High-Precision Checkweigher for Efficient Product Weight Sorting

Discover Kenwei’s high-precision checkweigher designed for real-time weight detection and sorting. Improve production efficiency, accuracy, and cost-effectiveness for food, pharmaceutical, and industrial packaging lines.

A checkweigher machine is an essential piece of equipment for modern production lines, designed to automatically sort products based on weight. Widely used in the food, pharmaceutical, aquatic products, and poultry industries, it replaces manual weighing, significantly improving production efficiency, ensuring accuracy, reducing labor requirements, and lowering costs.

How a Checkweigher Works

The industrial weight sorting system operates through a coordinated process involving the weight sensor, AD module, PLC (Programmable Logic Controller), and sorting mechanism:

-

Weight Detection – The weight sensor converts product weight into an analog voltage signal.

-

Signal Conversion – The AD module transforms this signal into digital weight data, representing the real-time weight of the product on the conveyor belt.

-

Data Processing – The PLC reads and analyzes this data, calculating the product’s actual weight as it moves across the weighing belt.

-

Sorting Decision – If the product is outside the preset weight range, the PLC triggers the reverse belt action, automatically removing non-compliant items.

Applications

Kenwei’s online weight checking machines are suitable for a wide range of packaging formats, including:

-

Bulk paper bags

-

Plastic packaging

-

Carton boxes

-

Metal film packaging

They ensure high-speed, high-precision operation in stable working conditions.

Key Features

-

High Accuracy & Speed – Delivers precise weighing results at rapid throughput.

-

LAN & Serial Communication – Optional RS232 or RS485 connectivity for seamless integration.

-

Data Export Function – USB port allows export of package weight records and production logs.

-

User-Friendly Operation – Intuitive touch screen for easy parameter setting.

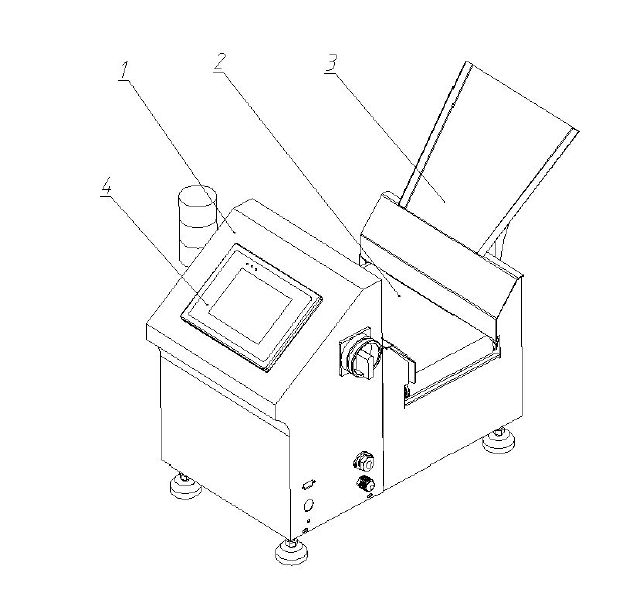

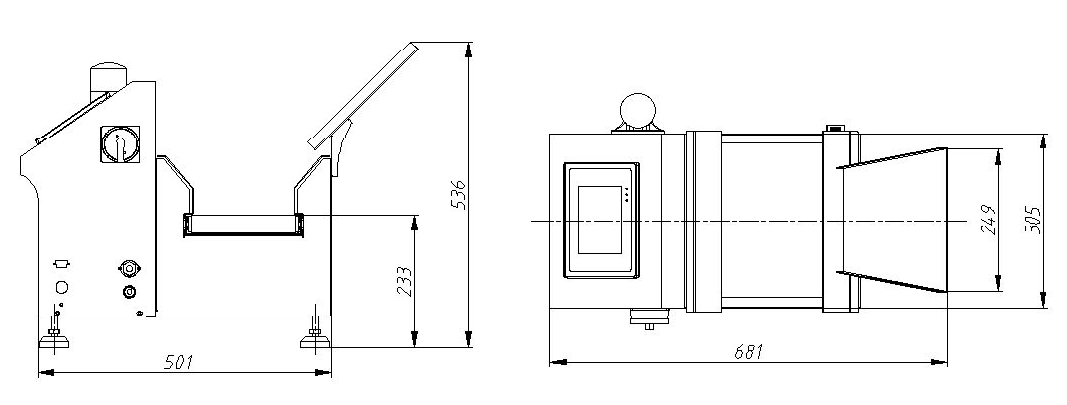

Structural Components

The basic structure of the checkweigher includes:

-

Electric Box – Houses the PLC for data processing and motor control.

-

Weighing Belt – Equipped with a weight sensor and AD module for accurate measurement.

-

Material Receiving Plate – Buffers product impact and guides it onto the weighing belt.

-

Touch Screen Interface – Simplifies operation and real-time monitoring.

Why Choose Kenwei’s Checkweigher

Kenwei’s checkweighers combine fast detection, high measurement accuracy, and scalable performance, offering cost-effective solutions for inline weight inspection and product sorting in various industries.

About Solution suggestions

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei