History and Applications of Multihead Weighers

This article introduces the history, working principle, and global development of multihead weighers. From Ishida’s first model in the 1970s to today’s advanced systems, it highlights how this technology improves packaging speed and accuracy. It also showcases the rise of Chinese brands like Kenwei in the global market.

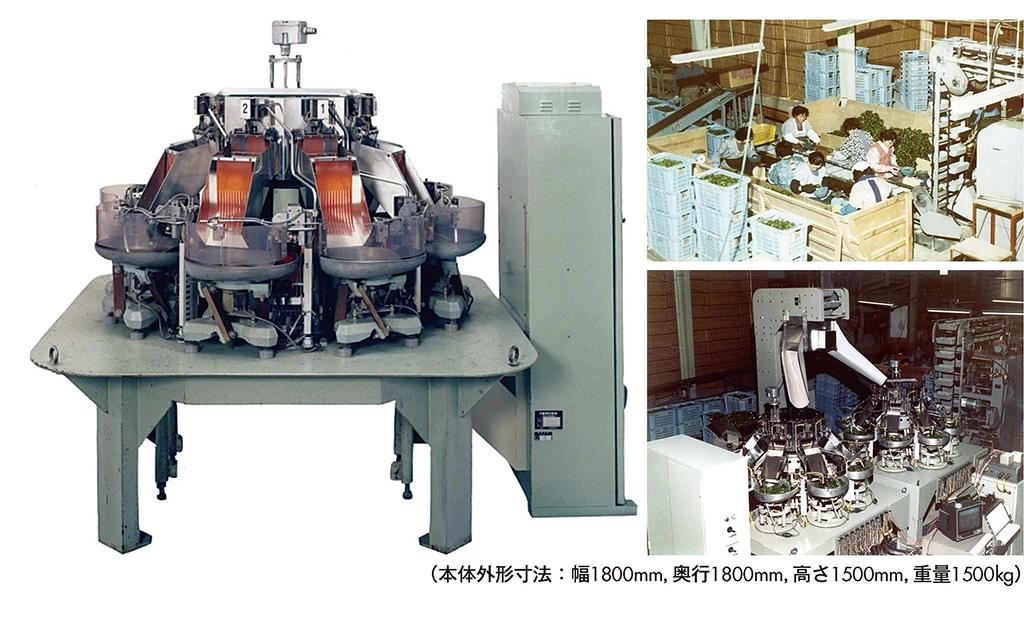

In the 1970s, Japanese company Ishida pioneered the development of the world’s first multihead weigher—a conical machine consisting of eight load cells. Originally designed for the automatic weighing and packaging of green peppers, the machine offered an impressive weighing accuracy of ±2 grams for 150g targets and operated at speeds of 50 to 60 bags per minute. This invention marked the beginning of a “weighing revolution”.

The multihead weigher significantly enhanced production line efficiency and accuracy, enabling fast and precise quantitative packaging. By using advanced combination algorithms, the system automatically selects the optimal combination of weight values from multiple weigh heads to achieve the closest total weight to the target. This fundamental principle—coordinated operation of multiple independent weighing units—results in high-speed, high-accuracy dynamic weighing, reducing human error and dramatically increasing throughput. Today, multihead weighers are widely used across various global industries, particularly in food and consumer goods packaging.

I. Development History

In 1972, Ishida introduced the world’s first multihead combination weigher.

By the 1980s, the application of multihead weighers expanded beyond food to industries such as confectionery, meat processing, metal parts, and rubber components. Ishida increased the weighing speed of its machines to 160–180 weighments per minute and quickly dominated the Japanese market, setting the foundation for its international expansion.

Key Milestones:

-

1978: Australian companies began importing Ishida multihead weighers.

-

1979: Yamato Scale launched its own multihead weigher with built-in load cells.

-

1980: U.S.-based Heat and Control Inc. signed a strategic marketing partnership with Ishida.

-

1981: Yamato introduced a "dual-shift operation" function, achieving speeds of 120 weighments/min, later improved to 160/min in 1984.

-

1988: Yamato developed the first software for weighing mixed products, enabling accurate combination weighing for blended items.

-

1989: The introduction of touchscreen control panels revolutionized the operation and usability of multihead weighers.

For a time, Ishida held nearly 80% of the global weighing and packaging market. However, as weighing technologies became more accessible and competition from Asia intensified, new players emerged with comparable product quality. Japanese and American manufacturers continued to innovate, and today’s market is defined by diverse, high-performance options from multiple global suppliers.

Over time, the multihead weigher category evolved to suit specific material types. For example:

-

Products with smooth surfaces require specialized chutes and vibration settings.

-

Fragile items benefit from shorter drop distances and cushioning structures.

-

Mixed products utilize combination weighing strategies for precise portioning.

-

Sticky or moist materials like cheese require spiral chutes and Teflon-coated contact surfaces.

Today, multihead weighers continue to dominate the solid product packaging industry. They remain one of the most reliable and accurate automatic weighing solutions, with ongoing innovation in design, materials, and digital control.

II. Working Principle of Multihead Weighers

Although multihead weighers have transformed the packaging industry, the core principle has remained largely unchanged for over 50 years. Their operation involves three main stages:

(1) Loading

Materials are fed onto the top of a conical dispersion table located at the center of the machine. This table vibrates at a set frequency and amplitude, giving materials enough kinetic energy to overcome friction and slide down into radial troughs.

These troughs vibrate independently from the table, distributing materials into individual pool hoppers, each leading to a weigh hopper. The system includes a monitoring module beneath the dispersion table that detects when material is low and automatically triggers additional feeding.

Optimal vibration settings must be adjusted based on the material’s surface friction and flowability. Experienced technicians can fine-tune these parameters to maintain consistent speed and portion control.

In addition to radial trough systems, certain products are better handled using timed vibration systems or screw conveyors, which follow similar principles but are adapted for difficult-to-handle items.

Some machine models use a ladder-type dispersion table, where materials slide down step-like levels and into parallel hopper arrangements designed to match specific material behavior and product shapes.

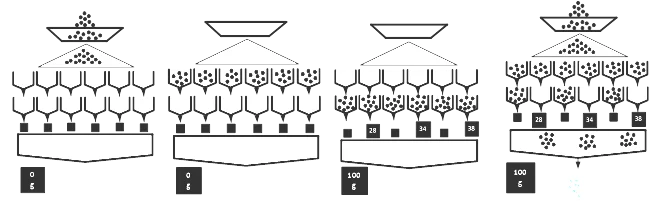

(2) Combination Weighing

After leaving the troughs, materials first enter pool hoppers, and then drop into weigh hoppers below, each equipped with a high-precision load cell.

When the system pauses vibration, the central control unit gathers weight data from all filled weigh hoppers and runs a combination algorithm to calculate all possible weight sums. It then selects the combination of hoppers that yields the closest match to the preset target weight—this is why the system is often referred to as a combination weigher.

The more weigh heads a machine has, the greater the number of possible combinations—improving both accuracy and weighing speed. Modern multihead weighers typically feature 14, 20, or even 30 heads. For high-speed applications, booster hoppers may be added to temporarily store selected combinations before discharge.

In fact, the combination selection algorithm is the main technical differentiator among multihead weighers from different manufacturers. Advanced models may use priority rules, bi-criteria optimization, or even AI-enhanced decision-making to improve performance under complex packaging scenarios.

(3) Discharge

Once the optimal combination is selected, the corresponding weigh hoppers release their contents into the discharge chute, which transfers the product to the packaging machine or downstream processing line.

After discharge, the weigh hoppers reset and begin the next feeding and weighing cycle. This continuous operation dramatically increases packaging line efficiency.

Thanks to the use of combination weighing, the final weight error is typically 1 to 2 orders of magnitude smaller than conventional single-head or manual weighing methods. These accurately weighed products are sealed, packaged, and delivered to market—arriving as the consumer goods on shelves around the world.

III. Development of Domestic Brands

In recent years, Chinese multihead weigher manufacturers have achieved significant technological advancement by adopting and innovating on international technologies. Domestic brands are now offering competitive products with better cost-performance and localized services.

A standout example is Guangdong Kenwei Intellectualized Machinery Co., Ltd., a leading name in China’s automatic weighing and packaging industry. Founded in 2006, Kenwei has focused on the R&D and production of combination weighing systems for nearly two decades.

Today, the company exports to over 100 countries and regions, and has established strategic partnerships with 1,500+ global clients. Known for the stability, accuracy, and cost-effectiveness of its products, Kenwei has become a preferred supplier for many food manufacturers worldwide.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei