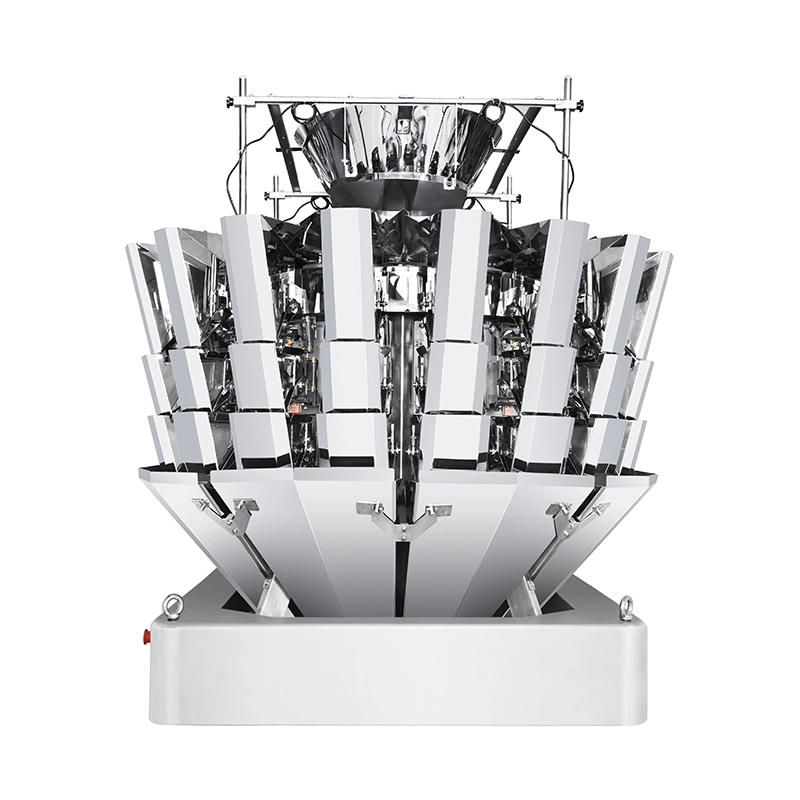

Kenwei Multihead Weigher Packing Machine — Fast, Accurate, Reliable

Overview

Kenwei multihead weigher packing machines combine industry-leading speed and accuracy with easy operation and reliable construction. Designed for food and non-food applications such as snacks, frozen foods, nuts, candies, granules, and hardware, our machines help manufacturers increase throughput while reducing giveaway and labor costs.

Why Choose Kenwei?

High Speed & High Precision

Kenwei multihead weighers are engineered for fast feeding and ultra-precise weight control. Advanced weighing algorithms and stable mechanics minimize product giveaway and ensure consistent pack weights even at high line speeds.

Flexible & Customizable

We offer modular designs and customization to match your product, pack format, and production layout. Whether you need different hopper sizes, special dosing systems, or integration with filling and sealing lines, Kenwei provides tailored solutions.

One-Stop Automated Solutions

As a full-service manufacturer, Kenwei supplies multihead weighers along with metal detectors, linear weighers, and check weighers for a complete automated packaging line. We support design, manufacturing, installation, training, and after-sales service to keep your line running smoothly.

Key Benefits

- Increase production speed without sacrificing accuracy- Reduce product giveaway and packaging cost- Easy-to-use touch screen and simple recipe setup- Durable stainless-steel construction for hygiene and long life- Quick changeover for different products and bag types- Expert technical support and fast service from Guangdong Kenwei

Trusted Manufacturer

Located in Fusha High-tech Industrial Park, Zhongshan, Guangdong, Kenwei is committed to developing reliable weighing and packing equipment. Our customers value our thoughtful service, fast response, and proven performance in demanding production environments.

Get Started

Upgrade your packaging line with Kenwei multihead weighers for faster output, better accuracy, and lower costs. Visit https://www.kenweigroup.com/ or contact our sales team to discuss your product and request a custom solution.

Detailed display

Our Certifications

OIL CERTIFICATE OF CONFORMITY

Scale hopper-Utility Model Patent Certificate

Mixing weighing method and mixing equipment - patent certificate

Frequently Asked Questions

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

14 Head Multihead Weigher Packaging Machine for Weighing and Packaging Dumplings Wontons

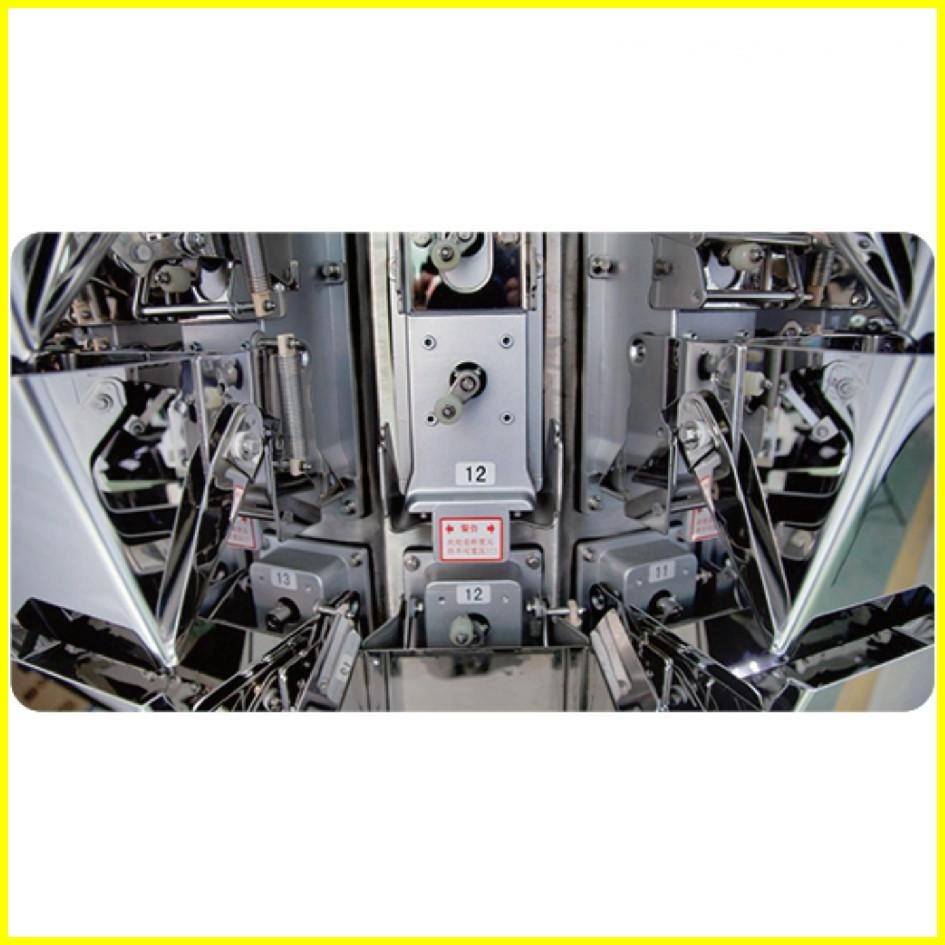

The weighing sensor has high-precision, high-standard professional performance and adopts intelligent multi-sampling stable mode to significantly improve weighing accuracy. It also has an intelligent fault alarm function, making maintenance more efficient and convenient. The equipment supports high-speed wrong material unloading, effectively avoiding material blockage. The overall structure adopts a highly integrated modular design, integrates CAN bus technology, and applies Modbus industrial standard communication protocol to achieve seamless integration of the combined weighing system and the packaging machine.

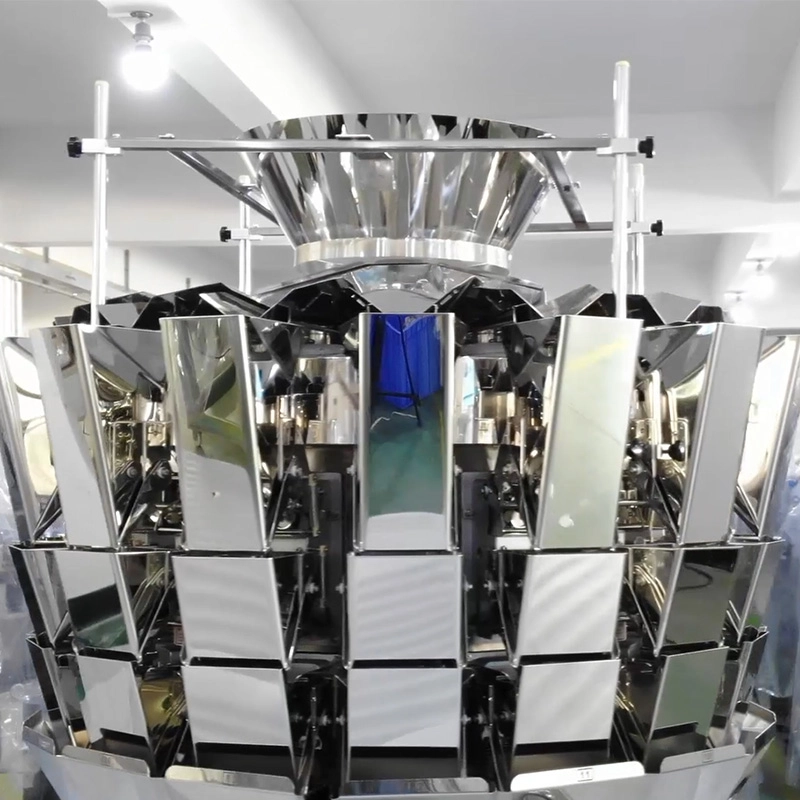

High Precision 3-Layer 18-Head Standard Weigher for Accurate and Efficient Weighing

The High-Precision 3-Layer 18-Head Standard Weigher is designed for accurate weighing of a wide range of materials, including granular, flake, round, irregular, and puffed items like nuts, seeds, candies, and snacks. It features a separate vibration plate for mixed material applications, a Ling-shaped hopper for faster and more concentrated discharge, a memory bucket for improved accuracy, and an integrated chassis for enhanced stability. Ideal for high-precision, efficient weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei