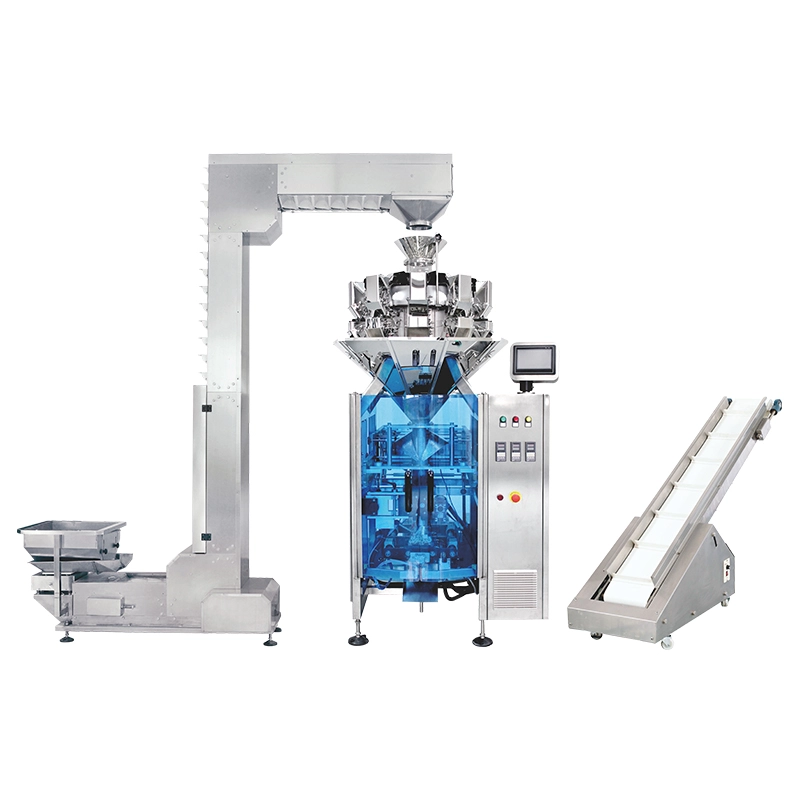

Kenwei Automatic Multihead Weigher Packing Machine – High Speed & Precision

The JW-B4 Combined Multihead Weighing and Packaging Machine with Z Conveyor is a compact, fully automatic solution ideal for packing snacks, nuts, candies, pet food, frozen products, hardware, and more. It integrates feeding, weighing, filling, sealing, and labeling with high precision and speed. Suitable for a wide range of materials, it’s perfect for space-limited production lines.

Kenwei, a leading manufacturer in the weighing and packaging industry, proudly presents its automatic multihead weigher packing machine – a perfect blend of speed, accuracy, and reliability. Designed to meet the needs of various industries, this machine offers precise weighing combined with efficient packaging, ensuring your production line runs smoothly and effectively.

Our automatic multihead weigher packing machine is engineered to deliver rapid and accurate measurement of products, reducing material waste and improving consistency. Whether you package snacks, frozen food, granules, or other items, Kenwei’s machine handles them all with ease. Thanks to its multihead design, it can weigh multiple product portions simultaneously, reaching high output rates without sacrificing precision.

Kenwei is based in Guangdong Province’s Fusha High-tech Industrial Park, where innovation meets manufacturing excellence. We offer comprehensive services including product design, manufacturing, installation, commissioning, and ongoing technical support. Our focus is not only on delivering advanced machinery but also on providing one-stop automated weighing and packaging solutions customized to your specific needs.

Customers trust Kenwei because we combine cutting-edge technology with user-friendly operation. Our machines feature intuitive controls and sturdy construction, ensuring minimal downtime and long-term stability. We prioritize fast service and thoughtful support, helping you achieve maximum productivity and seamless integration with your packaging lines.

At Kenwei, we envision becoming the world’s top multihead weigher and packing machine manufacturer. Our commitment to quality and customer satisfaction drives every aspect of our work. Experience the difference with Kenwei’s automatic multihead weigher packing machine and take your packaging process to the next level.

Discover more at (https://www.kenweigroup.com/) and join countless businesses worldwide that rely on Kenwei for accurate, efficient, and reliable packaging solutions.

Picture Show

Certificate display

Advanced Award for High Quality Development of Enterprises

PA Combination Scale

ICR Polska/VC/LU201103 Finished Product Conveyor

Frequently Asked Questions

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei