How to Choose the Right Multihead Weigher: A Guide to High-Speed, High-Precision Food Packaging with Kenwei

To meet these requirements, manufacturers—especially those in the food industry—have widely adopted advanced packaging and weighing inspection equipment. Among these, multihead weighers (also known as combination scales) are particularly popular due to their accuracy, speed, and adaptability.

Analog vs. Digital Combination Scales

Currently, two main types of combination scales exist globally:

-

Analog Signal Combination Scales

-

Digital Signal Combination Scales

While the technology is mature, the choice between these two types significantly affects weighing precision. Analog models are often less stable and may suffer from issues such as motherboard burnout or unreliable second-hand components. In contrast, digital combination scales, like those manufactured by Kenwei, offer higher precision and better stability. All Kenwei models use digital high-precision load cells and waterproof construction, making them ideal for demanding food processing environments.

Applications of Multihead Weighers in Food Packaging

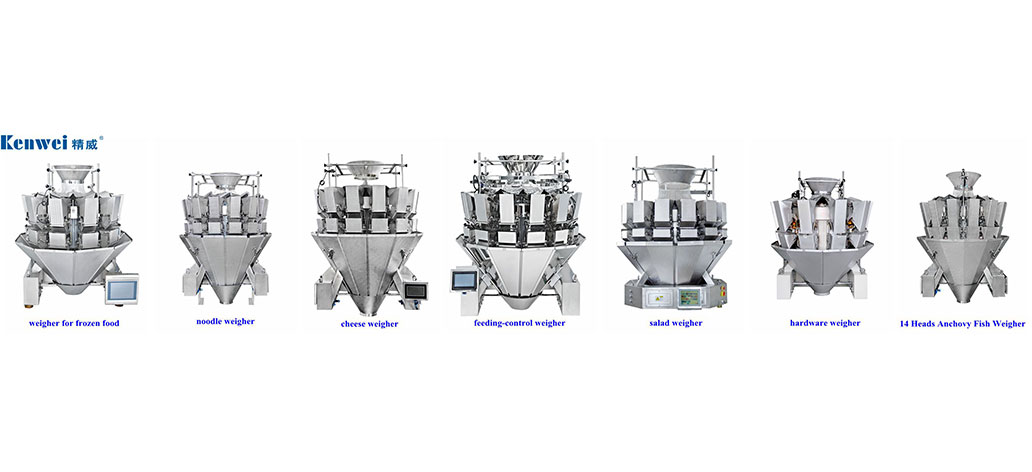

Kenwei's multihead weighers are designed for automatic, high-speed, and high-precision weighing of irregular bulk products, including:

-

Puffed foods

-

Candies and melon seeds

-

Nuts like pistachios and almonds

-

Jelly and frozen food

-

Snacks, pet food, hardware, and plastic parts

These systems are engineered to handle a wide range of shapes, sizes, and material properties.

What to Consider When Choosing a Combination Scale

1. Weighing Accuracy

The primary reason for choosing a combination scale is to reduce product giveaway and improve packaging efficiency. Buyers should first understand the permissible error limits for their products based on weight categories. For example:

| Net Weight (Q) | Maximum Deviation (T) |

|---|---|

| 5–50g | 9% |

| >50–100g | 4.5g |

| >100–200g | 4.5% |

| >200–300g | 9g |

| >300–500g | 3% |

| >500–1000g | 15g |

| >1000–10000g | 1.5% |

| >10000–25000g | 1% |

Kenwei’s scales use self-developed anti-interference technology and internationally recognized load cells to achieve high display and actual accuracy. For example, it’s estimated that a medium-sized food manufacturer using Kenwei equipment can save over ¥100,000/month in reduced overfill—paying off the investment in under three months.

-

Net content Q

minus deviation T

Net content Q

minus deviation T

Net content Q

minus deviation

T

5 - 50g

﹥ 50-100g

﹥ 100-200g

9%

4.5g

4.5%

﹥ 200-300g

﹥ 300-500g

﹥ 500-1000g

9g

3%

15g

1000-10000g

﹥ 10000-15000g

﹥ 15000-25000g

1.5%

150g

1%

2. Speed Requirements

In addition to accuracy, speed is a major factor. Typical speeds include:

-

10-head scale: 70 packs/min

-

14-head scale: 120 packs/min

-

24-head scale: 240 packs/min

Kenwei's high-speed models are ideal for operations requiring fast throughput. However, it's also crucial to match the scale with upstream conveyors and downstream packaging machines to ensure a seamless production line.

3. Material Characteristics and Volume

When packaging materials of varying densities, customers should not only consider the maximum weighing capacity but also the maximum volume capacity. This is because two items of the same weight can differ greatly in size depending on their density.

Kenwei addresses this challenge with intelligent triple-stability technology and customized vibration systems. The vibration amplitude and duration are automatically adjusted for optimal flow and accuracy, even for difficult-to-handle materials like fragile items, sticky products, or powders.

Why Choose Kenwei?

China’s domestic combination scale market is growing, but quality and reliability vary significantly among manufacturers. Kenwei, a top-three brand in China’s combination scale industry, has earned its reputation for quality, performance, and innovation.

Key highlights include:

-

Over 13 years of experience in the combination scale industry

-

More than 5,000 machines sold in 2017 across 87 countries

-

7,000 units annual production capacity with semi-automated manufacturing

-

A full range of solutions including metal detectors, manipulators, and complete packaging lines

-

Awarded the Guangdong Province Production, Learning, and Research Technology Project Award

Kenwei continues to lead the industry with specialized weighing and packaging solutions for food, pharmaceuticals, plastic hardware, and more.

Conclusion

In today’s competitive market, selecting the right combination scale can make a significant difference in efficiency, cost savings, and compliance. Kenwei’s multihead weighers offer unmatched accuracy, high speed, and proven reliability, making them the preferred choice for manufacturers seeking to modernize and optimize their packaging processes.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei