The Evolution and Technological Advancements of Kenwei Multihead Weighers in Prepackaging Solutions

1. Overview

Multihead weighers are intelligent combination weighing and packaging devices designed to improve accuracy and speed in quantitative packaging. Traditional single-bucket systems worked well with uniformly sized particles, using simple controls like delay sampling and drop correction to achieve weighing goals. However, modern food packaging demands the ability to handle irregular materials such as dried fruits, puffed snacks, candy, pet food, and other bulk items with inconsistent shapes and sizes.

As prepackaged food becomes dominant in urban markets, especially with the rise of supermarkets, the limitations of conventional scales become apparent. Traditional systems struggle with both accuracy and efficiency when handling uneven products. This need has driven the development and adoption of high-performance multihead weighers capable of efficiently managing non-uniform items.

2. The Development of Multihead Weigher Technology

In the 1970s, most bulk foods in China were sold unpackaged, with manual weighing and pricing performed in stores. By the 1980s, with the introduction of advanced electronic scale technology from abroad, electronic weighing systems were implemented. These early systems still relied on manual packing and offered limited efficiency, with speeds below 10 packs per minute.

To improve packaging rates, single-bucket vibration-feeding packaging machines were developed in the late 1980s, offering speeds of around 20 packs/min but requiring uniform particle sizes. Weighing accuracy often suffered, and the technology was not suitable for a wide range of food products.

As food manufacturers demanded faster, more hygienic, and accurate packaging systems for irregular granular materials, computer-controlled multihead weighers emerged. These scales use a combination of multiple weighing buckets and intelligent algorithms to achieve precise and fast packaging of uneven items. This development marked a new era in the quantitative packaging industry.

3. Operating Principle of a Multihead Weigher

Materials are fed into a storage hopper via a conveyor. A photoelectric sensor monitors the material level and controls the conveyor's operation. Materials then pass through a vibrating plate to buffer hoppers, and finally into weighing hoppers.

Each weighing hopper, equipped with a load cell, measures the material's weight and sends data to a central microprocessor. The computer runs combination calculations (e.g., 2^14 - 1 = 16,383 combinations for a 14-head weigher) to find the optimal combination of buckets that meets the target weight.

Typically, each pack uses 3-5 weighing hoppers. The selection, release, and refilling processes happen in rapid succession. The entire weighing and packaging cycle takes about 1200ms, with a possible speed of up to 80 packs/min. Systems with dual scales and memory hoppers can reach speeds of 240 packs/min.

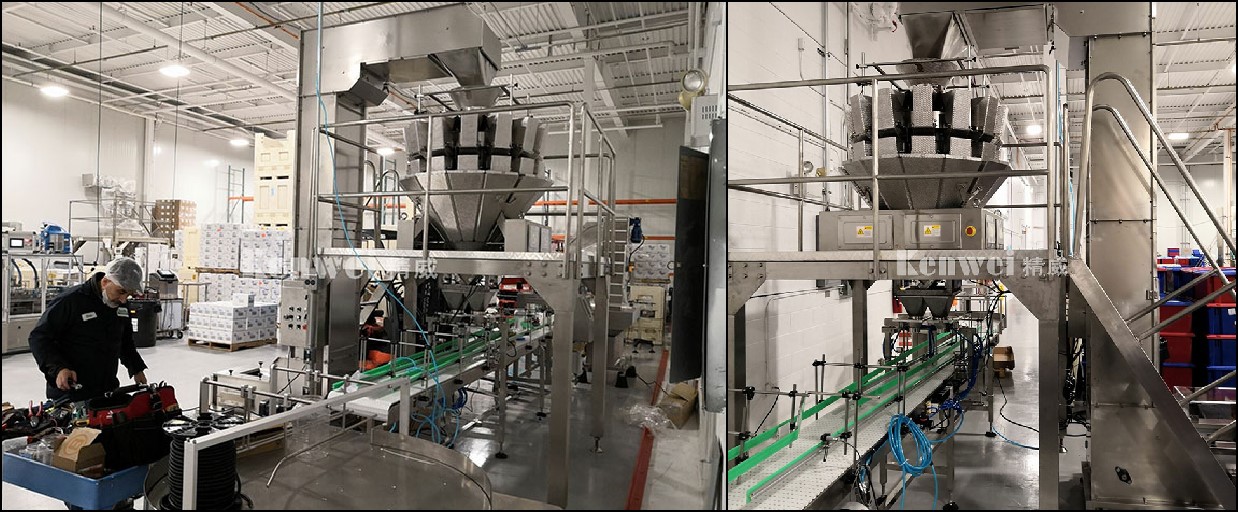

4. Advanced Kenwei Multihead Weigher Technology

Kenwei's multihead weighers stand out with their modular, intelligent design. Weighing heads can be configured with 10, 14, 20, or 32 heads and feature memory buckets, stepper motor-driven hopper doors, and plug-and-play sealed drive units for easy maintenance.

Each drive unit includes essential intelligent components like load cells, stepper motors, and control modules, pre-tested and interchangeable across models. The machine's components, including mirror-polished stainless-steel hoppers, are IP65-rated for water and dust resistance, and can be disassembled without tools.

Kenwei software supports various packaging modes, ensuring compatibility with a broad range of materials. The latest models offer advanced diagnostics:

-

Real-time motor status display

-

Weight accuracy monitoring

-

Printer operation status

-

LAN connection verification

-

Memory module checks

-

A/D conversion monitoring

-

Loadcell waveform tracking with automatic fault detection

5. Economic Impact and Future Outlook

With regulations like OIML R87 and China's Technical Supervision Bureau Order 43, precision in prepackaging is now mandatory. Kenwei's multihead weighers significantly reduce material waste and labor costs.

Example: For a 100g bag of chocolate candy priced at ¥16, manual packaging often results in 2g overfill, while Kenwei systems limit this to 0.5g—a saving of 1.5g or ¥0.24 per bag. At a production rate of 33,600 bags per day over 300 days, this results in material savings worth ¥2.42 million annually. When labor savings are factored in, the economic advantages are even greater.

Multihead weigher technology, particularly from Kenwei, is leading the transition from traditional to smart, high-efficiency packaging systems, driving greater precision, reduced waste, and stronger profitability across industries.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei