China’s Packaging Machinery Industry Growth and Kenwei’s Role in Intelligent Manufacturing

China’s packaging machinery industry is experiencing rapid growth, driven by rising consumer demand, infrastructure development, and supportive policies. Guangdong Kenwei Intellectualized Machinery Co., Ltd. is leading the way with intelligent weighing and packaging solutions, helping manufacturers achieve efficiency, innovation, and sustainable growth.

Market Growth of China’s Packaging Machinery Industry

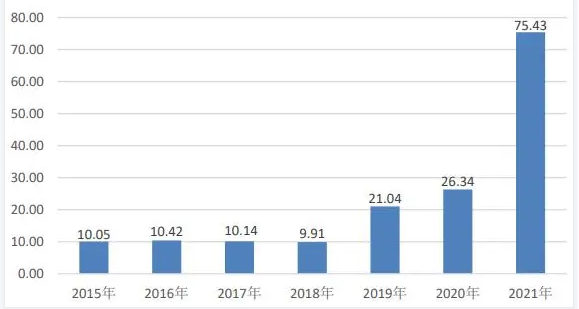

According to the 2023-2029 China Packaging Machinery Industry Market Competition Strategy and Investment Strategy Planning Report released by Market Research Online, the market size of China’s packaging machinery industry has shown remarkable growth. From 2015 to 2020, the market expanded from 112.52 billion yuan to 167.73 billion yuan, achieving a growth rate of 49.5% with a return rate of 5.1%.

With the improvement of infrastructure, rising consumer demand, and favorable government policies, the industry continues to expand. It is projected that China’s packaging machinery market will reach 233.86 billion yuan in the next five years, providing vast opportunities for enterprises to accelerate intelligent transformation.

Challenges and Opportunities Ahead

While the industry outlook remains promising, enterprises face greater scrutiny from the market and end-users. Manufacturers must adopt stricter standards and prioritize intelligence, environmental protection, and energy efficiency. Only by embracing innovation can companies achieve higher production efficiency and deliver high-quality packaging equipment that meets global standards.

Kenwei: Driving Innovation in Intelligent Packaging

Guangdong Kenwei Intellectualized Machinery Co., Ltd., with 18 years of experience, has become a leading global manufacturer of automatic quantitative weighing and packaging machinery. Guided by customer needs and market demand, Kenwei has established itself as a trusted producer of combination weighers, linear weighers, check weighers, and metal detector machines with a strong international presence.

Intelligent "Cloud Configuration" System

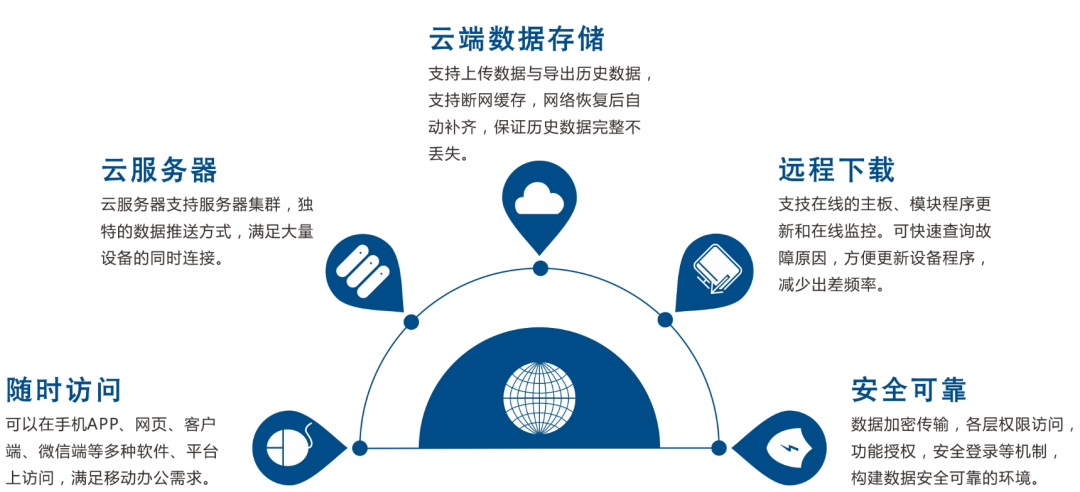

Kenwei’s Cloud Configuration intelligent interconnection system represents a milestone in digital packaging innovation. Through a modular design, CAN bus technology, Modbus communication protocols, and IoT integration, it enables remote monitoring, automated data collection, and intelligent control of packaging lines via computers, smartphones, and tablets.

This innovation effectively combines weighing and packaging technology with advanced automation, bringing the packaging industry into a new digital era.

Customer-Centered Service

Kenwei is also committed to customer satisfaction and service excellence. The company provides a two-year warranty for self-developed products, supported by a comprehensive service management system, customer-focused solutions, and efficient after-sales support. These efforts reflect Kenwei’s values of integrity, responsibility, and continuous innovation.

Future Outlook

The independent development and industrialization of high-end packaging equipment remain a top priority under national industrial policies. Looking ahead, Guangdong Kenwei will continue to focus on efficiency, flexibility, customization, and intelligence, aiming to provide global customers with more advanced and reliable automatic weighing and packaging machinery.

By embracing innovation and customer-centric development, Kenwei is not only driving the growth of the packaging machinery industry but also contributing to China’s journey toward intelligent, sustainable, and high-quality manufacturing.

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei