Kenwei Showcases Cutting-Edge Weighing Technology at ProPak China 2020

From Nov. 25–27, 2020, Guangdong Kenwei showcased its newest smart weighing and packaging technologies at the 26th ProPak China. With an impressive booth and four new products on display, Kenwei once again proved its leadership in automated processing and packaging innovation.

From November 25th to 27th, 2020, the 26th ProPak China was successfully held at the National Convention and Exhibition Center in Shanghai. In collaboration with the China Food and Packaging Machinery Industry Association and China Packaging and Food Machinery Co., Ltd., this event was held concurrently with the 20th FoodPack China, creating the 2020 Shanghai International Food Processing and Packaging Machinery Joint Exhibition.

This extensive event covered the entire packaging value chain—from food and liquid processing, weighing and measuring, printing and labeling, intelligent packaging equipment, e-commerce logistics, to warehousing and material distribution. It served diverse sectors including food, beverages, dairy, personal care, FMCG, pharmaceuticals, and health industries.

China’s Leading Packaging Industry Event

As one of the most prominent exhibitions in China’s processing and packaging industry, ProPak China has been running for 25 consecutive years. The 2020 edition attracted thousands of manufacturers, including over 100 international brands, showcasing cutting-edge technologies in:

-

Packaging machinery

-

Liquid and food processing

-

Label printing and flexible packaging

-

Packaging materials and containers

-

Smart manufacturing and logistics solutions

Despite challenges posed by the global pandemic, the exhibition floor remained vibrant, with high foot traffic and strong participation from exhibitors eager to display their innovations.

Kenwei Brings Innovation to the Forefront

As a global leader in intelligent weighing and packaging systems, Guangdong Kenwei Intellectualized Machinery Co., Ltd. once again stood out as a key exhibitor. With a visually stunning booth and meticulously prepared showcase, Kenwei introduced its latest smart weighing systems and auxiliary packaging equipment, drawing significant attention from attendees and industry professionals.

Kenwei, recognized for its high production capacity and wide international influence, continues to lead in automatic quantitative combination weighing equipment, exporting to over 100 countries and serving more than 1,500 clients worldwide.

Featured New Products at the Exhibition

Kenwei unveiled several new intelligent weighing solutions at ProPak China 2020:

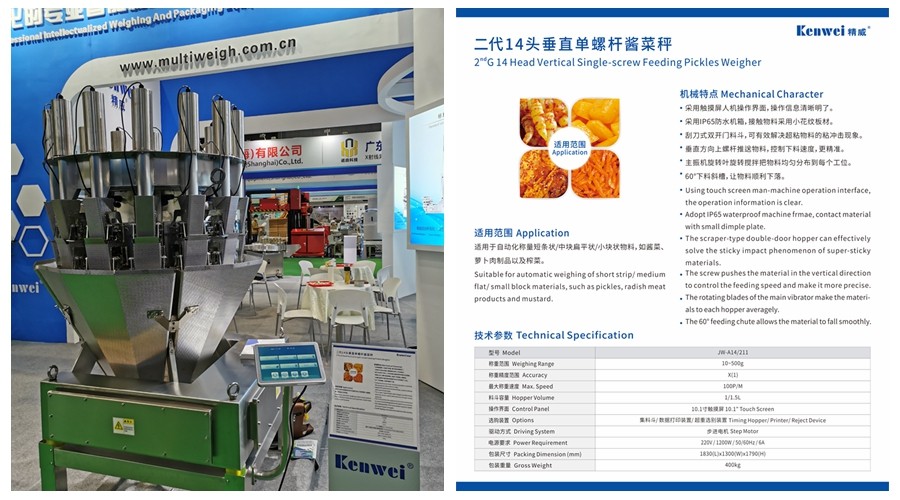

🔹 14-Head Vertical Single-Screw Feeding Pickles Weigher

Designed for sticky and pickled materials, ensuring smooth feeding and precise weighing through innovative screw feeding technology.

🔹 Automated Granular Gold Inspection and Labeling System

An integrated solution combining weighing, metal detection, and labeling functions—ideal for high-value granular products.

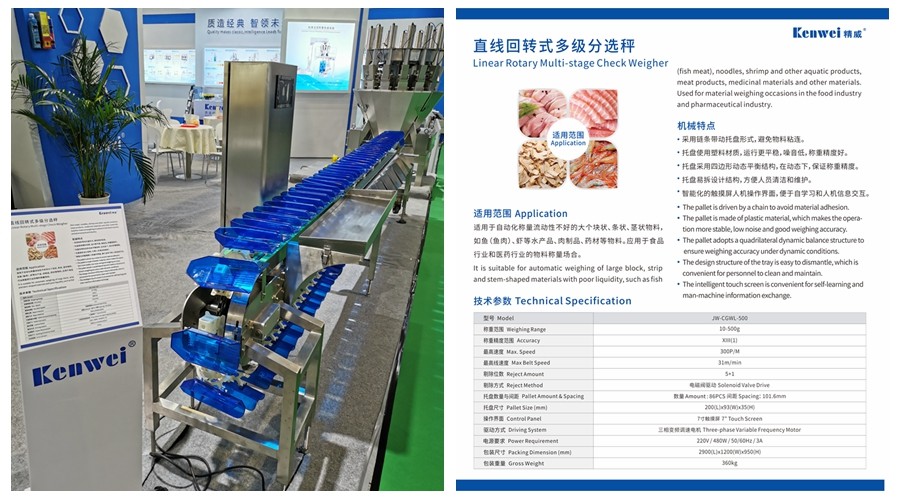

🔹 Linear Rotary Multi-Stage Check Weigher

A next-generation check weighing system designed for multi-stage sorting with high-speed rotary functions for increased efficiency.

🔹 4th Generation Three-Layer 24-Head Multihead Weigher

Engineered for high-volume and high-precision weighing, this system offers unmatched speed and accuracy for complex production environments.

Looking Ahead

By continuing to invest in technological innovation, user-centric design, and global service, Kenwei reinforces its mission to deliver efficient, intelligent, and cost-effective packaging solutions. The success at ProPak China 2020 reflects Kenwei’s unwavering dedication to driving the future of automated packaging.

About Kenwei

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is a global manufacturer specializing in intelligent weighing, packaging systems, and automation solutions. With more than 14 years of expertise, Kenwei serves industries including food, pharmaceuticals, chemicals, and hardware with high-quality, precision-engineered equipment.

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei