Kenwei Multihead Weigher Factory – High Precision & Speed Weighing Machines

Kenwei is a leading manufacturer specializing in high-quality multihead weighers designed to deliver precise and efficient weighing solutions for various industries. Located in Guangdong’s Fusha High-tech Industrial Park, Kenwei combines advanced technology and decades of expertise to produce weighing machines that stand out for their speed, accuracy, and reliability.

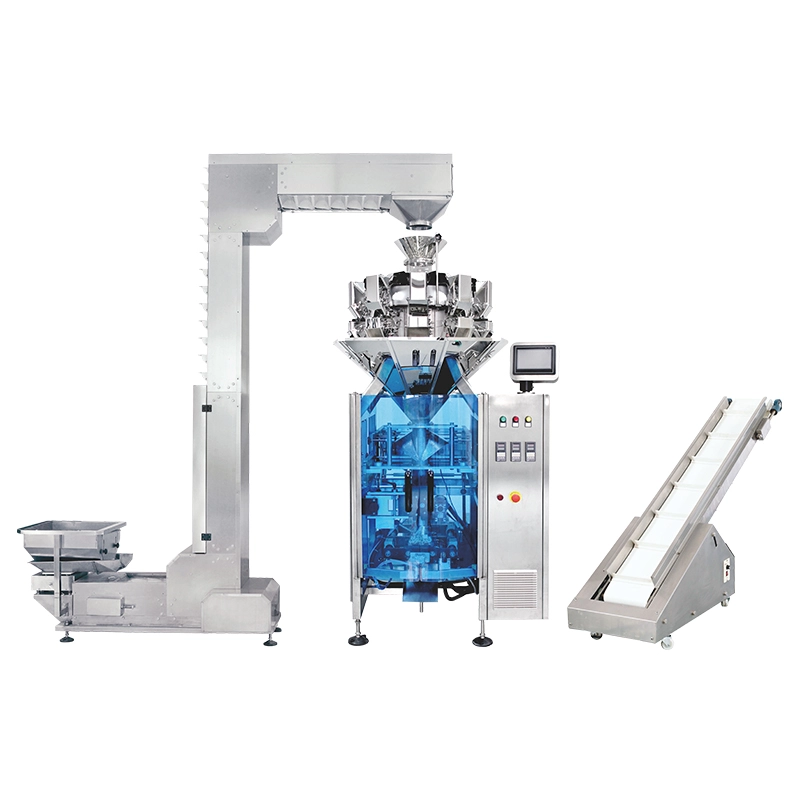

Our multihead weighers are engineered to handle diverse products, from snacks and nuts to frozen foods and hardware, ensuring consistently accurate weights to minimize product giveaway and improve packaging efficiency. The machines integrate seamlessly into your production line, offering customizable configurations based on your specific needs.

At Kenwei, we don’t just manufacture machines; we provide complete automated weighing and packaging solutions. Our one-stop service covers everything from design and manufacturing to installation, staff training, and responsive after-sales support, ensuring your operation runs smoothly.

Choosing Kenwei means investing in equipment that boosts productivity, reduces labor costs, and enhances product quality. Our commitment to innovation and customer satisfaction has earned us a strong reputation in the packaging machinery industry worldwide.

Visit (https://www.kenweigroup.com/) to discover how our multihead weighers can add value to your business with reliable performance and tailored solutions.

Detailed display

Certificate display

Ringier Technology Innovation Award

Executive Director Unit of China Food and Packaging Machinery

ICR Polska/VC/LU201102 Working Platform

Frequently Asked Questions

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

If you have any questions about our goods or services, please feel free to contact us.

Super High Precision Mini Multihead Weigher with 0.3L Hopper for Small Granule Weighing

The Super Mini Multihead Weigher features a specialized high-precision sensor with a resolution of up to two decimal places. Equipped with an ultra-small 0.3L hopper, it is ideal for accurately weighing materials that require symmetrical weight precision, such as MSG, chocolate beans, Chinese herbal pieces, and other small granules. This weigher ensures precise and consistent quantitative measurement of fine particles.

1 Head Linear Weigher with Two-Layer Belt Vibrating

Fully Automatic Cup Weighing and Packaging Machine for Snack Foods JW-B23

The system consists of a vibrating feeder, a Z-type conveyor, a 14-head combination scale, a material diverter, an automatic cup drop device, a cup mold conveyor, a capping machine and a finished product conveying device. It has high-precision filling capabilities and is suitable for a variety of mold cup combinations. It can realize fully automatic operations of feeding, weighing, filling, bag making, printing and finished product output, and is suitable for a wide range of materials with high production efficiency.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei