How to Choose the Right Multihead Weigher for Your Packaging Needs

Selecting the right multihead weigher is crucial for improving packaging efficiency, accuracy, and product quality. This guide covers key factors such as capacity, accuracy, applicable industries, price, quality, brand reputation, and after-sales service to help you make the best choice.

1. Determine Capacity and Accuracy Needs

When choosing a combination weigher, capacity and accuracy are key factors.

-

Capacity: Large-capacity multihead weighers are suitable for bulk products but may sacrifice precision.

-

Accuracy: High-precision models offer better measurement consistency but usually handle smaller volumes.

-

Measurement Range: Ensure the target product’s weight falls within the weigher’s range to avoid inaccurate results.

Example: If you regularly package products heavier than the machine’s limit, your readings will be unreliable. Always match your machine’s capacity to your product weight and precision requirements.

2. Match the Weigher to Your Industry

Different industries require different weighing solutions.

-

Large-volume products like potatoes, onions, or vegetables work best with salad multihead weighers.

-

Fragile items such as biscuits, peanuts, or puffed snacks require breakage-proof multihead weighers to prevent damage.

-

Counting function weighers are ideal when you need to calculate quantity by weight.

By choosing a machine specifically designed for your material type, you’ll improve efficiency and reduce product waste.

3. Balance Price and Quality

While high-quality multihead weighers may require a larger initial investment, they deliver long-term value by:

-

Reducing maintenance costs

-

Offering higher accuracy

-

Lasting longer with stable performance

Cheaper models may save money upfront but often lead to more repairs and downtime.

4. Consider Brand and After-Sales Support

Opt for reputable brands that provide:

-

Warranty coverage

-

Technical support

-

Spare parts availability

Strong after-sales service ensures minimal downtime and reduced costs if a problem arises.

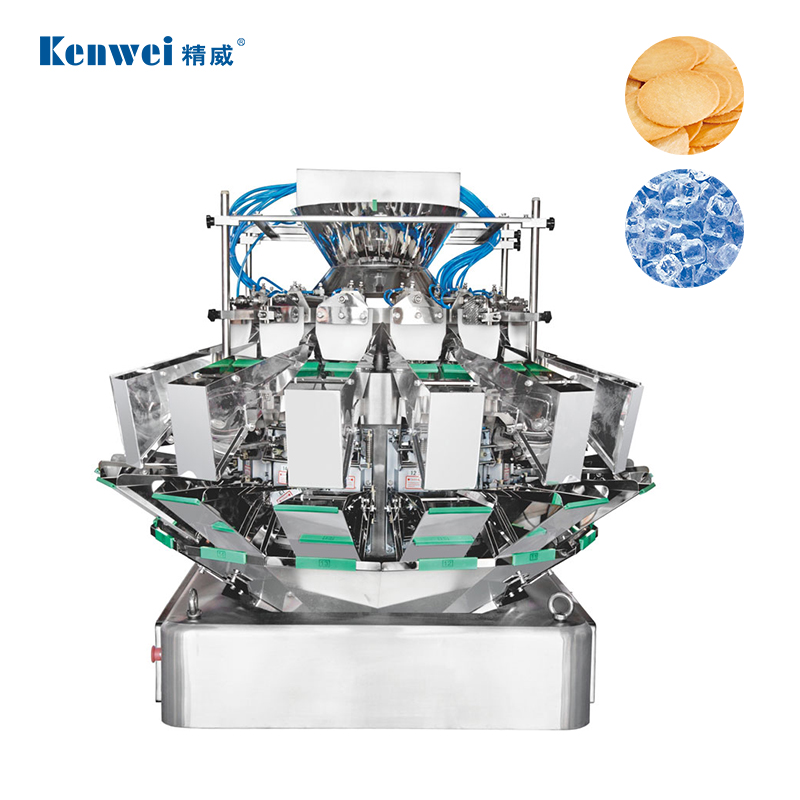

5. Why Choose Kenwei

Founded in 2006, Guangdong Kenwei Intellectualized Machinery Co., Ltd. has become a leader in packaging machinery manufacturing. We specialize in:

-

High-speed, stable, and precise multihead weighers

-

Linear weighers, check weighers, metal detectors, and conveyor systems

-

Fully customized automatic quantitative packaging systems to meet diverse industry needs

With our advanced technology and commitment to quality, Kenwei delivers solutions that enhance efficiency and reliability for global customers.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei