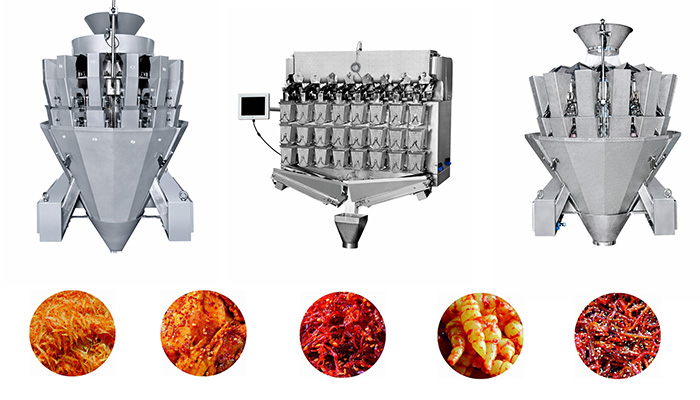

How to Maintain and Clean a Multihead Weigher for Maximum Efficiency

A multihead weigher is essential for automated packaging lines, offering high efficiency and accuracy. Proper cleaning and maintenance not only extend its service life but also ensure optimal performance. Kenwei shares practical tips for maintaining different models and material types.

1. Importance of Multihead Weigher Maintenance

As the core equipment in automated packaging systems, the multihead weigher significantly boosts production efficiency and economic returns. Built with durable 304 stainless steel, most units last over 10 years. However, regular cleaning and proper maintenance are crucial for preserving weighing accuracy and maximizing value.

2. Safety Precautions Before Maintenance

-

Always cut off the power and unplug the machine before performing any maintenance or testing.

-

Only professionally trained personnel should conduct maintenance.

3. Cleaning Methods for Different Applications

A. Non-Waterproof Models for Conventional Materials

Used for items like melon seeds, peanuts, candy, and snacks:

-

Use an air gun to blow off dust from the main vibration plate, line vibration plate, display, chute, etc.

-

Wipe surfaces with gauze dipped in neutral cleaning fluid (e.g., alcohol).

-

Detachable parts can be removed and washed in 30–50℃ warm water.

-

Cleaning frequency: typically once a week, depending on production.

B. Waterproof Models for Conventional Materials

Used for frozen dumplings, sweet dumplings, salads, and cooked food:

-

Turn on the cleaning button.

-

Switch off the power.

-

Use a shower rinse (follow the waterproof rating).

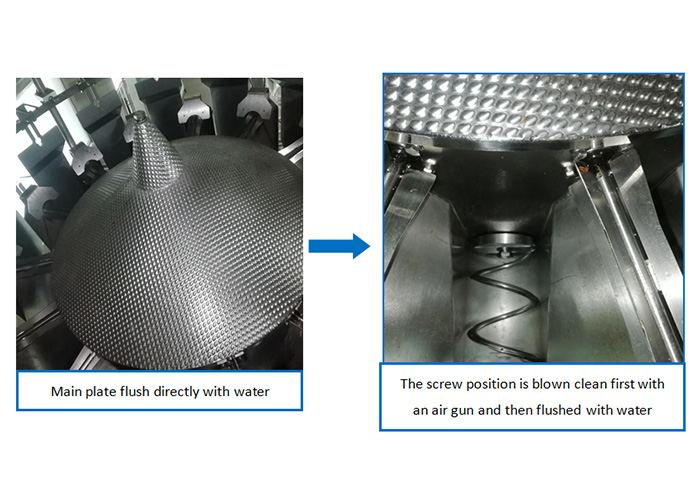

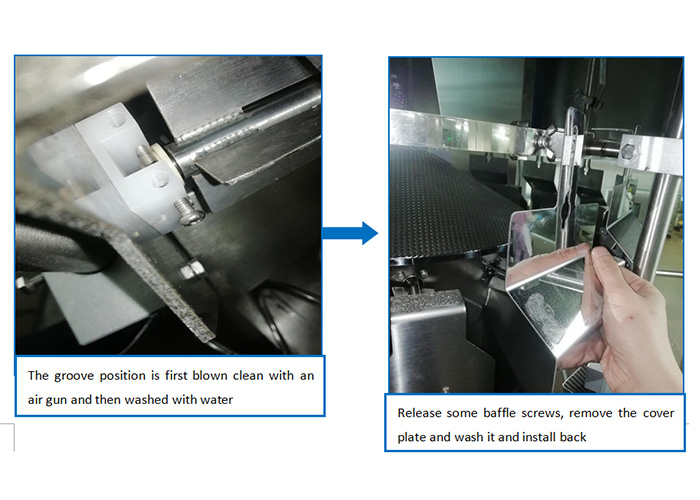

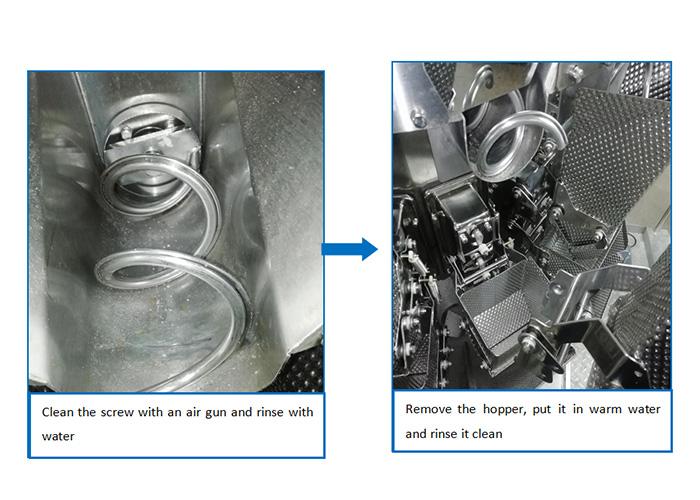

C. Non-Waterproof Models for Viscous Materials

Used for pickles, mustard greens, spicy small fish, etc.:

-

Disassemble parts and soak them in warm water for 5 minutes.

-

Clean using neutral detergent or soap.

D. Waterproof Models for Viscous Materials

Used for sauce cucumbers, dried radish, etc.:

-

Turn on the cleaning button.

-

Switch off the power.

-

Rinse directly with a shower (respecting waterproof level).

4. Kenwei’s Multihead Weigher Advantages

Guangdong Kenwei Intellectualized Machinery Co., Ltd. manufactures high-quality 304 stainless steel weighers with easy-to-disassemble parts. Available in non-waterproof, waterproof, and high-waterproof models, they are trusted by packaging machine manufacturers and food producers for reliability and ease of cleaning.

5. Conclusion

Proper cleaning and maintenance are key to ensuring your multihead weigher delivers accurate weighing, long service life, and high productivity. By choosing the right model and following the correct cleaning procedures, you can maximize both efficiency and profitability in your packaging operations.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei