50g Small granule and running speed is 45 packs/min

Food safety is the primary requirement for consumers to choose food. The hygienic and safety standards for the food packaging process and packaging materials are becoming more and more stringent. For example, high-end tea is often easily damped or absorbs tiny impurities during the production and packaging process, affecting the product. quality, and even directly destroy the safety of tea.

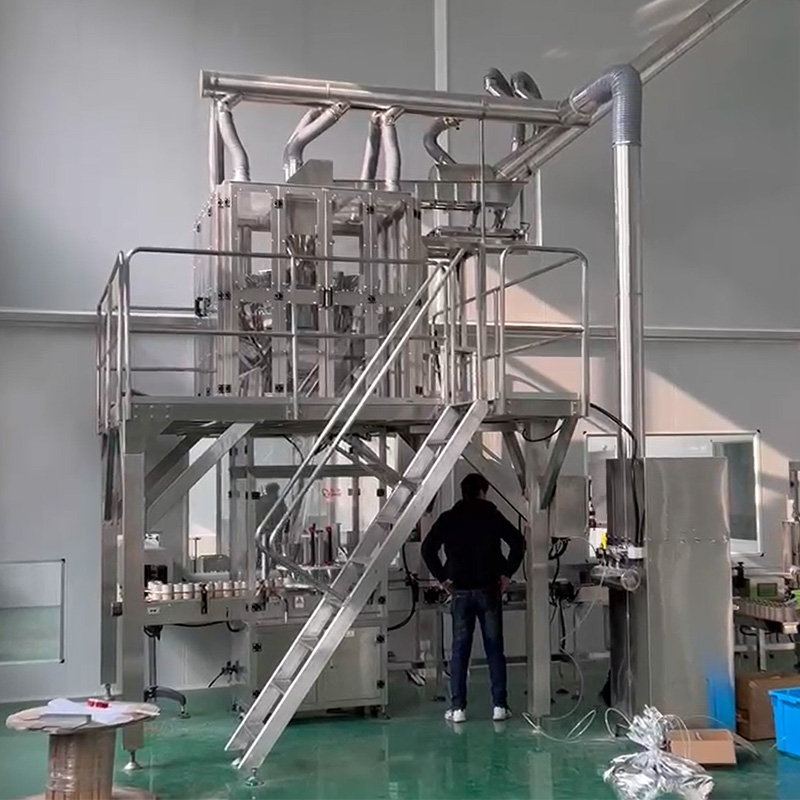

With the emergence of spinning aluminum cans, tea packaging has been greatly improved in terms of appearance design and product protection. However, in the face of the large-scale exposure of the packaging line, how should we deal with the need to ensure the safety and cleanliness of materials and maintain efficient weighing and packaging?In response to customer requirements, Guangdong Kenwei customized a personalized automatic weighing one-to-two can packaging system , allowing the entire set of equipment to work in an "independent office". At the same time, an air purification and ventilation system are added to ensure that the tea leaves are isolated from most of the fine impurities during the weighing and filling process and keep the air dry, thereby improving the output of product safety and quality.

The system is composed of Guangdong Kenwei's new II series 14-head standard multihead weigher and material diverter with C1000 high-precision check weigher , and custom-made acrylic material sealing chamber is added, which can not only observe the operation of materials but also ensure the packaging. Environmental safety and hygiene.It is widely used in the quantitative weighing of raisins, tea, coffee beans, and other snack foods, hardware, plastic pellets, and other granular materials, and can store 100 sets of parameter settings to achieve different quantitative application requirements of various materials.

Customer's request

●The actual single material measurement is 50 grams.

●The setting precision is 0.5 for upper deviation and 0 for lower deviation.

●The actual running speed is 45 packs/min.

Food safety has always been an important lifeline running through the entire food industry, and packaging safety is an indispensable part of it. Guangdong Kenwei has 16 years of experience in the professional custom multi-head combination weigher industry, using food-grade 304 industry standard materials, people-oriented, starting from quality, and customizing your exclusive high-end safe weighing and packaging helper.

About Solution suggestions

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei