Kenwei Filling Machines: Fast, Accurate Automated Weighing & Packing

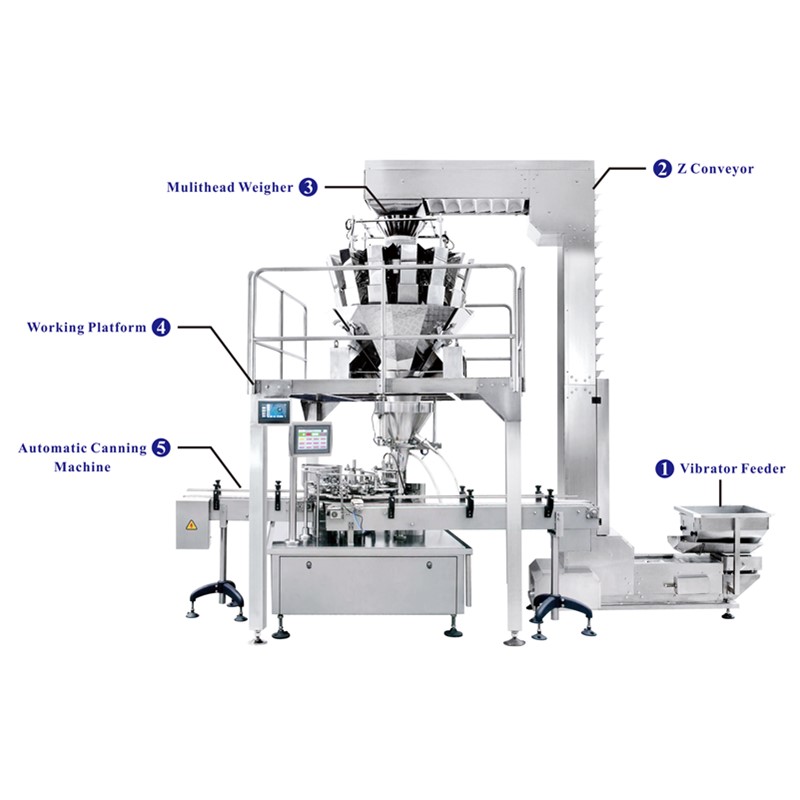

The Kenwei Automatic Canning and Weighing Filling System offers a fully integrated solution for efficient food packaging. Featuring a multihead weigher, Z-type conveyor, vibrator feeder, and capping machine, it automates feeding, weighing, filling, and labeling with high accuracy. Perfect for snacks, puffed foods, fruits, hardware, and granular materials in cans. Ideal for modern production lines.

Kenwei Filling Solutions: Precision and Efficiency for Every Packaging Need

Upgrade your production line with Kenwei’s advanced filling solutions. As a trusted leader in multi-head weighers, we deliver filling systems that offer unmatched speed and precision to ensure every package meets your highest quality standards. Serving industries from food to pharmaceuticals, our machines support accurate, reliable, and hygienic filling for powders, granules, or irregular-shaped products.

Backed by over a decade of innovation, Kenwei’s filling equipment seamlessly integrates into your automated weighing and packaging lines. Featuring user-friendly controls, modular designs, and robust safety features, our solutions minimize downtime and maximize productivity. Every machine is customized to fit your unique requirements, whether you need high-speed operation or delicate handling for sensitive products.

Located in the Fusha High-tech Industrial Park in Zhongshan, China, Kenwei combines comprehensive capabilities—from design and engineering to installation, technical training, and ongoing support. Our reputation for thoughtful, responsive service means you’ll always feel valued, supported, and confident in your investment.

Choose Kenwei for your filling needs and experience the reliability, efficiency, and excellence that only a global leader in automated packaging technology can provide.

For more information or to request a tailored solution, visit our website: (https://www.kenweigroup.com/)

Product Image

Certificate display

2021 Outstanding Contribution to Enterprise Tax Payment Third Prize

TOW Series Combination Weigher-Patent Certificate of Appearance Design

ICR Polska/VC/LU201107 Check Weigher

FAQ

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

Automatic 8-Track Electronic Counting and Filling Packaging Machine

This counting machine offers a two-channel, eight-track electronic system with adjustable height, supporting bottle heights from 20 to 100mm. It requires no reset during fast line changes, making it perfect for counting products of various shapes. With a maximum speed of 4,000 particles per minute, it is ideal for pharmaceutical, food, chemical, plastic, healthcare, and other industries, delivering efficient and precise counting.

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

The Kenwei Automatic Canning and Weighing Filling System offers a fully integrated solution for efficient food packaging. Featuring a multihead weigher, Z-type conveyor, vibrator feeder, and capping machine, it automates feeding, weighing, filling, and labeling with high accuracy. Perfect for snacks, puffed foods, fruits, hardware, and granular materials in cans. Ideal for modern production lines.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei