Buying Guide: Choosing the Right Food Grain Packing Machine — Kenwei Expert Guide

- Buying Guide: Choosing the Right Food Grain Packing Machine

- Introduction — Why this buying guide matters for food grain packing

- Understanding user intent — what buyers are really looking for

- Machine types and when to choose each — multihead weighers, linear weighers, and vertical form-fill-seal (VFFS)

- Key selection criteria — capacity, accuracy, and product handling

- Packaging format and materials — bags, pouches, and materials compatibility

- Sanitation, food safety, and regulatory compliance

- Automation and integration — building a complete line

- Serviceability, spare parts and total cost of ownership (TCO)

- Performance metrics to request and validate before purchase

- Customization and optional features that add value

- Why Kenwei — strengths and offerings for grain packers

- Budget planning and ROI considerations

- How to run an effective vendor evaluation and pilot test

- Conclusion — making the right purchase decision

- Final checklist before signing the purchase order

- Frequently Asked Questions

Buying Guide: Choosing the Right Food Grain Packing Machine

Introduction — Why this buying guide matters for food grain packing

Searching for Buying Guide: Choosing the Right Food Grain Packing Machine usually means you are evaluating solutions to pack rice, wheat, pulses, oats or blended grains reliably and profitably. This guide walks through the decision factors buyers commonly need: machine type, throughput and accuracy, product characteristics, packaging format, sanitation and compliance, integration with upstream/downstream equipment, total cost of ownership, and after-sales support. We also explain why Kenwei, as an experienced multihead weigher manufacturer, is a solid partner for automated weighing and packing solutions.

Understanding user intent — what buyers are really looking for

Buyers want a machine that meets production targets, maintains weight accuracy (to control giveaway), handles product-specific challenges (fragility, dust, size variation), and integrates with existing packing lines. They look for clear ROI, reliable service, customization options, and compliance with food safety standards. This guide targets those commercial needs and shows how to choose equipment to achieve them.

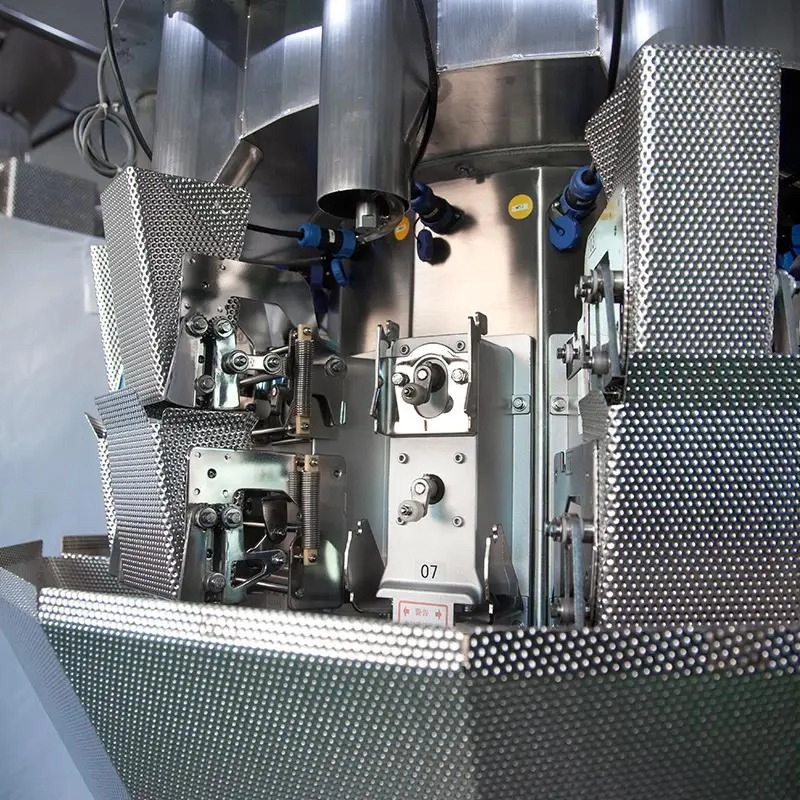

Machine types and when to choose each — multihead weighers, linear weighers, and vertical form-fill-seal (VFFS)

Many projects require a combination of machines. Below is a concise comparison to match common grain-packing scenarios:

| Machine Type | Best for | Strengths | Limitations |

|---|---|---|---|

| Multihead Weigher | High-speed granular products (rice, pulses, seeds) | High throughput, excellent accuracy, minimal giveaway, flexible portioning | Higher upfront cost; requires consistent feed and proper hoppers |

| Linear Weigher | Low-to-medium speed, sticky or fragile products | Simpler mechanics, easier cleaning for some products, lower cost for small lines | Lower speed and less accurate for fine weights versus multihead |

| VFFS (vertical form-fill-seal) | Bag-making and sealing for flexible packaging | Compact, cost-effective for variable bag lengths, integrates with weighers | Sealing quality depends on film and machine; requires proper integration |

Key selection criteria — capacity, accuracy, and product handling

When selecting a food grain packing machine, focus on three pillars: throughput (packs per minute or kg/hour), accuracy (target weight tolerance), and product-specific handling (grain size, broken kernels, dust). For granular grains, multihead weighers are typically chosen when accuracy and speed are priorities because they combine multiple weigh heads to achieve a correct target weight with minimal giveaway. Suppliers often quote speed in packs per minute (ppm) and standard deviations (SD) for accuracy — ask for test reports with your product.

Packaging format and materials — bags, pouches, and materials compatibility

Decide the packaging format early. Are you filling pre-made bags, pillow pouches, gusseted bags, or making bags from rollstock? This affects whether you need VFFS integration or a pick-and-place solution. Also check film compatibility (layflat PE, laminated films) since sealing temperature and nip pressure change with material. Machines designed for food applications should allow quick changeovers and parameter presets for different bag sizes.

Sanitation, food safety, and regulatory compliance

Food grain packing must satisfy hygiene and traceability requirements. Look for stainless steel construction (typically 304 SS for food contact), hygienic hopper designs to reduce harbor points, IP-rated electrical enclosures, and easy-to-clean surfaces. Ensure the manufacturer supports documentation for compliance with local regulations and can provide materials certificates and traceability protocols. Metal detection and checkweighing integration are commonly required to meet retailer and export standards.

Automation and integration — building a complete line

Packaging projects rarely involve a single machine. Plan for upstream feeding (bucket elevators, screw conveyors, vibratory feeders), infeed distribution for the weigher, downstream sealing and conveyor systems, metal detectors, and checkweighers. Choose machines with open communication protocols (Ethernet/IP, Modbus, ProfiNet) or proven PLC integration to simplify line control and data collection for industry 4.0 applications.

Serviceability, spare parts and total cost of ownership (TCO)

Low downtime is critical. Evaluate the supplier's spare parts availability, local service presence, and training offerings. TCO includes energy use, maintenance labor, spare parts, and product giveaway. A more accurate machine (smaller giveaway) can deliver faster payback even if initial spend is higher. Request references or case studies showing realized ROI for similar grain products.

Performance metrics to request and validate before purchase

Ask vendors for data measured with your product: throughput (ppm), weight accuracy (mean deviation and SD), average giveaway per 1,000 packs, and cycle times for changeovers. Insist on Factory Acceptance Tests (FAT) or on-site trials to confirm performance. Typical multihead weighers offer highly repeatable results for granular products due to combinatorial weighing logic, but real-world performance depends on feed consistency and correct setup.

Customization and optional features that add value

Look for optional features that address your operational needs: dust extraction, product spreaders, anti-static measures, servo-driven feed pans for delicate grains, quick-change hoppers, product recipe storage, and HACCP-ready traceability logging. These reduce waste, speed changeovers, and improve food safety, which are important to buyers searching for Buying Guide: Choosing the Right Food Grain Packing Machine with .

Why Kenwei — strengths and offerings for grain packers

Kenwei is a manufacturer specializing in multihead weighers, metal detectors, linear weighers, and checkweighers. The company provides one-stop automated weighing and packaging systems aimed at high speed and high precision. Kenwei's capabilities include custom system design, manufacturing, installation, commissioning, operator training, and after-sales service from its base in Guangdong's Fusha High-tech Industrial Park. For grain processors needing scalable, integrated solutions, Kenwei can test your product on its equipment and provide validated performance data to support purchasing decisions.

Budget planning and ROI considerations

Plan budget around three buckets: equipment cost, integration/customization, and lifecycle costs (energy, parts, labor). Use conservative estimates of increased throughput and reduced giveaway to model payback. Many processors see payback when giveaway reduction and labor savings offset the purchase within a few years; obtain model-specific case studies from suppliers to build a realistic ROI forecast.

How to run an effective vendor evaluation and pilot test

Shortlist vendors and request: product-specific test reports, FAT with your grain, site references, spare parts lead times, and training plans. During on-site trials, measure real throughput, weight accuracy, and ease of changeover. Verify communication and mechanical interfaces for a smoother integration into your factory line.

Conclusion — making the right purchase decision

Final checklist before signing the purchase order

Before purchase, confirm the following: machine performance validated with your grain, total solution including feeders and downstream equipment, clear service and spare parts agreement, staff training included, warranty and acceptance criteria defined, and data connectivity for production tracking. Choosing the right food grain packing machine requires balancing speed, accuracy, hygiene, and TCO — and engaging manufacturers who can demonstrate real-world results.

Frequently Asked Questions

What is the most accurate machine for packing rice and pulses?A: For granular products like rice and pulses, multihead weighers are generally the most accurate option because they use combinatorial weighing across multiple heads to match target weights with minimal giveaway. Accuracy depends on the specific model and feed consistency; request test data with your product.

How do I estimate the throughput needed?A: Calculate your desired production in packs per minute (ppm) or kilograms per hour, then include downtime, changeovers, and growth margin. Ask vendors to supply performance figures for your product and include them in acceptance tests.

Can metal detectors and checkweighers be integrated with weighers?A: Yes. Metal detectors and checkweighers are commonly integrated downstream of weighing equipment. Choose suppliers who provide integrated solutions and support communication protocols for synchronized control and data logging.

What hygiene features should I prioritize for grain packing?A: Prioritize stainless steel food-contact parts, easily removable hoppers and pans, enclosed dust control, and designs that minimize crevices where product can collect. Also ensure electrical components are IP-rated and accessible for cleaning.

How important is after-sales support and spare parts availability?A: Very important. Quick access to spare parts and local service reduces downtime. Verify spare parts lead times and whether local technicians are available for emergency repairs and scheduled maintenance.

Does Kenwei offer customized solutions for different bag formats?A: Kenwei provides one-stop automated weighing and packaging solutions, including customization for different bag types, integration with VFFS or pre-made bag systems, and tailored feeding systems. Contact Kenwei with product samples for performance testing and a tailored solution.

The B2B Buyer’s Guide to automatic check weigher machine

Spare Parts and Backup Planning for 14-Head Multihead Weigher

Integrating backup systems with 14 head multihead weighers

The packing food machine Cost Guide

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei