Compliance Guide: Good Metal Detectors and Food Standards

- Compliance Guide: Good Metal Detectors and Food Standards

- Why good metal detectors are a foundation of food safety

- Regulatory landscape: What food processors must know about metal detection

- Key standards and expectations for using good metal detectors

- How to choose good metal detectors for food production

- Key selection criteria to meet compliance and operational goals

- G5020 Food Metal Detector Manufacturer for Rejecting Defective Products

- Product overview and why it's a strong choice among good metal detectors

- Installation and hygienic design: reduce contamination risk

- Best practices for installing good metal detectors on food lines

- Validation, testing and verification of good metal detectors

- How to validate sensitivity and document compliance

- Comparing detector performance: a practical table

- Sensitivity, hygiene and operational factors

- Operational strategies to minimize false rejects and maximize uptime

- Calibration, product setup and training tips

- Integration with multihead weighers and production lines

- Why coordination matters for compliance and yield

- Case examples: real-world advantages of using compliant detectors

- Practical outcomes from implementing good metal detectors

- Brand advantages and why G5020 stands out among good metal detectors

- How the G5020 aligns with compliance, operations and ROI

- Maintenance checklist for long-term compliance

- Daily, weekly and monthly tasks to keep good metal detectors audit-ready

- FAQ — Frequently Asked Questions about good metal detectors and food standards

- Q: How often should metal detectors be tested?

- Q: Can metal detectors find all types of metal?

- Q: What documentation do auditors expect for metal detectors?

- Q: How do I reduce false rejects caused by product effect?

- Q: Are metal detectors or X-ray systems better?

- Contact / View Product

- See the G5020 in your line — talk to us

- Authoritative references and further reading

- Final note

- Good metal detectors are an investment in safety and brand protection

Compliance Guide: Good Metal Detectors and Food Standards

Why good metal detectors are a foundation of food safety

Metal contamination is one of the most common physical hazards in food production. Effective detection and rejection systems protect consumers, reduce costly recalls, and preserve brand reputation. Good metal detectors not only identify ferrous, non-ferrous and stainless-steel contaminants, but must also integrate with quality management systems, meet regulatory expectations, and be maintainable on busy production lines. Once compliance is confirmed, consider integrating the G5020 with multihead weighers. This integration will streamline the process and ensure seamless rejects, improving overall efficiency and minimizing manual intervention in the production line.

Regulatory landscape: What food processors must know about metal detection

Key standards and expectations for using good metal detectors

Food manufacturers are held to national and international safety standards that explicitly or implicitly require control of physical contaminants. These include ISO 22000 (food safety management), Codex Alimentarius guidelines, and region-specific frameworks such as the US Food and Drug Administration (FDA) regulations and the EU food safety rules. Retailer standards (BRCGS, IFS) also list strict requirements for metal detection and verification.

Regulatory authorities expect documented hazard analysis (HACCP), validated controls for critical control points (CCPs), and routine verification. Good metal detectors must therefore be validated, regularly tested, and included in the HACCP plan or equivalent safety system.

How to choose good metal detectors for food production

Key selection criteria to meet compliance and operational goals

Choosing the right equipment involves balancing detection sensitivity, throughput, product effect management, hygiene design, and traceability. When evaluating good metal detectors, consider:

- Detection sensitivity by metal type (ferrous, non-ferrous, stainless) and product effect.

- Conveyor and aperture design to reduce false rejects and contamination sources.

- Cleanability and ability to quickly disassemble for sanitation without tools.

- Integration with reject mechanisms, PLCs, and data logging systems for audit trails.

- Validation documentation and compliance with third-party standards (e.g., BRCGS).

G5020 Food Metal Detector Manufacturer for Rejecting Defective Products

Product overview and why it's a strong choice among good metal detectors

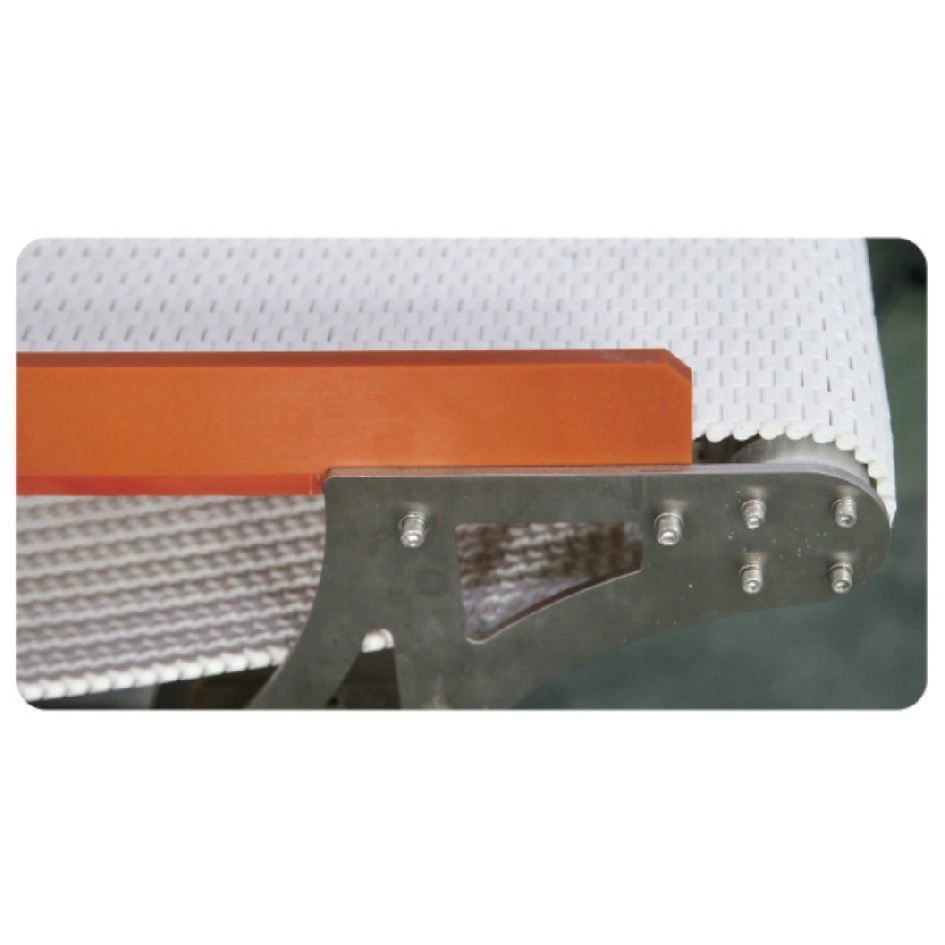

The 5020 Multi-Frequency Metal Detector features a specialized conveyor belt that minimizes contamination sources, ensuring smooth operation and high detection sensitivity. Its design allows for easy disassembly and maintenance. This metal detector is ideal for detecting metal contaminants in a wide range of industries, including food, pharmaceuticals, condiments, plastics, electronics, textiles, toys, and more.

The G5020 Food Metal Detector Manufacturer for Rejecting Defective Products is specifically engineered to support rigorous food safety programs. Multi-frequency operation improves detection across a broad set of products—especially those with high product effect—while hygienic conveyor design reduces bacterial harborage points and simplifies cleaning procedures.

Installation and hygienic design: reduce contamination risk

Best practices for installing good metal detectors on food lines

Proper installation directly impacts detector performance and compliance. Follow these guidelines when installing good metal detectors:

- Position detectors after processes where metal fragments are most likely to occur (e.g., grinders, mixers, or packaging seaming machines).

- Ensure stable, vibration-free mounting and consistent product presentation across the aperture.

- Maintain consistent product height and orientation to reduce product effect variability.

- Design conveying surfaces and frames from food-grade, corrosion-resistant materials and avoid flat surfaces that trap residue.

- Provide sanitary quick-release fasteners or tool-less disassembly where possible to speed cleaning while preserving calibration.

Validation, testing and verification of good metal detectors

How to validate sensitivity and document compliance

Validation must be demonstrable and repeatable. A robust validation protocol should include:

- Baseline sensitivity tests with certified test pieces (varying sizes and metal types).

- Product effect tests using representative product at production speed and settings.

- Periodic verification checks (daily/shift/monthly) with recorded results kept for audits.

- Simulated contamination runs to verify reject functionality and downstream handling.

Validation paperwork should be retained as evidence for auditors and include equipment settings, environmental conditions, and responsible personnel signatures. Good metal detectors designed for compliance, such as the G5020, typically provide programmable test routines and digital logs to simplify this process.

Comparing detector performance: a practical table

Sensitivity, hygiene and operational factors

| Attribute | Standard Single-Frequency Detector | G5020 Multi-Frequency Food Metal Detector |

|---|---|---|

| Detection sensitivity (stainless steel) | Moderate | High (multi-frequency improves stainless detection) |

| Product effect handling | Limited; higher false rejects on wet/fatty products | Advanced compensation for diverse product effects |

| Hygienic design | Basic; may have crevices | Specialized conveyor, easy disassembly, reduced contamination points |

| Integration & data logging | Standard outputs, limited traceability | Comprehensive logging, reject verification, PLC integration |

| Maintenance effort | Higher; more downtime for cleaning | Lower; quick disassembly and maintenance features |

| Typical industries | Baked goods, dry snacks | Food, pharmaceuticals, condiments, electronics, textiles |

Operational strategies to minimize false rejects and maximize uptime

Calibration, product setup and training tips

To get the most from good metal detectors, implement clear SOPs:

- Use product-specific presets and lock them to prevent unauthorized changes.

- Train operators on how product effect influences sensitivity and when to run validation tests.

- Log all rejects with cause codes for trend analysis — excessive false rejects often indicate mechanical issues, dirty conveyors, or misaligned settings.

- Schedule preventative maintenance and keep spare parts on hand (belts, sensors, conveyor components).

Integration with multihead weighers and production lines

Why coordination matters for compliance and yield

Good metal detectors should be part of an integrated quality control chain. When placed downstream of a multihead weigher, the metal detector protects both consumer safety and packaging machinery. Integration benefits include automated reject confirmation, reduced human error, and combined data for HACCP records. The G5020 is engineered for straightforward integration with common packaging and weighing equipment, reducing installation complexity.

Case examples: real-world advantages of using compliant detectors

Practical outcomes from implementing good metal detectors

Companies that adopt detectors designed for hygiene, sensitivity, and ease-of-use report:

- Reduced recalls and customer complaints due to physical contaminants.

- Lower downtime from simplified cleaning and faster maintenance.

- Improved audit readiness from automated logs and validation routines.

- Higher yield through reduced false rejects and better product effect handling.

Brand advantages and why G5020 stands out among good metal detectors

How the G5020 aligns with compliance, operations and ROI

The G5020 Food Metal Detector Manufacturer for Rejecting Defective Products offers a balanced, compliance-focused solution. Key brand advantages include:

- Multi-frequency detection to increase sensitivity across metal types and problematic products.

- Hygienic conveyor and quick-disassembly design that simplifies cleaning and reduces microbial risk.

- Comprehensive data logging and easy integration for audit trails and HACCP documentation.

- Designed for a broad range of industries — from food to pharmaceuticals — enabling standardization across sites.

For procurement teams, these features translate into fewer production interruptions, clearer compliance evidence, and better long-term value compared with basic detectors.

Maintenance checklist for long-term compliance

Daily, weekly and monthly tasks to keep good metal detectors audit-ready

- Daily: Visual inspection, quick sensitivity check with manufacturer-recommended test pieces, verify reject operation.

- Weekly: Clean conveyor and frame, inspect belts and guide rails for wear, review logged rejects.

- Monthly: Full sensitivity validation at production speed, firmware/parameter backups, review calibration certificates.

FAQ — Frequently Asked Questions about good metal detectors and food standards

Q: How often should metal detectors be tested?

A: At minimum, perform a functional check at every shift start and a full sensitivity validation monthly or whenever product, speed or settings change. Follow your HACCP plan and customer or retailer requirements which may specify more frequent verification.

Q: Can metal detectors find all types of metal?

A: No detector is perfect for every scenario, but multi-frequency detectors (like the G5020) improve detection of ferrous, non-ferrous and stainless steels. Detection capability also depends on product effect, aperture size, and conveyor design.

Q: What documentation do auditors expect for metal detectors?

A: Auditors will look for validation records, daily/shift verification logs, maintenance records, reject logs, and evidence that the metal detector is included in the HACCP or food safety plan.

Q: How do I reduce false rejects caused by product effect?

A: Use product-specific presets, ensure consistent product presentation, consider multi-frequency detectors to improve signal discrimination, and train operators to recognize and troubleshoot product effect issues.

Q: Are metal detectors or X-ray systems better?

A: It depends on the contamination risk and product characteristics. Metal detectors are highly effective for most metal contaminants and are cost-efficient. X-ray systems detect denser non-metal objects and can identify glass, stone and bone but are costlier and may have higher energy and maintenance demands. Many processors use a combination depending on product and risk profile.

Contact / View Product

See the G5020 in your line — talk to us

To evaluate how the G5020 Food Metal Detector Manufacturer for Rejecting Defective Products fits your operation, contact our sales and technical team for a site assessment, demo, or quotation. We provide validation support, integration engineering, and training to help you achieve and document compliance quickly.

Authoritative references and further reading

These sources provide official standards and guidance referenced in this guide:

- ISO 22000 — Food safety management systems: https://www.iso.org/iso-22000-food-safety-management.

- Codex Alimentarius: http://www.fao.org/fao-who-codexalimentarius/en/

- U.S. Food and Drug Administration (FDA) — Food Safety Modernization Act (FSMA): https://www.fda.gov/food/food-safety-modernization-act-fsma

- European Commission — Food safety: https://ec.europa.eu/food/

- BRCGS Global Standards: https://www.brcgs.com/standards/

- AOAC International — Official methods and guidance: https://www.aoac.org/

Final note

Good metal detectors are an investment in safety and brand protection

Implementing well-selected, validated and well-maintained metal detectors like the G5020 strengthens your food safety system, protects consumers, and reduces the risk of costly recalls. Prioritize hygiene-focused design, thorough validation, and integration with quality systems to ensure compliance and operational excellence.

What are the application scenarios of pouch packing machine?

ROI of Investing in Good Metal Detectors for Food Safety

Where to Buy automatic check weighing equipment

What is metal detector machine ?

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei