Multihead Weigher Machines: Precision, Speed, and Efficiency in Modern Packaging

Multihead weigher packing machines have revolutionized industrial weighing by combining high precision, speed, and efficiency. Widely applied in food, pharmaceuticals, and hardware sectors, they minimize product waste, optimize production, and ensure consistent packaging quality across industries.

Precision is no longer just a supporting requirement—it is a critical factor for success in today’s fast-paced industrial operations. From food packaging lines to pharmaceutical production, accurate weighing directly impacts product quality, efficiency, and profitability. The multihead weigher machine has emerged as a breakthrough solution, delivering unmatched accuracy, consistency, and speed. Today, these automatic weighing and packing machines are widely used in food packaging, pharmaceuticals, and hardware manufacturing to meet strict industry standards while maximizing operational efficiency.

Historical Development of Weighing Systems

The history of weighing technology reflects a continuous pursuit of speed and accuracy. Early industrial scales relied on single-head motors that, while functional, could not meet growing production demands. These systems were often slow, inconsistent, and unsuitable for large-scale operations.

The 1970s saw the introduction of multihead weighers, marking a revolution in weighing systems. By integrating multiple weighing heads working in parallel, these machines delivered higher precision, faster throughput, and greater consistency—solving challenges of accuracy, speed, and product giveaway.

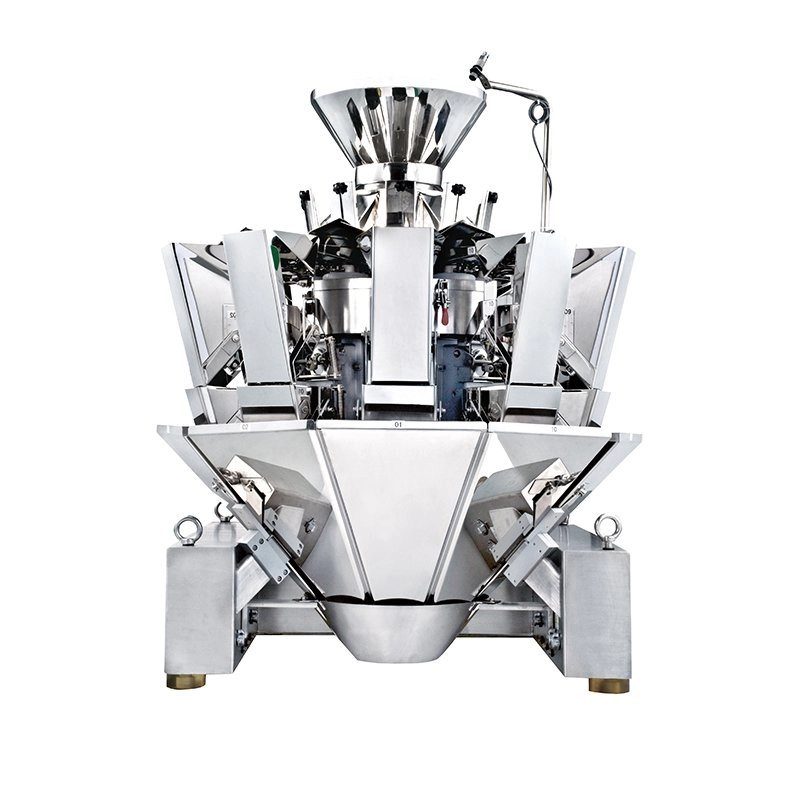

Anatomy of a Multihead Weigher

A multihead weigher packing machine is a combination of highly engineered components working in harmony:

-

Hoppers: Main hoppers store bulk products, weigh hoppers measure product weight, and memory hoppers temporarily store items to optimize combinations.

-

Load Cells: Sensitive sensors that convert product weight into electrical signals for precision.

-

Dispersion Table: Vibrating feeders ensure even product distribution to weighing heads.

-

Control System: Advanced microprocessors calculate the best weight combinations in real time.

This systematic design ensures uniformity, reliability, and top-level efficiency in every operation.

How Multihead Weighers Work

The operating principle follows a structured, automated process:

-

Product Loading – Products are placed on the dispersion table and evenly distributed.

-

Weighing Heads – Each head measures the product weight with a load cell.

-

Combination Algorithm – The control system calculates the best combination closest to the target weight.

-

Optimal Selection – The system selects the most precise combination with minimal overfill.

-

Product Release – The accurate batch is released into the automatic packing machine.

This cycle occurs in milliseconds, enabling hundreds of weight checks per minute with superior accuracy.

Key Advantages of Multihead Weighing Technology

-

Accuracy & Consistency: Reduces human error and prevents product giveaway, saving costs.

-

Speed & Efficiency: Handles hundreds of weight checks per minute, perfectly matching high-speed packaging lines.

-

Versatility: Suitable for snacks, sticky goods, fragile products, and even hardware.

-

Cost-Effectiveness: Minimizes material waste and delivers high ROI over time.

Challenges in Multihead Weigher Operations

While highly efficient, operators face some challenges:

-

Managing sticky or irregularly shaped products.

-

Regular calibration and maintenance of load cells and hoppers.

-

Need for skilled operators to handle control systems.

-

High upfront investment, though offset by long-term benefits.

Future Trends and Innovations

The next generation of multihead weighers will incorporate smart manufacturing features such as:

-

AI & IoT Integration for predictive maintenance and real-time monitoring.

-

Advanced Algorithms for higher precision with variable products.

-

Sustainable Design to reduce energy and material consumption.

-

Full Automation for seamless packaging and production lines.

Applications Across Industries

-

Food Industry: Ideal for weighing snacks, frozen goods, confectionery, and produce.

-

Pharmaceuticals: Ensures precise dosage of pills, powders, and capsules.

-

Non-Food Products: Used in hardware packaging for bolts, screws, and small parts.

Conclusion

The multihead weigher machine represents a milestone in weighing and packaging technology, delivering precision, speed, and operational efficiency that older systems cannot match. By combining advanced algorithms with robust engineering, these machines minimize waste and maximize productivity. As industries continue to demand higher standards and faster output, food packaging equipment like multihead weighers will remain at the core of modern manufacturing.

If you are looking for a reliable multihead weigher manufacturer, contact Kenwei today.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

Discover the Kenwei Leak Proof Multi Head Combination Weigher for Small Particle & Powder. This advanced multihead weigher machine ensures high-precision weighing, leak-proof performance, and efficiency. Ideal for various industries needing accurate combination weigher solutions.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei