Kenwei Check Weigher Metal Detector

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Product Description

Kenwei Check Weigher Metal Detector – Reliable Precision for Every Package

Ensure your products meet the highest standards with the Kenwei check weigher metal detector. Manufactured by Guangdong Kenwei Intellectualized Machinery Co., Ltd., a leading name in automated weighing and packaging solutions, this advanced device combines accurate weight verification and sensitive metal detection in one seamless system. Born from years of expertise in multi-head weighers and weighing technology, the Kenwei check weigher metal detector brings together speed, precision, and reliable performance, providing peace of mind for manufacturers and consumers alike.

Our state-of-the-art machine is engineered for high-speed production lines, featuring a user-friendly interface and intelligent controls. It swiftly identifies and removes underweight or overweight products and detects metallic contaminants, ensuring only safe, compliant goods reach your customers. Kenwei’s comprehensive capabilities cover everything from design development to installation and after-sales support, guaranteeing customers a full, worry-free service experience.

Located in Fusha High-tech Industrial Park, Zhongshan City, China, Kenwei stands out for innovation and exceptional customer care. We tailor automated packaging and weighing systems to your unique needs—supporting customized solutions for a wide range of industries, including food, pharmaceuticals, and logistics.

Choose Kenwei check weigher metal detector for uncompromised safety, industry-leading precision, and a trusted partnership dedicated to your success.

Product Image

Certificate display

Finished product converyor

Innovation award

Weiging and packging line

Frequently Asked Questions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Combined weighing and packaging machine with screw feeder for powder materials

The Kenwei combined weighing and packaging machine with screw feeder is ideal for powder packaging. This advanced weighing and packaging machine of powder ensures high precision and efficiency, making it your top choice power packaging machine for powder materials.

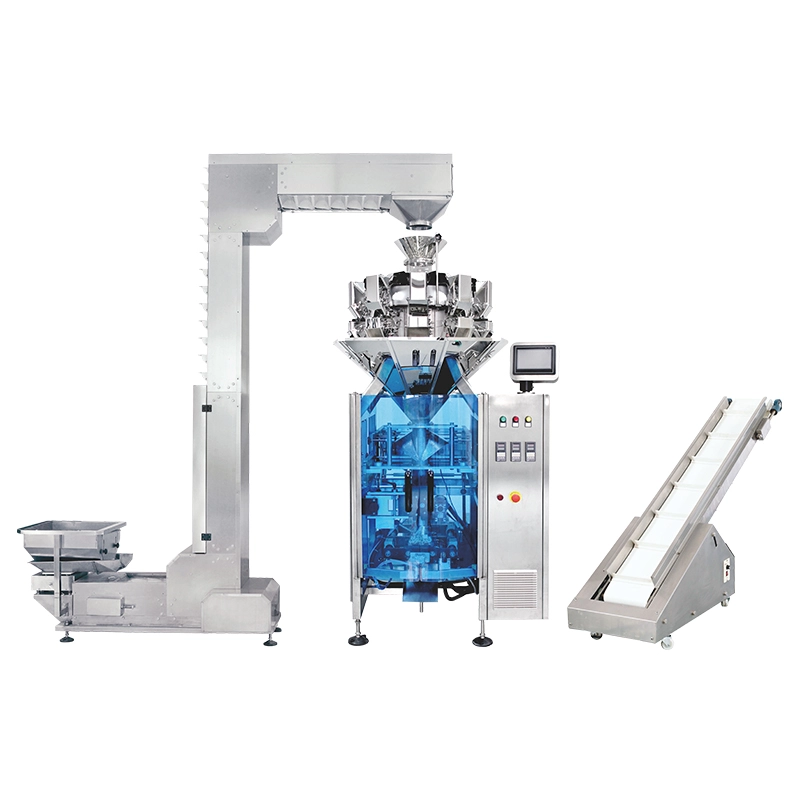

Combined Multihead Weighing Weigher and Packaging Machine with Z Conveyor JW-B4

The JW-B4 Combined Multihead Weighing and Packaging Machine with Z Conveyor is a compact, fully automatic solution ideal for packing snacks, nuts, candies, pet food, frozen products, hardware, and more. It integrates feeding, weighing, filling, sealing, and labeling with high precision and speed. Suitable for a wide range of materials, it’s perfect for space-limited production lines.

14-Head Multihead Weigher for Weighing Anchovy Fish with Precision

The 14-Head Anchovy Fish Multihead Weigher features a single-door special hopper and an anti-sticking design, ensuring smooth material flow, preventing clogs, and maintaining weighing accuracy. It is ideal for weighing highly sticky and high-content materials, such as spicy fish larvae, pickled duck, and other snack foods.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei