The Role of Multi-Head Combination Weighers in Modern Packaging Industry

A multi-head combination weigher is a high-precision weighing solution widely used in the food, pharmaceutical, cosmetics, hardware, and electronics industries. By using multiple weighing heads and advanced computer control systems, this equipment provides fast, accurate, and flexible weighing solutions. With growing demand for safe, efficient, and intelligent packaging, the adoption of multi-head weighers is rapidly increasing, offering strong market potential and broad development prospects.

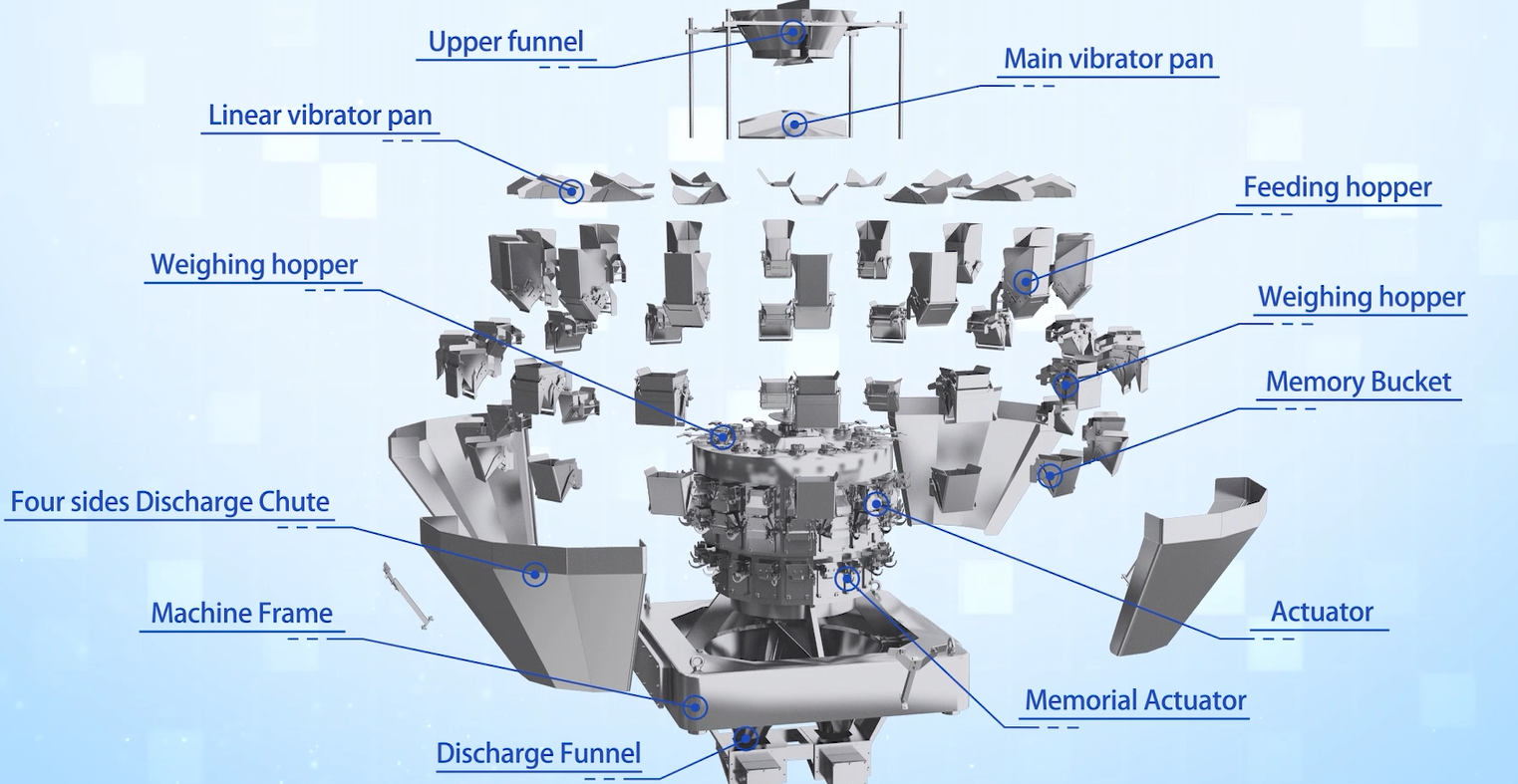

What is a Multi-Head Combination Weigher?

A multi-head combination weigher is a specialized weighing device equipped with multiple independent weighing units. Each unit works simultaneously to capture precise weight data, which is then processed through a central computer control system. The system analyzes the results and provides the most accurate weight output, ensuring reliability and consistency in packaging.

Advantages of Multi-Head Combination Weighers

Compared with traditional single-weighing equipment, multi-head weighers offer significant advantages:

-

High Efficiency – Multiple weighing units operate simultaneously, greatly improving production output.

-

Multifunctionality – Supports static weighing, dynamic weighing, and classification statistics.

-

Flexibility – Configurable with different quantities and specifications of weighing heads to meet diverse production needs.

-

High Reliability – Built with advanced technology and durable materials, ensuring long service life and stable performance.

Applications and Market Prospects

Multi-head weighers are extensively used across industries, with the food packaging industry being the largest market. They are particularly valuable in processing snacks, grains, frozen foods, confectionery, and fresh produce.

As global consumers demand higher standards of food safety and product quality, the adoption of automatic weighing and packaging machines will continue to rise. With ongoing technological innovation and industrial demand, the market prospects for multi-head combination weighers remain highly promising.

Future Development Trends

The evolution of multi-head weigher technology is expected to follow several key directions:

-

Enhanced Functions – Integration of intelligent features such as AI-driven controls and voice recognition to improve usability.

-

Faster Data Processing – Improved computing capabilities to deliver quicker, more accurate results.

-

Greater Adaptability – Automatic parameter adjustments to optimize performance in different environments.

Kenwei – Professional Manufacturer of Multi-Head Weighers

Guangdong Kenwei Intellectualized Machinery Co., Ltd. has specialized in the development and production of quantitative weighing and packaging equipment for over 18 years. With a strong focus on innovation, Kenwei provides:

-

Multi-head combination weighers

-

Linear weighers

-

Metal detector machines

-

Check weighers

-

Electronic counting machines

-

One-stop automatic weighing and packaging machine solutions

Kenwei remains dedicated to delivering intelligent, efficient, and reliable food packaging equipment that meets the diverse needs of customers worldwide.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei