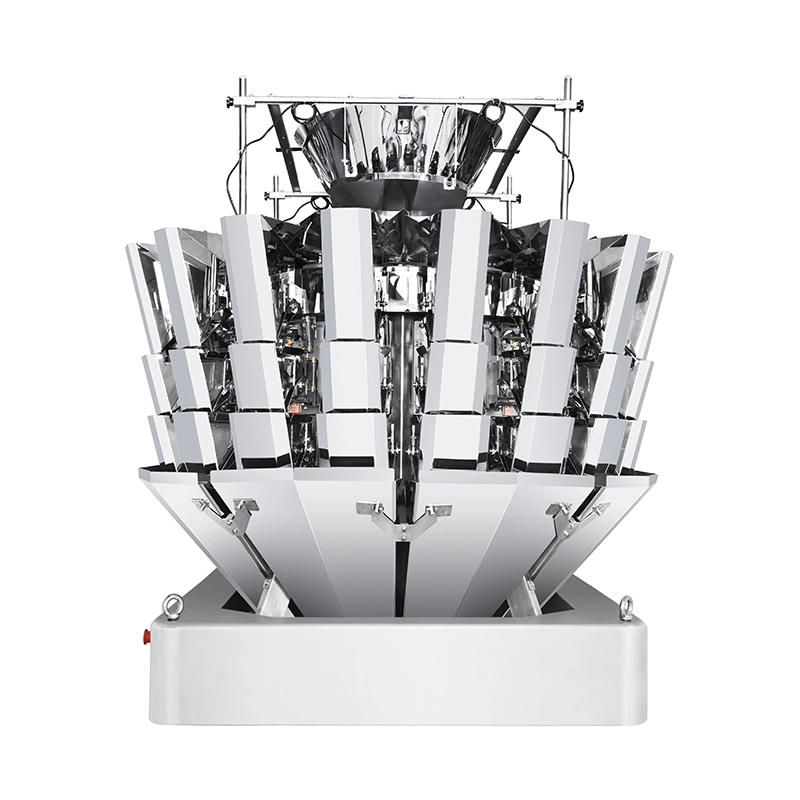

Kenwei Automatic Multihead Weigher Packer

Kenwei Automatic Multihead Weigher Packing Machine

In today's fast-paced production environment, efficiency and precision are paramount. Businesses across various industries demand packaging solutions that not only keep pace but also guarantee accuracy, minimize waste, and enhance productivity. Kenwei understands these critical needs.

Introducing the Kenwei Automatic Multihead Weigher Packing Machine – your solution for streamlined, high-performance product packaging. Engineered for excellence, this integrated system combines our renowned high-speed, high-precision multihead weighers with robust packaging capabilities to deliver an unparalleled automated experience.

Imagine significantly boosting your output while ensuring every package contains the exact weight. Our machine achieves this by utilizing advanced weighing technology, minimizing product giveaway and maximizing profitability. Whether you're handling granular products, snacks, confectionery, or frozen foods, the Kenwei automatic multihead weigher packing machine adapts seamlessly, ensuring optimal performance for diverse applications. Its automated operation reduces manual labor dependency, leading to lower operational costs and a safer working environment. We empower your business to achieve consistent quality and faster turnaround times, giving you a competitive edge.

At Kenwei, we pride ourselves on being a powerful manufacturer, dedicated to innovation in weighing and packaging technology. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, our comprehensive capabilities span design, manufacturing, marketing, installation, training, and robust after-sales service. We don't just sell machines; we provide one-stop automated weighing and packaging solutions tailored to your unique customization requirements. Our vision is clear: to become the world's leading weighing packing machine manufacturer, a commitment reflected in every high-speed, high-precision machine we build and every customer relationship we nurture. You are valued, and your operational success is our priority.

Ready to transform your packaging process? Discover how the Kenwei Automatic Multihead Weigher Packing Machine can elevate your business. Visit our website at https://www.kenweigroup.com/ or contact us today for a tailored consultation.

Product Images

Certifications

ICR Polska/VC/LU201101 Conveyor

Mixing weighing method and mixing equipment - patent certificate

Trademark Certificate-Jingwei

Q&A

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

If you have any other questions, please write email to us or call us , we will reply you ASAP.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

14 Head Multihead Weigher Packaging Machine for Weighing and Packaging Dumplings Wontons

The weighing sensor has high-precision, high-standard professional performance and adopts intelligent multi-sampling stable mode to significantly improve weighing accuracy. It also has an intelligent fault alarm function, making maintenance more efficient and convenient. The equipment supports high-speed wrong material unloading, effectively avoiding material blockage. The overall structure adopts a highly integrated modular design, integrates CAN bus technology, and applies Modbus industrial standard communication protocol to achieve seamless integration of the combined weighing system and the packaging machine.

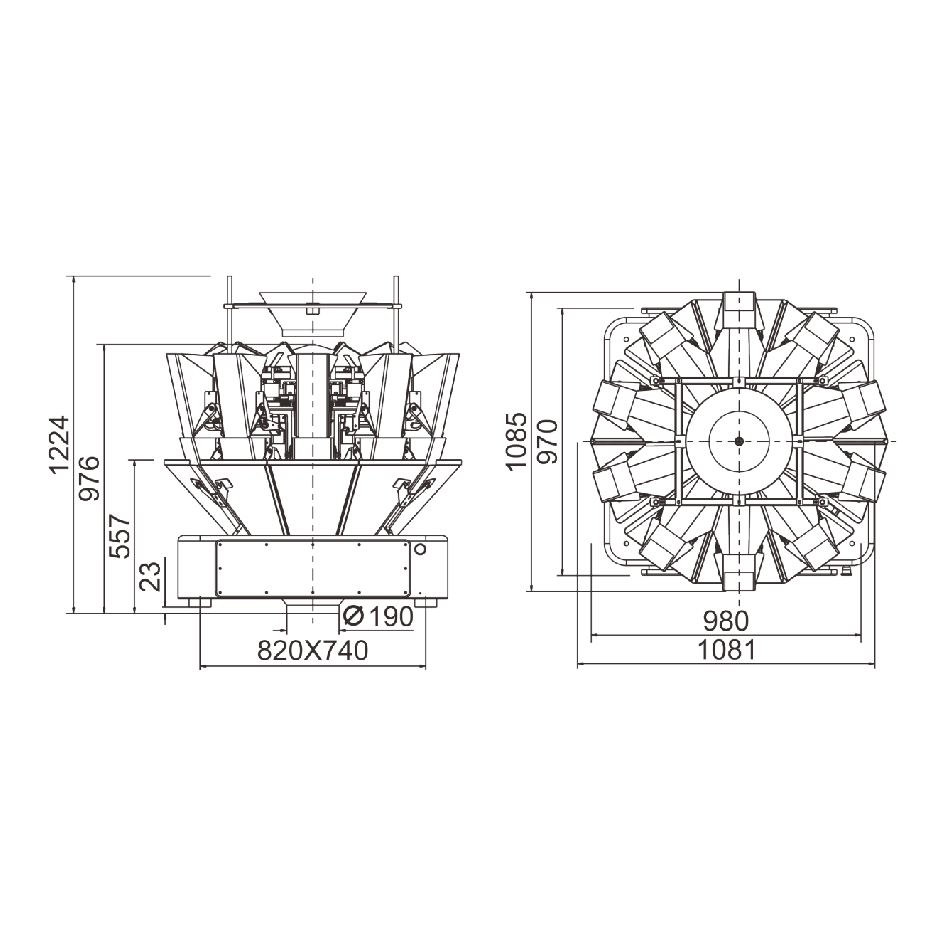

High Precision 3-Layer 18-Head Standard Weigher for Accurate and Efficient Weighing

The High-Precision 3-Layer 18-Head Standard Weigher is designed for accurate weighing of a wide range of materials, including granular, flake, round, irregular, and puffed items like nuts, seeds, candies, and snacks. It features a separate vibration plate for mixed material applications, a Ling-shaped hopper for faster and more concentrated discharge, a memory bucket for improved accuracy, and an integrated chassis for enhanced stability. Ideal for high-precision, efficient weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei