Calibration Tips for Food Metal Detectors on Weighing Lines

- Calibration Tips for Food Metal Detectors on Weighing Lines

- Why calibration matters for a food metal detector

- Understand where the detector sits in the line

- Establish calibration and verification frequency

- Use appropriate test pieces and industry benchmarks

- Three-point verification across the aperture

- Maintain consistent product effect simulation

- Warm-up, environmental and operational stability

- Grounding and electromagnetic interference (EMI) control

- Documented calibration procedure and logs

- Automated versus manual calibration: pros and cons

- Calibration checklist: step-by-step

- When to adjust sensitivity and when to service

- Dealing with product effect and packaged products

- Training and operator competency

- Integrating calibration into quality systems

- Troubleshooting common calibration failures

- Choosing the right food metal detector technology

- About Kenwei and tailored solutions

- Case example: typical calibration schedule for a high-volume line

- Frequently Asked Questions (FAQ)

- How often should I perform sensitivity verification?

- What sizes of test pieces should I use?

- Should I calibrate with product or without?

- Can I calibrate during production?

- What if my detector fails verification consistently?

- Does Kenwei provide calibration support and training?

- How should I keep calibration records?

Calibration Tips for Food Metal Detectors on Weighing Lines

Why calibration matters for a food metal detector

Calibrating a food metal detector on a weighing line ensures contaminants are reliably detected while minimizing false rejects. Proper calibration protects consumers, preserves brand reputation, and keeps your production line compliant with retailer and regulatory requirements. For weighing lines that include multihead weighers and checkweighers, correct detector calibration also reduces unnecessary line downtime and product waste.

Understand where the detector sits in the line

Placement affects calibration. Common layouts place the food metal detector downstream of the multihead weigher and before packing or checkweigher stations. The upstream weigher can introduce mechanical vibration, metallic components, or product effect that alters detector response. When calibrating, simulate normal production conditions including product flow, conveyor speed, and load to ensure the detector behaves as it will in real operation.

Establish calibration and verification frequency

Industry best practice separates verification from full calibration. Verification (sensitivity checks with test pieces) should be performed at every shift start and after any product change. A formal calibration should be performed weekly or whenever verification fails, and a comprehensive service and certification should be completed annually by a qualified technician. More frequent checks are recommended for high-risk products or when retailer specs demand tighter tolerances.

Use appropriate test pieces and industry benchmarks

Select test pieces that represent realistic contaminants: ferrous, non-ferrous (e.g., aluminum), and austenitic stainless steel. Typical industry benchmarks used by many processors and retailers are roughly 1.5–2.0 mm ferrous, 2.0–2.5 mm non-ferrous, and 3.0 mm austenitic stainless spheres or pins. Use the smallest size required by your customer or regulatory standard as the verification target. Always document the test-piece type and size in calibration logs.

Three-point verification across the aperture

To ensure consistent sensitivity across the conveyor, perform verification in three positions: left edge, center, and right edge of the aperture. Some lines with wide conveyors should use five or more points. Record detection results at each position; a detector that only senses a test piece in the center but not the edges requires re-tuning or mechanical inspection for belt misalignment or foreign metal near the aperture.

Maintain consistent product effect simulation

Product effect—caused by moisture, salt, density, or packaging materials—can mask metallic signals. During calibration, run live product through the detector and perform verification with test pieces on top of the flowing product. For vacuum-packed, wet, or highly conductive products, additional sensitivity reduction or product effect compensation features may be necessary. Modern detectors include product rejection filters and auto-learn modes; validate these functions under actual production conditions.

Warm-up, environmental and operational stability

Allow the detector to warm up to normal operating temperature before performing calibration—typically 15–30 minutes after power-up. Temperature shifts and humidity changes can affect electronics. Keep conveyor speed, motor frequency drives, and line loads stable during calibration. If your line runs variable speeds, perform verification at representative speeds to confirm consistent detection.

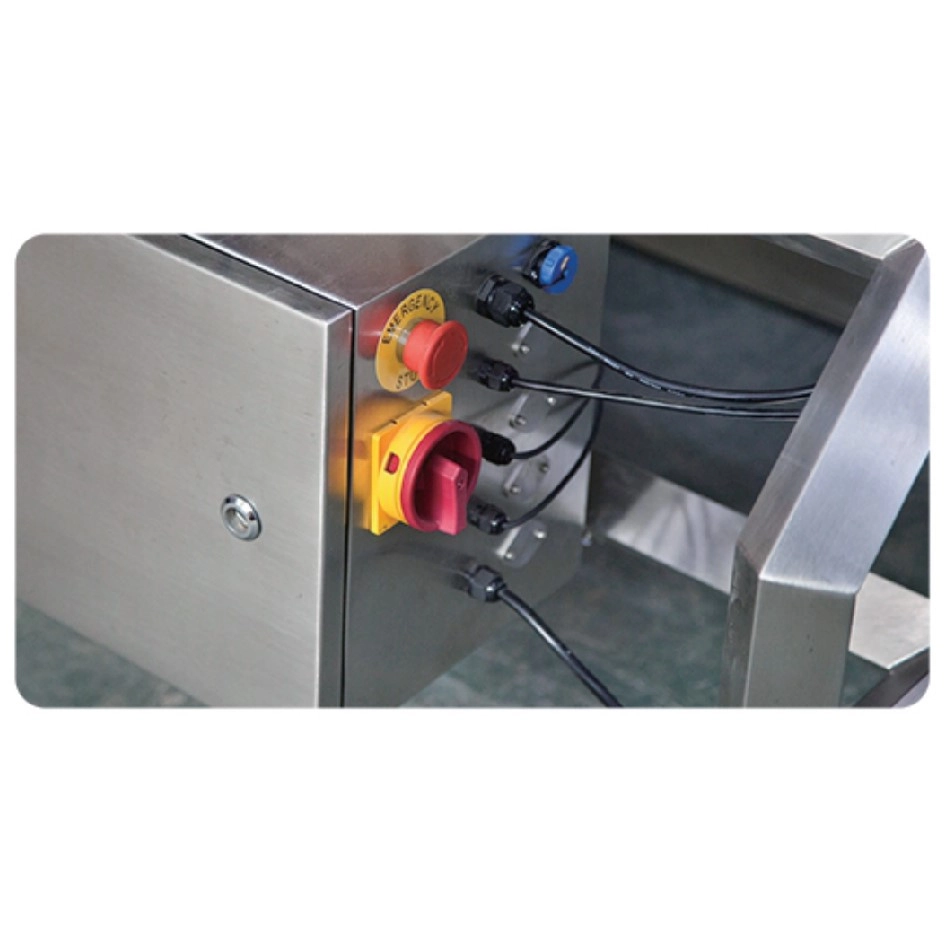

Grounding and electromagnetic interference (EMI) control

Poor grounding, nearby radio equipment, welding, or high-power motors can introduce EMI that degrades detector performance. Ensure the detector frame is properly grounded and isolated from large metal structures that might create earth loops. Use shielded cabling where recommended, maintain a tidy electrical layout, and, when possible, avoid routing power cables parallel to detector cables. If EMI is suspected, perform calibration tests at different times and locations to identify intermittent interference sources.

Documented calibration procedure and logs

Maintain written calibration SOPs that list required test pieces, positions, environmental conditions, and acceptance criteria. Log every verification and calibration action: who performed it, time, test-piece sizes and materials, results for each aperture position, and corrective actions taken. These records support traceability for audits and can be vital when investigating field escapes or customer complaints.

Automated versus manual calibration: pros and cons

Automated calibration systems reduce human error and improve repeatability, while manual calibration is flexible and cost-effective for small operations. Below is a comparison to guide your choice.

| Feature | Manual Calibration | Automated Calibration |

|---|---|---|

| Consistency | Depends on operator skill | High repeatability |

| Speed | Slower; requires stopping or slowing line | Faster; can run during production |

| Cost | Lower initial cost | Higher initial cost but lower long-term labor |

| Audit Trail | Requires manual logging | Automatic electronic logs and trends |

| Best for | Low-volume or variable lines | High-volume, multi-line facilities |

Calibration checklist: step-by-step

Use this short checklist each verification cycle: 1) Warm up detector 15–30 minutes. 2) Verify conveyor speed and product flow match production. 3) Confirm grounding and EM shielding. 4) Use correct test-piece sizes and materials. 5) Place test piece in left, center, right positions on product. 6) Record detection responses and times. 7) Re-tune sensitivity if failures occur and repeat verification. 8) Log results and corrective actions.

When to adjust sensitivity and when to service

If verification fails on one position but not others, first inspect the conveyor for metallic wear particles, belt misalignment, or nearby loose components. Re-check grounding and remove possible external metal sources. If the detector shows inconsistent behavior across time or temperature or cannot be tuned to meet verification targets, schedule a service visit. Annual preventive maintenance by a certified technician ensures calibration integrity and component health.

Dealing with product effect and packaged products

High-moisture or salty products create stronger product signals that may mask small metal contaminants. For packaged products, material layers and packaging metallization (e.g., foil) also increase product effect. Use product learn modes when available, increase aperture spacing if practical, or add a secondary inspection stage such as x-ray for dense or high-product-effect items. Always validate tolerance against your customer’s acceptance criteria.

Training and operator competency

Calibration is only as good as the people who carry it out. Provide structured training that covers detector basics, test-piece handling, SOPs, and troubleshooting. Use competency tests and refresher training every 6–12 months. Well-trained operators reduce false rejections and ensure calibration integrity.

Integrating calibration into quality systems

Include detector verification in HACCP plans and your quality management system. Tie calibration logs to batch records and corrective action reports. When a contamination incident occurs, recorded calibration data can accelerate root-cause analysis and support recall decisions or defence in supply-chain disputes.

Troubleshooting common calibration failures

Frequent issues include failed detection at edges (check belt alignment), intermittent detections (inspect for EMI or grounding problems), and persistent inability to reach sensitivity targets (check for large nearby metal masses or excessive product effect). Re-testing with a known good detector or swapping conveyor modules can isolate mechanical from electrical causes.

Choosing the right food metal detector technology

Metal detectors for weighing lines vary: single-frequency, multi-frequency, and combined technologies with checkweighers or x-ray systems. Multi-frequency detectors handle a wider range of product effects and often offer better sensitivity for difficult products. For high-speed multihead weigher lines, choose detectors with proven throughput and integrated reject systems to minimize false accepts and maintain production efficiency.

About Kenwei and tailored solutions

Kenwei is a powerful manufacturer of multi-head weighers committed to developing and producing metal detectors, multi-head weighers, linear weighers, and check weighers. With a focus on high speed and high precision, Kenwei provides one-stop automated weighing and packaging solutions and supports custom requirements. Located in Fusha High-tech Industrial Park, Zhongshan, Guangdong, Kenwei offers design, manufacturing, installation, training and after-sales service. Learn more at https://www.kenweigroup.com/. For weighing-line metal detection needs, Kenwei can supply integrated systems and calibration support tailored to your product and throughput.

Case example: typical calibration schedule for a high-volume line

Example schedule used by many high-volume food processors: Shift start verification with three-position test pieces (every 8 hours); product-change full verification; weekly full calibration (recorded and signed); and annual third-party certification and service. This layered approach balances safety with line uptime.

Frequently Asked Questions (FAQ)

How often should I perform sensitivity verification?

Perform sensitivity verification at every shift start and after any product change. Increase frequency for high-risk products or if your customers specify tighter controls.

What sizes of test pieces should I use?

Use the smallest sizes required by customers or regulations. Typical industry targets are ~1.5–2.0 mm ferrous, 2.0–2.5 mm non-ferrous, and ~3.0 mm austenitic stainless. Always document the sizes and materials used for verification.

Should I calibrate with product or without?

Always verify with the product flowing: product effect can mask contaminants. Calibrating in air only can give misleading sensitivity levels for real production conditions.

Can I calibrate during production?

Automated calibration solutions allow in-line verification without stopping the line. For manual checks, a brief pause or slow-down may be needed to safely place test pieces and ensure consistent readings.

What if my detector fails verification consistently?

Check grounding, belt alignment, nearby metal, and EMI sources first. If the issue persists after basic checks, schedule a service visit for in-depth diagnostics and possible component replacement.

Does Kenwei provide calibration support and training?

Yes. Kenwei supplies integrated weighing and inspection systems and offers installation, operator training, technical support and after-sales service. Contact Kenwei through their website for tailored calibration and support packages.

How should I keep calibration records?

Use either electronic logs from automated systems or paper logs for manual checks. Records should include date/time, operator, product ID, test-piece types and sizes, positions tested, results, and corrective actions. Retain records per your quality system and audit requirements.

Top 10 Installation Tips for Food Industry Metal Detectors

Selecting Good Metal Detectors for High-Speed Production Lines

Top Food Metal Detector Models for Packaging Lines 2025

The B2B Buyer’s Guide to combination weigher packing line

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

High Sensitivity Horizontal Metal Detector for Food and Pharmaceutical Industries

The Horizontal Metal Detector Series is ideal for detecting both ferrous and non-ferrous metals in food, pharmaceutical, chemical, textile, and rubber products. Equipped with a 7" industrial touch screen and supporting 32 languages, it features high sensitivity, digital signal processing, and intelligent algorithms for stable, precise detection. With stainless steel waterproof construction and multiple rejection options, it's perfect for HACCP and GMP compliance.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei