Top 10 Installation Tips for Food Industry Metal Detectors

- Pre-installation Planning and Site Considerations

- 1. Conduct a full site and process survey

- 2. Choose the right location on the line

- 3. Environmental controls and hygiene zones

- Mechanical and Electrical Installation Best Practices

- 4. Integrate with conveyor mechanics and product presentation

- 5. Grounding, cable routing, and EMI management

- 6. Power supply and surge protection

- Calibration, Testing and Validation

- 7. Use product-specific calibration and product effect compensation

- 8. Establish testing frequency and validation protocol

- 9. Use standardized test pieces and traceable procedures

- Maintenance, Troubleshooting and Training

- 10. Implement routine maintenance and quick-check routines

- 11. Troubleshoot common issues with a systematic approach

- 12. Train operators and maintain documentation

- Practical Tips Specific to Aluminum Foil-Packaged Products

- 13. Understand foil's effect and use foil-aware detectors

- 14. Optimize conveyor aperture size and product spacing

- 15. Combine technologies for high-risk products

- Quick Reference: Sensitivity Guidance and Typical Detectable Sizes

- Standards, References and Further Reading

- FAQs

- Q1: Why does aluminum foil make metal detection harder?

- Q2: How often should I validate my metal detector?

- Q3: Can a metal detector find non-metal contaminants?

- Q4: Is the 2415 Metal Detector suitable for all foil-packaged products?

- Q5: What documentation should I keep for audits?

- Contact & Product Information

Installing a metal detector for the food industry requires careful planning across site layout, electromagnetic considerations, conveyor integration, sensitivity calibration, and ongoing validation. Proper installation reduces false rejects, maintains detection performance—especially for challenging packaging like aluminum foil—and helps meet food safety standards such as ISO 22000 and regulatory expectations from agencies like the FDA. Below are practical, prioritized installation tips to maximize uptime, detection accuracy, and regulatory compliance for systems designed to detect metallic contaminants in food products.

Pre-installation Planning and Site Considerations

1. Conduct a full site and process survey

Before selecting or installing any metal detector for food industry use, perform a detailed site survey of the production line. Map conveyor layouts, product flow direction, nearby machinery (motors, VFDs, ovens), and potential sources of electromagnetic interference (EMI). Early identification of interference sources helps avoid placement that would degrade sensitivity and increases the chance of a clean installation.

2. Choose the right location on the line

Position the metal detector after processes that could introduce metal contamination (e.g., grinding, cutting, filling), but before packaging steps where product shape or packaging will complicate detection. For products in aluminum foil packaging, place the unit where the product headspace and orientation are most consistent—this helps the detector compensate for product effect and packaging noise.

3. Environmental controls and hygiene zones

Install metal detectors in compliance with hygiene zoning: washdown-capable detectors in wet zones and IP-rated enclosures where necessary. Verify ambient temperature and humidity limits for the selected metal detector and ensure that cleaning protocols won't damage sensors or electronics. Proper environmental protection preserves long-term sensitivity and reduces downtime for repairs.

Mechanical and Electrical Installation Best Practices

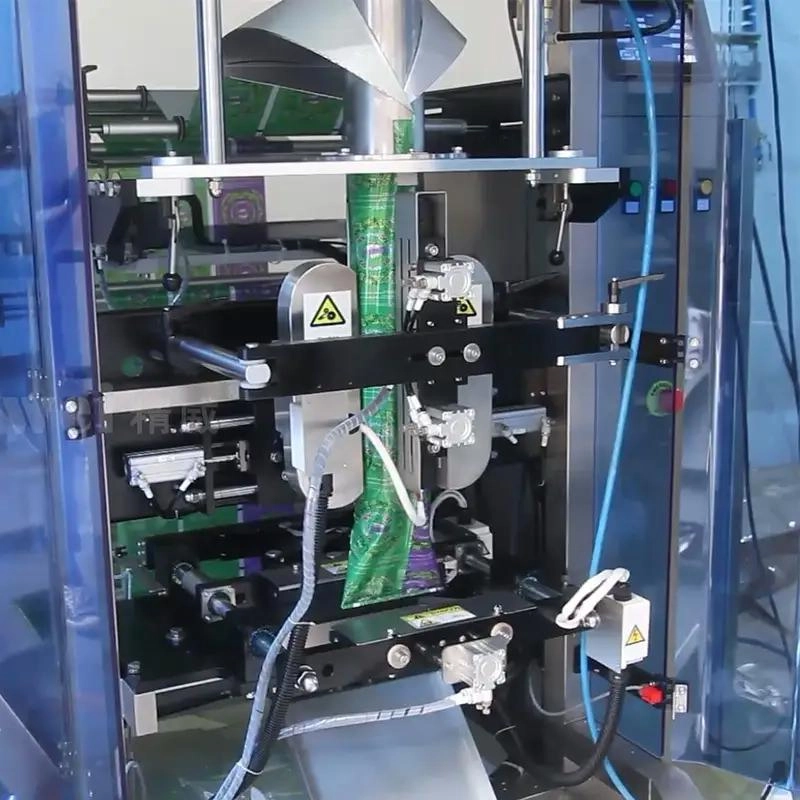

4. Integrate with conveyor mechanics and product presentation

Mechanical integration affects both detection and rejection accuracy. Maintain steady, centered product presentation through the inspection aperture. Use center rails, guides or flights to ensure consistent orientation, especially for small items such as coffee bags, chocolates, or small snack packs. For belt conveyors, ensure the belt is non-metallic around the aperture and free of metal fasteners that could create background noise.

5. Grounding, cable routing, and EMI management

Proper grounding and cable routing are vital. Run signal and power cables separately from heavy motor or VFD cables. Ground the detector frame to the plant ground to minimize interference. If nearby equipment creates EMI, use grounded shielding or relocate the detector. These steps reduce false trips and protect detection sensitivity.

6. Power supply and surge protection

Provide stable power with HVAC-friendly surge protection and isolation where appropriate. Voltage fluctuations and noisy power can affect detector electronics and sensor stability. Consider adding an uninterruptible power supply (UPS) to prevent reboots during critical runs and to allow graceful shutdowns when power quality is poor.

Calibration, Testing and Validation

7. Use product-specific calibration and product effect compensation

Different products and packaging cause varying 'product effect'—the detector signal produced by the product itself. For aluminum foil-packaged goods, a standard metal detector may be desensitized by the packaging. The Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection is engineered to handle this:

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

During calibration, create and store product profiles for each SKU: use representative samples, run known-size test pieces (ferrous, non-ferrous, and stainless), and adjust sensitivity to find the best balance between detection performance and false reject rate. Where possible, use automatic product compensation features to maintain consistent sensitivity across product variations.

8. Establish testing frequency and validation protocol

Validate performance using documented test pieces at a defined frequency (e.g., start of shift, after product changeover, after maintenance). Record results in a log to demonstrate ongoing control. Regulatory frameworks and food safety best practices expect documented validation—see ISO 22000 for food safety management system expectations (ISO 22000).

9. Use standardized test pieces and traceable procedures

Adopt test pieces and procedures aligned with recognized guidance. The FDA and other agencies stress prevention and hazard analysis; ensuring traceable validation helps during audits. Use three-material testing (ferrous, non-ferrous, stainless) and include tests with the product in its primary packaging—especially important when packaging contains aluminum foil that can mask or alter signals. For high-risk lines, increase test frequency and keep sample records.

Maintenance, Troubleshooting and Training

10. Implement routine maintenance and quick-check routines

Create a routine maintenance schedule: clean the aperture and conveyor area, verify belt tension and alignment, check cable connectors, and review alarm logs. Quick-check procedures at every shift (visual inspection + test piece) minimize risk of undetected failures and support rapid corrective action when needed.

11. Troubleshoot common issues with a systematic approach

Common installation/operation issues include false rejects, missed detections, and erratic alarms. Troubleshooting steps:- Verify ground and cable routing.- Re-run calibration with a known-good product profile.- Check conveyor mechanical alignment and product presentation.- Inspect for nearby intermittent EMI sources (e.g., motors that cycle on/off).Document each step so recurring problems can be escalated to engineering or vendor support for deeper analysis.

12. Train operators and maintain documentation

Human factors are frequently the weakest link. Train staff on product changeovers, product profiles, quick-checks, alarm response, and how to record validation logs. Keep easy-to-follow SOPs near the line, and ensure vendor contact information for rapid escalation. Well-trained operators reduce downtime and maintain consistent metal detection performance.

Practical Tips Specific to Aluminum Foil-Packaged Products

13. Understand foil's effect and use foil-aware detectors

Aluminum foil causes eddy currents and can mask or alter metal detector signals. Choose detectors with foil compensation or use the model specifically engineered for foil packaging, like the 2415 Metal Detector for Aluminum Foil. These systems apply algorithms and high-sensitivity sensors to filter foil signals while maintaining detection of magnetic contaminants.

14. Optimize conveyor aperture size and product spacing

For small foil pouches, tighter aperture sizes reduce detector coil area and improve signal-to-noise ratio. Keep consistent spacing to avoid two products in the aperture simultaneously, which can create a larger product effect and unpredictable signals. If your production speed varies, consider multi-scan modes or reject verification sensors downstream.

15. Combine technologies for high-risk products

In critical applications (e.g., products for immunocompromised consumers, baby food), consider pairing metal detection with complementary methods such as X-ray for dense contaminants or vision systems for packaging integrity. Each technology has strengths: metal detectors are excellent for small metallic pieces, while X-rays can detect glass, stone, and high-density non-metallic contaminants. For guidance on layered food safety systems, see Codex Alimentarius and FSMS principles (Codex Alimentarius).

Quick Reference: Sensitivity Guidance and Typical Detectable Sizes

The table below provides example sensitivity guidance. These are typical ranges—actual detectability depends on the product matrix, packaging, product orientation, and detector model. Use as a starting point only and always validate with test pieces in-line.

| Material | Recommended Sensitivity Range (typical) | Typical Minimum Detectable Size (mm) | Notes |

|---|---|---|---|

| Ferrous | High | 0.5 - 1.5 mm | Best detected; use conservative setting in noisy environments |

| Non-ferrous (copper/aluminum) | Medium | 1.0 - 3.0 mm | Aluminum in packaging can mask; use foil-aware detector |

| Stainless (austenitic) | Lower | 2.0 - 6.0 mm | Harder to detect; validate with representative test pieces |

Standards, References and Further Reading

Installations should align with food safety management expectations and documented validation. Useful, authoritative references include:

- ISO 22000 — Food safety management systems (ISO)

- U.S. Food and Drug Administration — Food Safety (FDA)

- Codex Alimentarius — FAO/WHO (international food standards)

- Metal detector — overview and technology (Wikipedia)

FAQs

Q1: Why does aluminum foil make metal detection harder?

A: Aluminum foil induces eddy currents and changes the electromagnetic field used by metal detectors, creating a product effect that can mask metal contaminants. Specialized detectors and product compensation techniques are used to filter foil signals and retain contaminant sensitivity.

Q2: How often should I validate my metal detector?

A: Minimum validation is recommended at shift start, after product changeovers, and after any maintenance or environmental change. High-risk lines may require more frequent checks. Always document test results to meet audit requirements and food safety management system expectations.

Q3: Can a metal detector find non-metal contaminants?

A: No. Metal detectors are designed to detect metallic contaminants only. Use complementary technologies such as X-ray systems for non-metallic hazards like glass, stone, or dense plastics.

Q4: Is the 2415 Metal Detector suitable for all foil-packaged products?

A: The 2415 Metal Detector for Aluminum Foil is optimized for foil-packaged items including coffee bags, peanuts, dried meats, and chocolates. Its adjustable aperture and high-sensitivity sensors make it versatile, but final suitability depends on product size, speed, and packaging. Validate in your line with representative samples.

Q5: What documentation should I keep for audits?

A: Maintain installation records, product profiles, validation logs (test piece results), maintenance records, and SOPs for operator checks. These records demonstrate control and support compliance with standards like ISO 22000 and regulatory expectations from authorities such as the FDA.

Contact & Product Information

If you need tailored advice for your line or want to see the Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection in action, contact our technical sales team or view the product page for specifications and integration support. For a consultation, visit our Contact Page or view the product details at Metal Detector 2415 - Product Page.

Note: This guide provides practical best practices. Always validate with your product and follow local regulatory requirements and guidance.

Selecting Materials and Conveyor Design to Optimize Detection

Choosing Weigher Channels and Hoppers 2026

Combination Weigher Safety Standards and Compliance 2026

Energy, Maintenance, and Uptime: Procurement Guide to VFFS

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Cooperation Process

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei