Combination Weigher vs Multihead Weigher: Key Differences

- Combination Weigher vs Multihead Weigher: Key Differences

- Overview: why the difference matters for packaging operations

- What is a multihead weigher?

- What is a combination weigher?

- Design and operating principle differences

- Performance comparison (at-a-glance)

- Speed and accuracy — how they trade off

- Product suitability: which machine for which product?

- Footprint, hygiene and cleaning considerations

- Integration with packaging lines and automation

- Total cost of ownership and maintenance

- How Kenwei supports your weighing solution

- Practical selection checklist: choose the right weigher

- Real-world examples and ROI considerations

- Final recommendations

- FAQ — Frequently asked questions

Combination Weigher vs Multihead Weigher: Key Differences

Overview: why the difference matters for packaging operations

Choosing between a combination weigher and a multihead weigher affects throughput, accuracy, product quality and total cost of ownership for your packing line. Both machine families aim to hit target weights quickly and consistently, but they differ in mechanical layout, algorithmic approach, and best-use scenarios. Understanding these differences helps manufacturers select a machine that meets product characteristics (fragility, size, flowability), speed requirements, and integration needs.

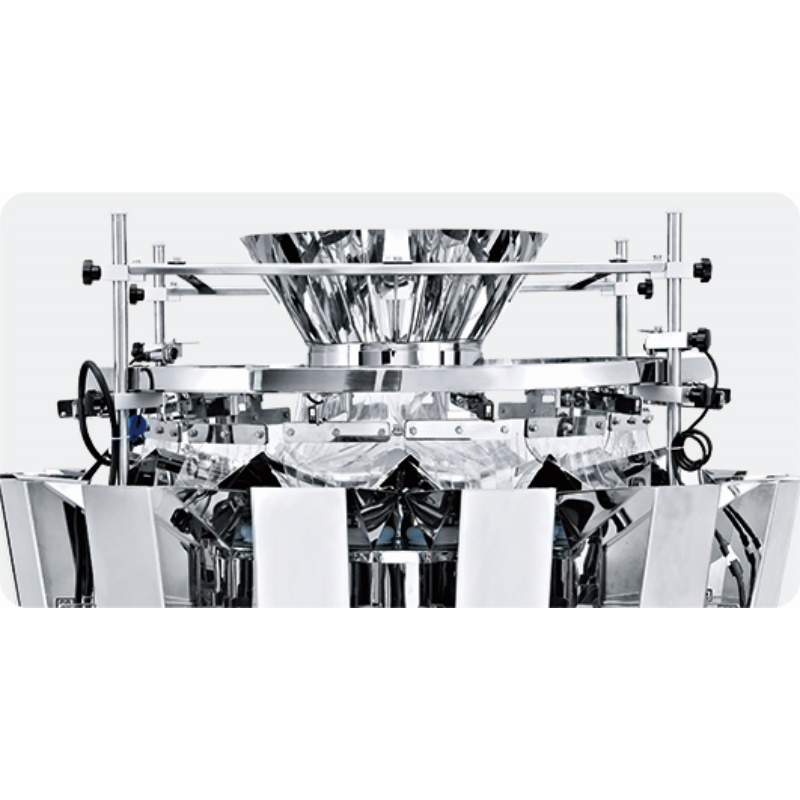

What is a multihead weigher?

A multihead weigher (also called a multi-head scale or combination head weigher in some markets) uses many small weighing hoppers arranged in a circular or octagonal array. Product is fed into distribution trays and then into the weigh hoppers. Advanced software calculates which combination of hopper weights matches the target weight, then discharges selected hoppers into the packer. Multihead weighers are widely used for snacks, confectionery, frozen vegetables, nuts, pet food and other pieces or granules because they are fast, accurate and flexible.

What is a combination weigher?

The term combination weigher is often used to describe systems that rely on combining weights from multiple individual weighers or hoppers to reach a target. In practice this term can refer to smaller multihead-style machines or modular solutions where outputs from several weighing channels are combined algorithmically. Combination weighers can be simpler and more cost-effective for specific applications where very high head counts or ultra-high speeds are unnecessary.

Design and operating principle differences

Multihead weighers typically have a high number of weigh heads (10–24 or more) arranged for fast combinatorial calculations. Combination weighers may use fewer channels or modular weigh units and sometimes integrate linear weighers or vibratory feeders that feed a smaller number of hoppers. The multihead design focuses on parallel weighing and rapid hopper release; combination weighers emphasize combining fewer, larger increments. Both use combination algorithms but differ in mechanical complexity and feeder architecture.

Performance comparison (at-a-glance)

| Feature | Multihead Weigher | Combination Weigher |

|---|---|---|

| Typical head count | 10–24+ heads | 4–14 channels / modular units |

| Typical throughput | 30–300 packs/min (product dependent) | 10–120 packs/min (product dependent) |

| Accuracy | High (often ±0.1–±2 g depending on product & scale) | Good, but dependent on fewer increments (±0.5–±5 g) |

| Best for | Small to medium pieces, high speed, consistent dosing | Large pieces, bulk portions, cost-sensitive lines |

| Fragile product handling | Good with gentle feeders and customized tooling | Often better for very large fragile items if gentle channels used |

| Footprint & complexity | Larger footprint, higher mechanical complexity | Smaller footprint possible, simpler mechanics |

| Typical investment range | Higher CAPEX, but lower giveaway and faster ROI on high-speed lines | Lower CAPEX for lower-speed applications |

Speed and accuracy — how they trade off

Multihead weighers achieve high speed by using many small weigh hoppers in parallel; the combination algorithm selects a set that matches the target. This approach reduces giveaway (overfilling) and keeps product variance low, which can improve long-term cost-efficiency. Combination weighers that use fewer channels may have lower top speeds and slightly larger weight increments, which can increase giveaway or require wider tolerances to maintain throughput. When very tight weight control is essential, multihead systems tend to outperform simpler combination setups.

Product suitability: which machine for which product?

Multihead weighers excel with free-flowing, piece-based, or small-size products (chips, nuts, candies, frozen peas) because distributed dosing and rapid combinations keep each pack consistent. Combination weighers or modular combination systems are often chosen for larger items (whole fruit, large frozen items), bulky solids, or products that do not distribute easily across many small hoppers. Fragile items can be handled by both types if fitted with soft-flow feeders, slow discharge options, or specially engineered infeed trays.

Footprint, hygiene and cleaning considerations

Multihead weighers often require larger footprints due to the circular head arrangement and multiple feeders. They also can be more involved to clean due to the number of small hoppers and moving parts; however, many modern multihead machines are designed for quick-change tooling and tool-less disassembly to meet hygienic standards. Combination weighers with fewer components can be quicker to clean and may be preferred in low-mix environments or lines that require frequent product changeovers.

Integration with packaging lines and automation

Both machine types integrate with vertical form-fill-seal (VFFS) machines, multi-lane baggers, and downstream checkweighers or metal detectors. Multihead weighers are commonly used in high-speed automated lines and often include advanced communication protocols (Ethernet/IP, Profinet) for Industry 4.0 connectivity. Combination weighers are easier to pair with low- to mid-speed packaging equipment and can be ideal for smaller plants or retrofit projects.

Total cost of ownership and maintenance

Initial cost for multihead weighers tends to be higher, but they can reduce product giveaway and increase throughput, delivering lower cost-per-pack on high-volume lines. Maintenance for multihead systems can be more intensive due to the number of moving parts, but reputable manufacturers design for serviceability and provide spare-part support and training. Combination weighers have lower CAPEX and can be less costly to repair, but higher giveaway or lower throughput may increase operating costs over time if production demand grows.

How Kenwei supports your weighing solution

Kenwei is a manufacturer specializing in multi-head weighers and related equipment. Based in Guangdong, China, Kenwei designs, manufactures and commissions automated weighing and packaging systems, including metal detectors, linear weighers and check weighers. For manufacturers deciding between a combination weigher and a multihead weigher, Kenwei offers consultative line layout, customization of feeders and hoppers, and integrated systems to match product characteristics and target throughput. Kenwei’s focus is on high speed, high precision machines and one-stop automated solutions to meet customized production needs.

Practical selection checklist: choose the right weigher

Use this checklist when deciding: product size and fragility, target packs per minute, tolerance/accuracy requirement, line integration (existing packer type), available floor space, washdown/hygiene needs, budget (CAPEX vs OPEX), and future growth plans. If your product is small, piece-like and you need high throughput with tight giveaway control, a multihead weigher is often the best choice. If your product is larger, the line runs moderate speeds, or you need a lower initial investment, a combination or modular weigher may be appropriate.

Real-world examples and ROI considerations

A confectionery plant replacing linear weigh belts with a multihead weigher often sees immediate increases in throughput and reduced giveaway, paying back the higher initial cost within months to a few years depending on volume. Conversely, a small bakery packaging whole loaves may prefer a simpler combination or linear system due to lower speeds and different handling needs. Always evaluate ROI based on your line speed, labor costs, product giveaway reduction and maintenance budgets.

Final recommendations

Both combination weigher and multihead weigher technologies have important roles in modern packaging. The decision should be driven by product characteristics, speed needs, accuracy requirements and total cost of ownership. Engage with suppliers who can run product trials and provide clear performance data under your line conditions. Kenwei offers product testing, customized tooling and integration support to help manufacturers select and commission the right weighing solution.

FAQ — Frequently asked questions

Q: Is a multihead weigher always more accurate than a combination weigher?

A: Not always, but multihead weighers generally achieve tighter weight control and lower giveaway on small-piece products because of more granular weighing increments and a higher number of heads.

Q: Which is better for fragile items?

A: Both types can handle fragile products if fitted with gentle feeders, low-impact chutes and customized tooling. For very fragile large items, combination or modular systems with fewer but softer channels can be preferable.

Q: How do I measure ROI?

A: Calculate ROI by comparing CAPEX, expected reduction in giveaway, increased throughput revenue, labor savings, and maintenance costs. High-volume lines often recover multihead investment faster due to lower giveaway and higher speed.

Q: Can Kenwei provide on-site trials?

A: Kenwei offers product testing and line simulations. Contact Kenwei through https://www.kenweigroup.com/ to arrange trials, engineering support and custom solutions.

Q: Are spare parts and service available worldwide?

A: Reputable manufacturers like Kenwei provide global service networks, spare parts and remote technical support. Confirm local service capabilities when planning purchase.

For personalized advice and to schedule product testing or a site consultation, visit Kenwei’s website or contact our sales team. Kenwei’s multi-head weighers and integrated packaging solutions help manufacturers optimize accuracy, speed and uptime while meeting hygiene and automation requirements.

Top 10 Tests to Validate Aluminum Foil Detection Performance

Energy-Efficient Food Grain Packing Machine Technologies: Practical Solutions for Lower Costs and Higher Throughput

The latest trends for metal detector food production

How a Combination Weigher Improves Packing Speed and Accuracy

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Standard Multihead Weigher with New Springless Actuator for Food Weighing Machine

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

14-Head High-Speed Springless Multihead Weigher for Accurate Weighing

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei