The Role of Combination Weighers in Intelligent Packaging Systems

Combination weighers, also known as multihead weighers, are essential in modern packaging automation. With high-precision weighing, intelligent algorithms, and strong adaptability, they improve efficiency, reduce costs, and support industries like food, pharmaceuticals, and chemicals.

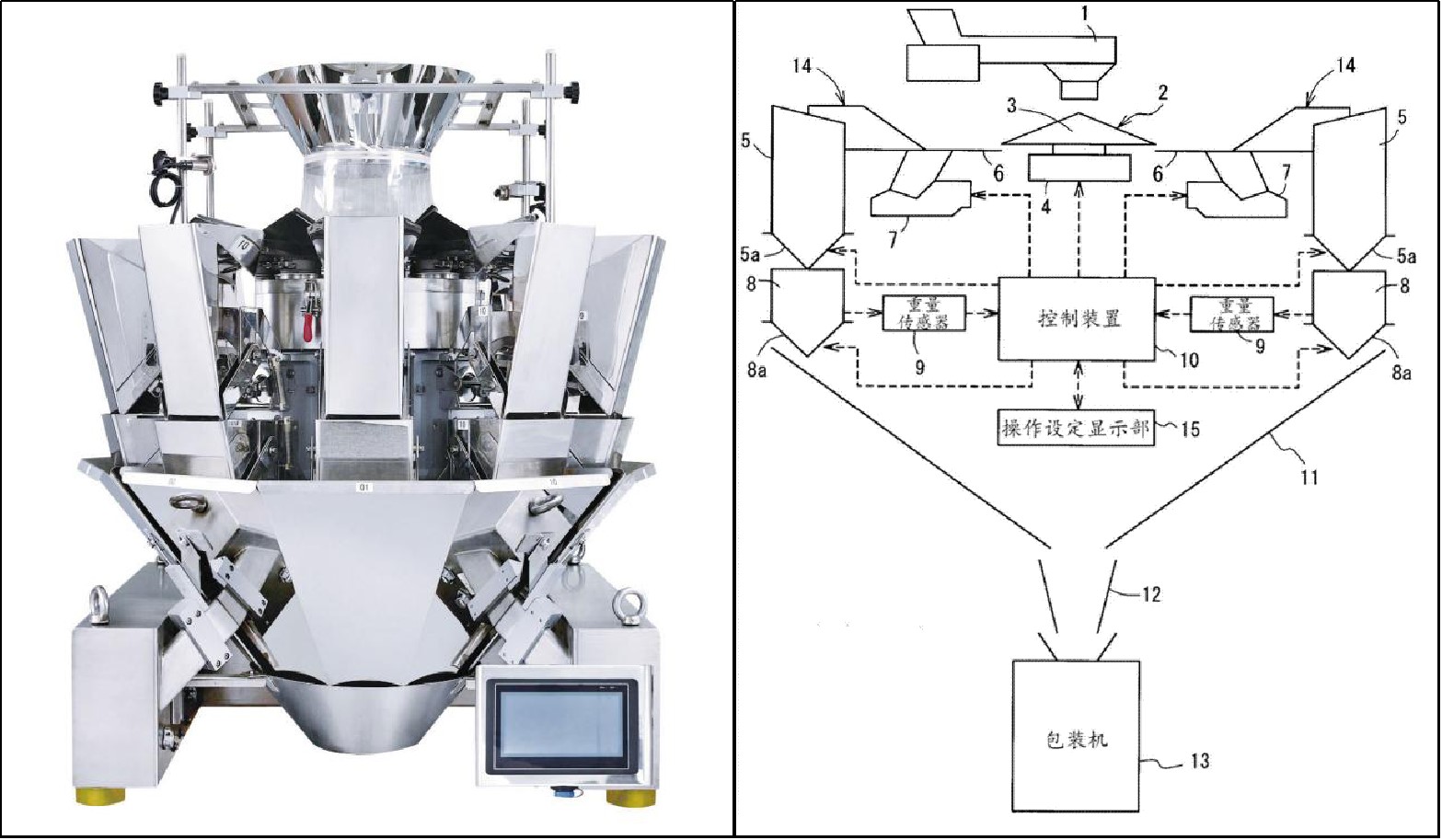

What is a Combination Weigher?

A combination weigher, also known as a multihead weigher, is a critical piece of equipment in industrial automation. Using 8 to 32 independent weighing units, it achieves ±0.1g precision through intelligent combination. Replacing traditional volumetric devices, it is now widely applied in the food, pharmaceutical, and chemical industries.

Core Structure and Advantages

Modern combination weighers adopt a three-layer design:

-

Upper Layer – Vibratory feeding trays evenly distribute materials.

-

Middle Layer – Weighing hoppers dynamically measure product weight.

-

Lower Layer – Material collection ensures precise discharge.

With high-precision sensors and integrated circuits, weighing speed exceeds 3 times per second. Unlike traditional platform scales with a 3–5% error rate, the combination weigher keeps errors within 0.3%. For example, a nut manufacturer reduced material loss by 12% and boosted packaging efficiency by 300% after adopting this system.

Five Major Technical Advantages

-

Intelligent Algorithm for Speed

Optimized algorithms and dynamic statistical correction enable speeds up to 200 packs per minute—3–4 times faster than traditional equipment. -

Modular Design

Quick assembly/disassembly in just 3 minutes, stainless steel parts, and flexible hopper sizes (1.6L, 2.5L, 3.0L). -

Error Prevention & Stability

Triple-verification system keeps error rates below 0.15% even after 200+ hours of continuous operation. -

Wide Material Adaptability

Capable of handling powders (≥0.5mm) to frozen products (250g), ensuring smooth processing of irregular shapes. -

Energy Efficiency

Intelligent sleep mode reduces standby energy consumption by 70%, lowering operating costs.

Industry Applications

-

Food Processing: Puffed snacks, nuts, grains, tea, coffee beans, pasta, and Chinese medicine.

-

Pharmaceutical & Healthcare: Ensures accurate dosing and safe packaging.

-

Daily Chemical & Electronics: Weighing and packing plastics, hardware, electronic parts, and components.

When integrated with a metal detector, defect interception rates exceed 98%, further ensuring product safety.

Purchasing and Maintenance Guide

When selecting a combination weigher, evaluate accuracy, speed, and certifications (CE, OIML). Leading brands such as Guangdong Kenwei Intellectualized Machinery Co., Ltd. are recognized for their precision and reliability, especially in the snack, fresh produce, meat, and pickled food industries.

For long-term performance, implement a three-tier maintenance system to reduce downtime. Additionally, consider warranty and technical support. For instance, Kenwei offers up to 2 years of extended warranty, making it a trusted choice for global manufacturers.

Future Development Trends

With the rise of Industry 4.0, combination weighers are evolving from simple weighing devices to intelligent production nodes. Key trends include:

-

AI Visual Recognition – Enhancing accuracy and adaptability.

-

Smart Integration with Multihead Weighers – Enabling seamless automation.

-

5G Connectivity – Remote diagnostics, real-time monitoring, and predictive maintenance.

Choosing the right intelligent multihead weigher solution is essential for businesses aiming to improve productivity and packaging quality.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei